leadscrew vs ballscrew

-

@CaLviNx said in leadscrew vs ballscrew:

@arhi said in leadscrew vs ballscrew:

the angle I'm talking about if unclear is the angle between the center axis of the nut and the center axis of the screw

Good design and proper assembly cures all.....

fairly possible when you do it from scratch, not something you can force when you are retrofitting something like wanhao d9

-

@arhi said in leadscrew vs ballscrew:

@CaLviNx said in leadscrew vs ballscrew:

All this says to me is: BAD DESIGN....

as I'm familiar with that build ... it's of course way better design to use single high quality linear rail on each side of the X bar that moves in Z direction, but due to well known situation right now getting a high quality linear rail here is next to impossible and cost more than that whole printer so not really doable. That's why 2 smaller PRC linear rails are used on each side. Doubling them increases their precision / reduces the "play" but increases complexity of the alignment significantly. So the design is driven by what's available and not what's best

... took a while for omni to align those 4 rails and 2 nuts but that machine now works freaking awesome

... took a while for omni to align those 4 rails and 2 nuts but that machine now works freaking awesome  ...

...All my rails come from an Ebay seller in South Korea Dy Global and are either good used or new old stock being Genuine from various manufacturers Hi-Win, THK etc, i usually contact him and just ask for what i want instead of trawling his site as he usually has stuff in stock that is not listed on his page on ebay. I have had 7 orders from him now and every order has been perfect.

He supplies with 72hr shipping via fedex to europe included in the rail price.

So the "excuse" of good rails not being available is horsesh**

The best rails I have had so far are Bosch-Rexroth, they just ooze quality you can see it and feel it from just holding them in your hands

-

@arhi said in leadscrew vs ballscrew:

@CaLviNx said in leadscrew vs ballscrew:

@arhi said in leadscrew vs ballscrew:

fairly possible when you do it from scratch, not something you can force when you are retrofitting something like wanhao d9

For some games that you know you cant win, dont play......

-

@CaLviNx said in leadscrew vs ballscrew:

So the "excuse" of good rails not being available is horsesh**

ah ... don't talk about stuff you can't even imagine

- 99% of amazon sellers will not ship to Serbia at all, no matter what shipping method

- fedex/dhl if/when arrive here cost us another 100eur for "customs processing"

- on top of price+shipping+customs processing we need to pay another 10% customs + another 20% VAT on top of all that

- in order to do "customs processing" we need to show proof that it will not be used in food production, weapons manufacturing and provide bunch other "import" paperwork + if customs decide on we have to pay for testing "quality" of the goods... laws didn't change much from Tito era

and are made for big corporations to do all the import work and for private persons to be able to have access to only local stuff .. we use tricks to go around it but due corona most of those channels are dead now

and are made for big corporations to do all the import work and for private persons to be able to have access to only local stuff .. we use tricks to go around it but due corona most of those channels are dead now

For some games that you know you cant win, dont play......

when you know up front, yes, but when you are already waste deep .. you get it done any way you know how

anyhow, we are hijacking thread with irrelevant discussion

-

@arhi said in leadscrew vs ballscrew:

@CaLviNx said in leadscrew vs ballscrew:

So the "excuse" of good rails not being available is horsesh**

ah ... don't talk about stuff you can't even imagine

- 99% of amazon sellers will not ship to Serbia at all, no matter what shipping method

- fedex/dhl if/when arrive here cost us another 100eur for "customs processing"

- on top of price+shipping+customs processing we need to pay another 10% customs + another 20% VAT on top of all that

- in order to do "customs processing" we need to show proof that it will not be used in food production, weapons manufacturing and provide bunch other "import" paperwork + if customs decide on we have to pay for testing "quality" of the goods... laws didn't change much from Tito era

and are made for big corporations to do all the import work and for private persons to be able to have access to only local stuff .. we use tricks to go around it but due corona most of those channels are dead now

and are made for big corporations to do all the import work and for private persons to be able to have access to only local stuff .. we use tricks to go around it but due corona most of those channels are dead now

Try living on an "island" (Cyprus) that is technically in the EU but you get the age old line "cannot ship to your location" Then with couriers who wouldn't know what a decent days work was if it smacked them in the face.

For example: A Parcel Was picked up from a sender in Austria @ 16:00 Wednesday, it arrived in Larnaca (Via Germany) @ 13:15 on Thursday, but delivery is not scheduled until NEXT Tuesday........ So it can travel over 4000kms in just over 9hrs but the last 25kms it takes to travel from Larnaca to me is going to take over 4 days.....

Then there is DHL you pay more for DHL but DHL cheaps out and hands the parcel over to their "local delivery partner" and DHL's "local delivery partner" here is Cyprus Post Office and Cyprus post office is a funny thing they only have postmen in Four locations on the whole island, Larnaca, Limassol, Nicosia & Phafos in any other area there is NO postmen/woman, what they do is that you have to register your mobile telephone with them and when anything arrives for you, they send you a SMS and you have to go and collect so even if you paid more for DHL you still have to collect it. And as soon as DHL passes the parcel over to Cyprus post office, the tracking lists is as "item sent abroad" and from experience that means it arrives in Cyprus the very same (or next) day but tracking is never actually updated for 2 to 3 (usually 3) weeks saying the item has just arrived, and then once it has been listed as having arrived it usually takes 10 days to actually arrive at the local post office, so a thing you paid for to be sent on a 3 to 5 day service ends up taking over a month, DHL hate me as I make a claim for my cost of shipping EVERY time they do this.

