using mosquito hotend in heated chamber

-

Anyone using a mosquito hot end in a heated chamber with air cooling, im getting clogs and under extrusion about 3/4 the way through a benchy test prints. The only material that prints without an issue is polymaker polycarbonate, probably due to its high glass transition temp.

-

Not currently but was thinking about trying it down the line. What are your retraction settings? I had to dial way down on my direct drive BMG setup (0.2-0.4 mm) to deal with the heat creep.

-

@davidvh86 said in using mosquito hotend in heated chamber:

Anyone using a mosquito hot end in a heated chamber with air cooling, im getting clogs and under extrusion about 3/4 the way through a benchy test prints. The only material that prints without an issue is polymaker polycarbonate, probably due to its high glass transition temp.

How hot of a chamber? Do you also have a heated build plate (or does the build plate drive the chamber temperature)? What material at what temperature?

Stock fan or other fan?

Depending on your extruder setup, you may actually be having issues at the drive gears due to the chamber temperature (from personal experience).

-

@whopping-pochard

started at 1 mm went to .9 at 30mms -

@sebkritikel said in using mosquito hotend in heated chamber:

o you also have a heated build plate (or does the build plate drive the chamber temperature)? What material at what temperature?

Stock fan or other fan?yea stock fan with an independent chamber heater and bed.

Heated chamber at 60 c for abs 250c hotend. heated chamber at 30c and 240 hotend for petg. -

@davidvh86 said in using mosquito hotend in heated chamber:

@whopping-pochard

started at 1 mm went to .9 at 30mmsSeems crazy high to me, unless you're using a bowden extruder. I keep mine less than .5, but with a direct drive (BMG) setup.

Temperatures look fine for ABS, although I run ABS closer to 300°C (habits from a Stratasys machine running MG94 high-melt flow ABS).

-

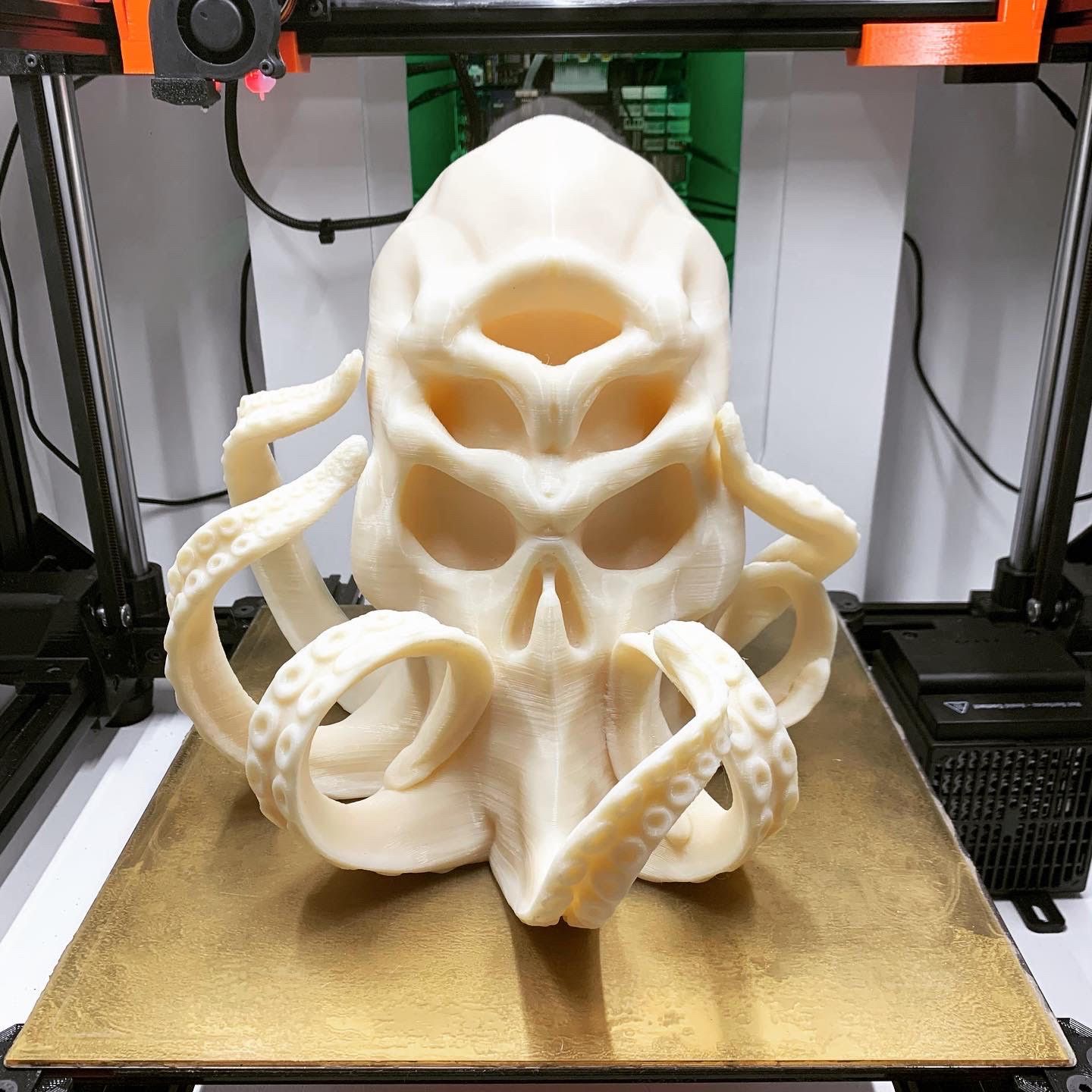

We are using the Slice Magnum in a heated chamber at 70c for ABS. It is air-cooled with no recognizable heat creep. We just recently completed this large scale test in ABS with a 1.2mm nozzle with no supports. Extrusion width was 1.8mm and layer height was .4mm. It is 300mm deep x 264mm wide x 244mm high, was printed in ~17 hours, and weighs right at 3.5lbs.

edit - what I wrote is a bit misleading. Most ABS parts are done with a chamber temp at 70c. Due to the overhangs on this print, we reduced the chamber temp to around 50c.

-

I found the problem, the brass insert failed for the extruder, so the arm wasn't holding tension.

-

@oozeBot

IS that a core xy printer? -

@davidvh86 you can read more about it here:

https://forum.duet3d.com/topic/18485/oozebot-ele-gant

Thanks