After Micro swiss DD upgrade,Extruder skips steps

-

@Veti ok

with which one i begin ? retraction Speed,distance ... ?

-

distance

-

@Veti ok

right now i am at:

M98 P"0:/macros/Tuning/Report Current Retraction Settings.g" Tool 0 retract/reprime: length 0.25/0.25mm, speed 35.0/35.0mm/sec, Z hop 0.00m without stringing,is it good ?

-

you have to decide that by yourself if you are happy with the result.

-

it looks great !

but one question why with slicer retraction i have 1.5mm and with firmware retract i have 0.25mm ?

the distance are good ,now i will check with speed right ?

-

yes you can, but 35mm/sec is a good speed for retraction

-

-

i want print the benchy but the first layer adhesion is terrible what i can do now ? before it was all good

-

can you post a picture of the result?

-

I dont have adhesion for the first layer so i dont have printed

Indint know if i calibrate the EM again or z-offset

-

Clean the bed maybe?

-

@Phaedrux allready done with iso....

I will check this

-

Wish I had of caught this post before you went through everything. The MicroSwiss DD can't use a pancake style motor. This is due to the MS DD not being geared. Use a 42-34 Nema 17.

I ran through all the same problems and was immediately fixed by putting the stock motor on, a 42-34.

-

you are right @RyanP

-

@RyanP i have the original one here 42-40

-

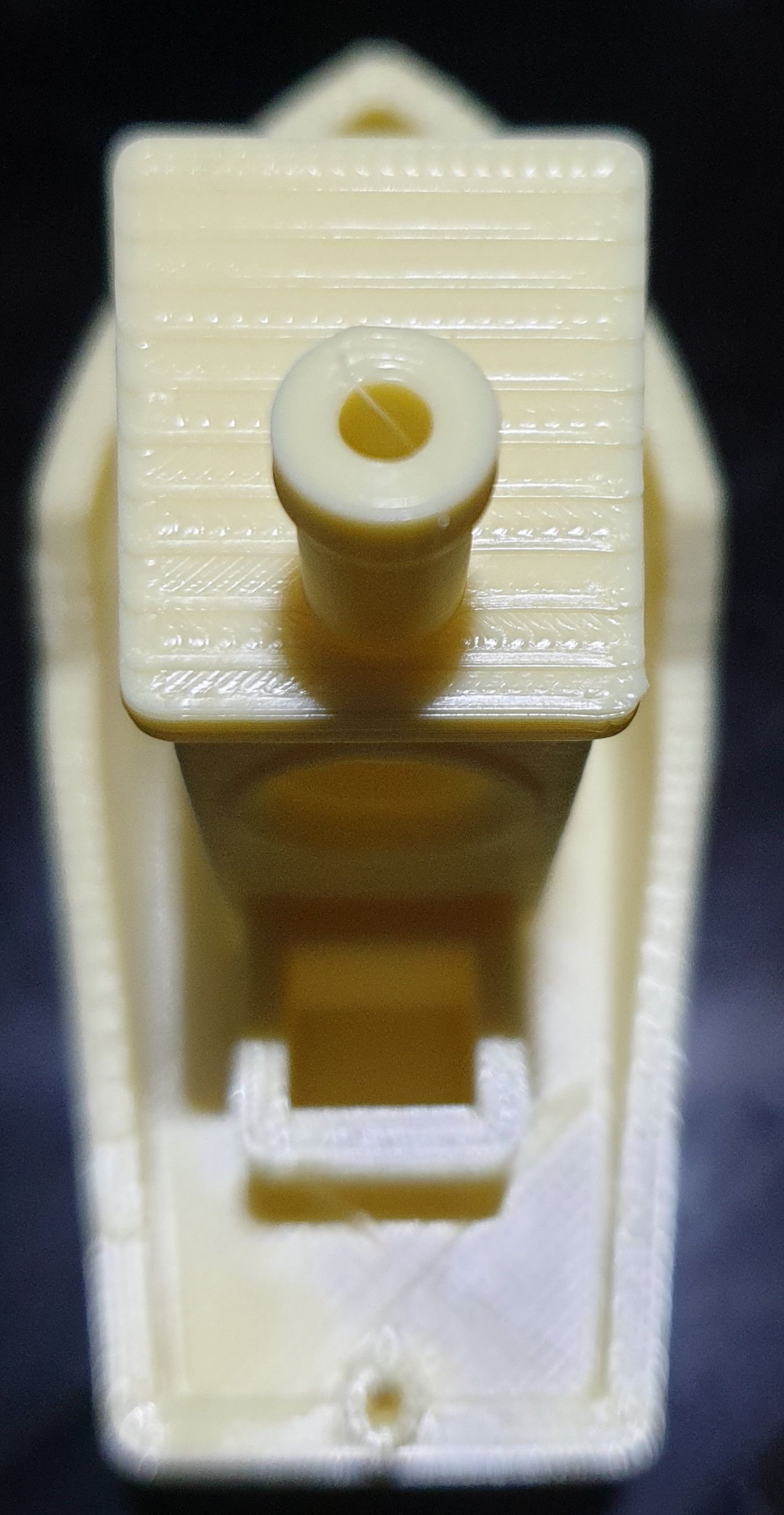

so this my result after frimware retraction setup,if you have somthing to make the print better tell me how