Then we get on to the local mafi.. (sorry customs) they arbitrarily add a certain amount as a "service" charge to release items (even if it came from Europe) as and when they choose.

Then we get to the independent couriers who the likes of TNT and ARAMEX use, well they all deliver your "expedited" (read higher price paid) parcel to their "local office" and then again send you and SMS trying to get you to go and collect it from their local office instead of them actually delivering it to your door, I have an email/sms trail of 37 messages from a local courier company asking me to go and collect differing parcels, and every reply to them I tell them "NO deliver it" and the very next day (or two) they do deliver it, but if you let them get away with it they will try to save money by not doing their job.

Then you get the age old excuse "I cant speak English" to try to avoid doing anything, i either do one of two things, if im with someone i turn to the person im with and insult the person in english, that person who just said they couldnt speak english, if they react, i reply oh I thought you said you couldnt speak english.... if im on my own i reply to them in Greek, as i can speak it quite well.

So yes horsesh** everyone all over the world has their own set of circumstances to overcome, so the line :

"ah ... don't talk about stuff you can't even imagine

"

"Doesn't wash with me.

-

@arhi said in leadscrew vs ballscrew:

................. 10mm screw and 1x2 pitch nut "grabs" more threads ..............

No it doesn't. A four start screw with 8mm lead has a pitch of 2mm which is exactly the same pitch as a single start screw with 2mm lead. The number of threads from peak to peak engaged with a nut is exactly same in both cases.

I'll concede that the helix angle is different though - that might make a difference. But if one cannot align a lead screw that is only constrained at the motor end, within the amout of "float" that any nut will give, then one should not attempt to build a printer, but take up another hobby like knitting perhaps where it wouldn't matter if the socks turned out a bit wonky.

-

@CaLviNx said in leadscrew vs ballscrew:

Try living on an "island" (Cyprus) that is technically in the EU but you get

6 months in 2003 in Nicosia

4 years after that in Lemessos (50m from Castle hotel, next to the go-cart track)Was CTO of PlanetSky :D, was shipping dvb cards from Cyprus to whole EMEA, shipping servers trough EMEA, getting sat eq. to Cyprus ... the pain... I still feel it

It is not as bad as here but yes, you know the pain of "won't ship", I retract the "you can't even imagine"... damn, yes you can ..

... So it can travel over 4000kms in just over 9hrs but the last 25kms it takes to travel from Larnaca to me is going to take over 4 days

I can show you tracking info where stuff arrives to the Belgrade post office in under a week and then it takes 2 months to go through customs and arrive to my home... and that's not a "special case", it's rather "normal" .. it's the reason Aliexpress killed "free shipping" and "cheap shipping" for most stuff to Serbia and only fedex/dhl works now.

-

@deckingman said in leadscrew vs ballscrew:

No it doesn't. A four start screw with 8mm lead has a pitch of 2mm which is exactly the same pitch as a single start screw with 2mm lead. The number of threads from peak to peak engaged with a nut is exactly same in both cases.

nope because the 10mm nut is bigger... I'm not sure how they make them but I suspect it's some relationship between diameter and height so the 10mm nut is higher than 8mm nut but good 30%

I'll concede that the helix angle is different though - that might make a difference.

no idea, maybe that makes difference, as I said it's just observed that the 10x2 handles less angle than 8x4x2 ... I never got too much into reasons, just the fact that nut is longer explains it partially

But if one cannot align a lead screw that is only constrained at the motor end, within the amout of "float" that any nut will give

These nuts don't give at all, the tolerance is crazy tight, but as said, it took a bit of trial and error and 4-5 tries but it was aligned properly and now works awesome. It is just mentioned 'cause compared to 8x4x2 the 10x1x2 was a lot harder to align ... not impossible, just harder ... 8x4x2 took no effort, 10x1x2 took a whole day

-

@arhi said in leadscrew vs ballscrew:

nope because the 10mm nut is bigger... I'm not sure how they make them but I suspect it's some relationship between diameter and height so the 10mm nut is higher than 8mm nut but good 30%

But the OP was comparing the just the lead. His exact comment was (quote)

"Also it's much more difficult when the lead on the leadscrew is 2mm instead of 8mm which is more common on printers since it's much more sensitive to misalignment."

He made no mention of different diameters. That's what I was commenting on. Of course a bigger screw and bigger nut will behave differently but that's not what the OP said.

-

@deckingman said in leadscrew vs ballscrew:

He made no mention of different diameters. That's what I was commenting on. Of course a bigger screw and bigger nut will behave differently but that's not what the OP said.

omni uses bigger screw (10x1x2) and mentioned how harder it was to line up and you replied to his post

.. all clear now

.. all clear now -

@CaLviNx said in leadscrew vs ballscrew:

mind you i have a few years of experience of straightening hydraulic rods offshore.

that might be it!

