After Micro swiss DD upgrade,Extruder skips steps

-

@lui2004

its not uncommon for the 3950 to be off by 20Cdid you change the beta and C value?

-

i have installed the Semitec 104GT-2 today

my config for this :

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 -

thats the thermistor: 104NT-4-R025H42G Semitec Thermistor 100K - NTC

i checked the datasheet and the B Value seems to be: 4267 ?

datasheet:

https://reprapworld.de/datasheets/NTCThermistor_NT-461415.pdf -

@lui2004 said in After Micro swiss DD upgrade,Extruder skips steps:

i checked the datasheet and the B Value seems to be: 4267 ?

B and C change the algorithm to steinhart hart. its more accurate.

see the table

-

the config is also ok like that ?

-

yes, but its still strange that you need 235 to print pla.

do you have a steel nozzle?

-

yes, hardened steel with Micro Swiss all metal hotend

-

@lui2004 ]

ok steel nozzle a very bad for printing pla. the thermal transfer is very low.

unless you are printing abrasive materials, a brass nozzle is a lot better.

or if you want a much better nozzle, there are copper plated nozzles

https://de.aliexpress.com/item/4000007458595.html -

i print only PLA and Petg

-

then there is no need for a steel nozzle

-

Ok i have a cooper plated, i will change now and test it

-

I have changed the nozzle and Calibrated all, all works fine now.

I can print PLA with 200°C! Thanksi have another question i have Bed compensation in use: none is this normal ? i thin it should be mesh or not ?

if you need config.g or slicer start.gcode or anything else tell me i will post it

-

for that your G29 needs to be executed after the G28 in the slicer start code

-

my start.gcode looks like that:

T0 G90 ;absolute positioning M107 ;start with the fan off M83 ; extruder relative mode M104 S[first_layer_temperature] ; set extruder temp M140 S[first_layer_bed_temperature] ; set bed temp ; Homing & leveling G28 M561 ; Clear any bed transform that might be in place G1 X73 Y106 F4000 ; Go to bed center before probing ;Wait for Temperature M109 S[first_layer_temperature] ; wait for extruder temp M190 S[first_layer_bed_temperature] ; wait for bed temp G30 ; Find the Z=0 G29 S1 ; Load the height map from the last time I used G29 to probe the bed. G1 X5 Y10 Z0.2 F3000 ; get ready to prime G92 E0 ; reset extrusion distance G1 X160 E15 F600 ; prime nozzle G1 X180 F5000 ; quick wipe -

this should activate the mesh compensation

do you have a heightmap it can load?

-

yes of course!

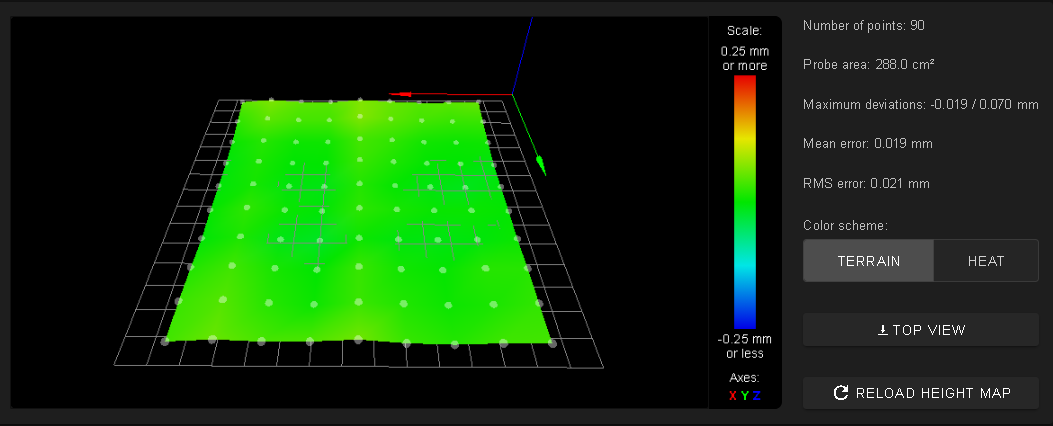

RepRapFirmware height map file v2 generated at 2020-12-15 08:54, min error -0.019, max error 0.070, mean 0.019, deviation 0.021 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 41.20,219.00,15.00,195.00,-1.00,20.00,20.00,9,10 0.055, 0.048, 0.046, 0.056, 0.070, 0.048, 0.050, 0.068, 0.048 0.030, 0.029, 0.036, 0.050, 0.070, 0.037, 0.037, 0.050, 0.024 0.007, 0.005, 0.009, 0.026, 0.037, 0.007, 0.006, 0.020, 0.004 -0.008, -0.001, 0.001, 0.015, 0.031, 0.001, -0.001, 0.014, -0.005 -0.004, -0.014, -0.008, 0.002, 0.019, -0.010, -0.006, 0.011, -0.004 0.002, 0.005, 0.004, 0.012, 0.024, -0.003, 0.005, 0.025, 0.002 0.005, -0.005, -0.009, -0.006, 0.006, -0.019, -0.011, 0.015, -0.003 0.021, 0.020, 0.002, 0.009, 0.030, -0.000, 0.012, 0.034, 0.017 0.027, 0.014, 0.006, 0.017, 0.031, 0.006, 0.020, 0.045, 0.031 0.036, 0.034, 0.019, 0.030, 0.061, 0.041, 0.039, 0.056, 0.035 -

did you check the mesh during the print?

if yes have a look at the generated g code if there is something after the G29 that would invalidate it.

-

during the print it is also Bed compensation in use: none

this a little part from the generated g.code:

; generated by PrusaSlicer 2.3.0-beta2+win64 on 2020-12-15 at 07:58:45 UTC ; ; external perimeters extrusion width = 0.45mm ; perimeters extrusion width = 0.45mm ; infill extrusion width = 0.48mm ; solid infill extrusion width = 0.45mm ; top infill extrusion width = 0.40mm ; first layer extrusion width = 0.40mm M107 ;TYPE:Custom T0 G90 ;absolute positioning M107 ;start with the fan off M83 ; extruder relative mode M104 S205 ; set extruder temp M140 S55 ; set bed temp ; Homing & leveling G28 M561 ; Clear any bed transform that might be in place G1 X73 Y106 F4000 ; Go to bed center before probing ;Wait for Temperature M109 S205 ; wait for extruder temp M190 S55 ; wait for bed temp G30 ; Find the Z=0 G29 S1 ; Load the height map from the last time I used G29 to probe the bed. G1 X5 Y10 Z0.2 F3000 ; get ready to prime G92 E0 ; reset extrusion distance G1 X160 E15 F600 ; prime nozzle G1 X180 F5000 ; quick wipe G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion ; Filament gcode ;LAYER_CHANGE ;Z:0.2 ;HEIGHT:0.2 G10 ; retract G1 Z0.200 F7800.000 G1 X70.563 Y70.965 G11 ; unretract ;TYPE:Skirt G1 F900.000 G1 X71.065 Y70.492 E0.01957 G1 X71.368 Y70.349 E0.00952 G1 X71.629 Y70.293 E0.00756 G1 X148.407 Y70.297 E2.17871 G1 X148.632 Y70.349 E0.00657 G1 X148.935 Y70.492 E0.00951 G1 X149.437 Y70.965 E0.01957 G1 X149.650 Y71.366 E0.01287 G1 X149.707 Y71.629 E0.00764 G1 X149.707 Y148.371 E2.17768 G1 X149.650 Y148.634 E0.00764 G1 X149.437 Y149.035 E0.01287 -

that is strange.

if you issue G29 S1 in the console what does the compensation say?

-