i have printed faster and other widht

my actual config.g

; Configuration file for Duet WiFi (firmware version 1.21) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2 on Tue May 07 2019 23:06:50 GMT+0100 (British Summer Time) ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"Ender 5" ; Set machine name M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Physical drive 0 goes forwards M569 P1 S1 ; Physical drive 1 goes forwards M569 P2 S0 ; Physical drive 2 goes backwards M569 P3 S1 ; Physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.20 Y80.12 Z794.04 E277.89 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E4000.00 ; Set maximum instantaneous speed changes (mm/min) M203 X15000.00 Y15000.00 Z600.00 E8000.00 ; Set maximum speeds (mm/min) M201 X500.00 Y500.00 Z200.00 E8000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1400 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X220 Y220 Z300 S0 ; Set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;Filament Sensors M591 D0 P2 C"!e0_stop" S1 ;Extruder 1(0) M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H3 F60 T6000 A10 R0.75 S0.003 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X41.2 Y4.5 Z2.498 ; set Z probe trigger value, offset and trigger height M557 X41.2:221.2 Y4.5:219.5 S20 ; define mesh grid M671 X28.8:198.8:198:28.8 Y24:24:194:194 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T98801 B4185 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S300 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 S3D ;M563 P0 D0 H1 F0 ; Für Prusa Slicer G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled ; Custom settings are not configured M575 P1 S1 B57600 ; enable support for PanelDue M572 D0 S0.05 ; Pressure Advance M207 P0 S0.25 R0 F2100 T2100 Z0 ; Firmware Retraction M204 P500 T2000 M501 Changed only this the rest are the same as i posted before:

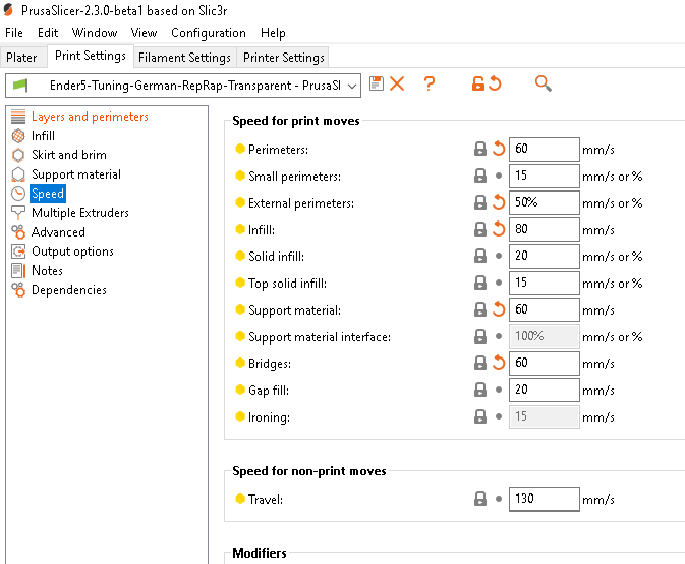

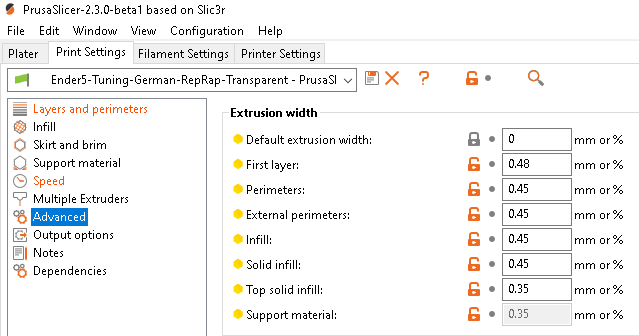

Slicer settings:

Benchy:

-

that look good

-

Looking very good. The benchy hull line is a known artifact, likely due to cooling shrinkage.

-

@Phaedrux ok i will read it.

It can be because i have only 40% partfan because i use Petg.

-

thats a petg print? for that its very good.