-

I use two (lightly used) Bosch Rexroth ballscrews (floating bearing one side, angular contact bearings the other side) in conjunction with two (lightly used) IKO LWHT15 linear rails for my Z axis, and couldn't be happier.

Those options aren't cheap though, especially at 900mm long. I think a nice belt driven setup would give you the results you need.

-

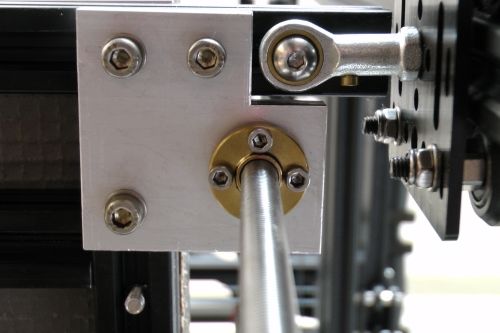

@arhi Regarding the issue you had with alignment, I use the lead screws to level the bed, not just lift it. That is to say, I have no levelling screws - I simply slacken the grub screws holding the pulleys to the lead screw, rotate the screw, then tighten the grub screws. Of course, I turned down a section of the lead screw so that the pulley fits over an unthreaded section. Because of that, I needed to have some "float" so that the nuts don't "bind" before the bed is levelled. So I use an "O" ring between the nut and the block that attaches to the build platform, and longer bolts with Nyloc nuts. The nuts are tightened just enough to start to compress the "O" ring. Here is a picture

And this is the part fitted to the machine

Prior to levelling, the build platform might not be truly at right angles to the lead screws, but this arrangement prevent the nuts from binding because of the "float" allowed by compressing one side or other of the O ring.

-

@deckingman said in leadscrew vs ballscrew:

@arhi Regarding the issue you had with alignment

Not me, I know the machine where the changes were made and I assisted a bit but it's omni who did it all and he finally turned that D9 into next level machine

... I personally never used 10mm leadscrews, I used 8mm "screw", 8mm acme leadscrew in 8x1x2, 8x2x2, 8x4x2 and 8x1x8 configuration and 1605 ballscrew (and some bigger ballscrews but not on 3d printers) so neve tried the 10x1x2 omni used (and he chose those as those were available locally, 8x1x2 he wanted were not available locally... so all the binding experience is his, I only experienced it trough viber

... I personally never used 10mm leadscrews, I used 8mm "screw", 8mm acme leadscrew in 8x1x2, 8x2x2, 8x4x2 and 8x1x8 configuration and 1605 ballscrew (and some bigger ballscrews but not on 3d printers) so neve tried the 10x1x2 omni used (and he chose those as those were available locally, 8x1x2 he wanted were not available locally... so all the binding experience is his, I only experienced it trough viber  trying to help with some ideas and suggestions and printing some parts omni designed while his printer was inoperable... mine machines are lot different design so I never had that type of a problem

trying to help with some ideas and suggestions and printing some parts omni designed while his printer was inoperable... mine machines are lot different design so I never had that type of a problemSo I use an "O" ring between the nut and the block that attaches to the build platform, and longer bolts with Nyloc nuts. The nuts are tightened just enough to start to compress the "O" ring.

that's a nice idea, to solve the angle problem. It would not solve the XY wobble IMHO but that would allow for god variance in an angle so that nut does not bind

good share, thanks

good share, thanks -

@arhi said in leadscrew vs ballscrew:

that's a nice idea, to solve the angle problem. It would not solve the XY wobble IMHO ...........................

Er no - controlling XY wobble is the job of the linear guides, not the lead screws.

-

@deckingman said in leadscrew vs ballscrew:

Er no - controlling XY wobble is the job of the linear guides, not the lead screws.

yes, on proper designs... but I'm around since the beginning and on the old designs (read Darwin) the XY wobble due to bent Z rods was a big deal and different XY "arrests" were made ... none of them very good... finally the designs started to look more like standard cnc machines where all those issues are sorted long time ago

-

well i got some pulley and belt , here a more define version of the pulley box i kept a possibility to had a second motor if 1 is not enough .9 degree stepper with 20>60>20>60

should give plenty of strength and e step as well , if i calculated accurately one set of pulley should give 480 e-step adding the second should be 3x that so 1440 e-step total,him my right ?

-

so only thing i need to do now to complete the conversion is to make some flat on the 5mm shaft so that the pulley doesnt roll on it , and test if that work ,

when i was removing the leadscrew once i unscrew everything it didnt look to be bend has much anymore so i guess the weight of the platform might have been too much for the tiny 8mm leadscrew making it flex on the weight ,

-

here an update did a test cube , side wall was way smoother no Z pattern anymore , bad new is the cheap mosfet i was using for the bed a connector melted , so no bed heater until i get another one , also ordered a ssr relay so i will eventually switch to that , need to print a few more thing to finalized the belt system ,