Trianglelab Matrix Extruder somebody?

-

@Chriss said in Trianglelab Matrix Extruder somebody?:

On the other hand seams the copperhead with a bondtech extruder a very promising concept as well.

well you can use the copperhead with the hermera as well.

see toms review of it

https://www.youtube.com/watch?v=1YU6Ehwiu4A -

thinking about the bondtech lgx a bit more.

the weight should be comparable with this

https://de.aliexpress.com/item/4000983379658.html

slap a copperhead on it and you can buy it today. -

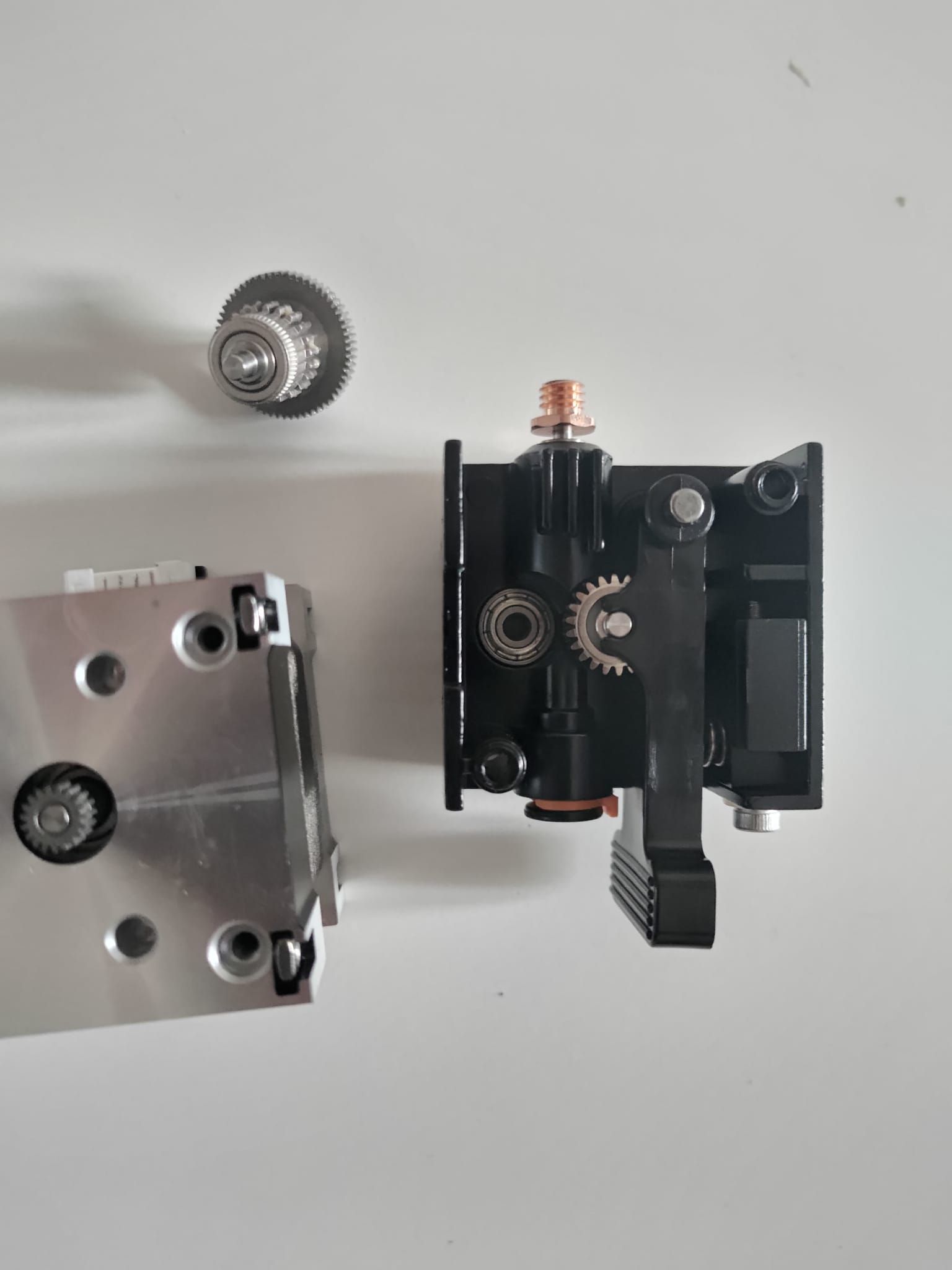

Came today! Quality wise its seems very good. Mostly Metal. Only the Lever is out of Plastic.

I would order a spare heatbreak. Looks very delicate. But its nice to see that its not hold by only a grub screw. They machined a extra inlay for it!

-

By using the surgical stainless tubing at least they have a heatbreak with a very smooth inner wall and low heat transmission. Works very well. I did the same on my homebrewn hotend (but I used some RVS304 M2 threaded rod to support that thin tube), and that one performed better than the Chimera I am running now, especially with flexibles.

That lever looks like it is prone to deform in slightly higher ambient temperatures, but judging based on the pictures it is fairly easy to replicate in metal.

Thanks for the pictures!

(my LC one has not shipped yet) -

Does not look bad, thanks for the pictures. Let's we how the pair I will get look like.

-

-

i dont like how the heater block is held only by the tiny surgical tube .

this tube is press fit bi metal . i have this kind of tube on v6 , also made by trianglelab and i can spin the heater block while holding the cold side . -

In case that's really an issue it is quite easy to add a small bit of silver braze. That's how I connected surgical tubing directly to brass nozzles in my DIY hotend (heatbreak and nozzle were one part in that design).

-

My pair of matrix came yesterday evening. They look like a okish deal to me. The surface of the milled parts do not look very bad but not as good as it could, well the price is the point here.

Funny to see the CN fluctuation here, my pair did not came with nozzles. That is a nobrainer, I have enough of them here but funny to see.

I'm surprised how heavy the complete tool is. I have the feeling that my bondtech head on my corexy is a lot lighter. But I may be wrong, that is just my impression.

-

my bmg wind arrived, and it is very light, as you can use a pancake motor with it.

so far the print results are very good. -

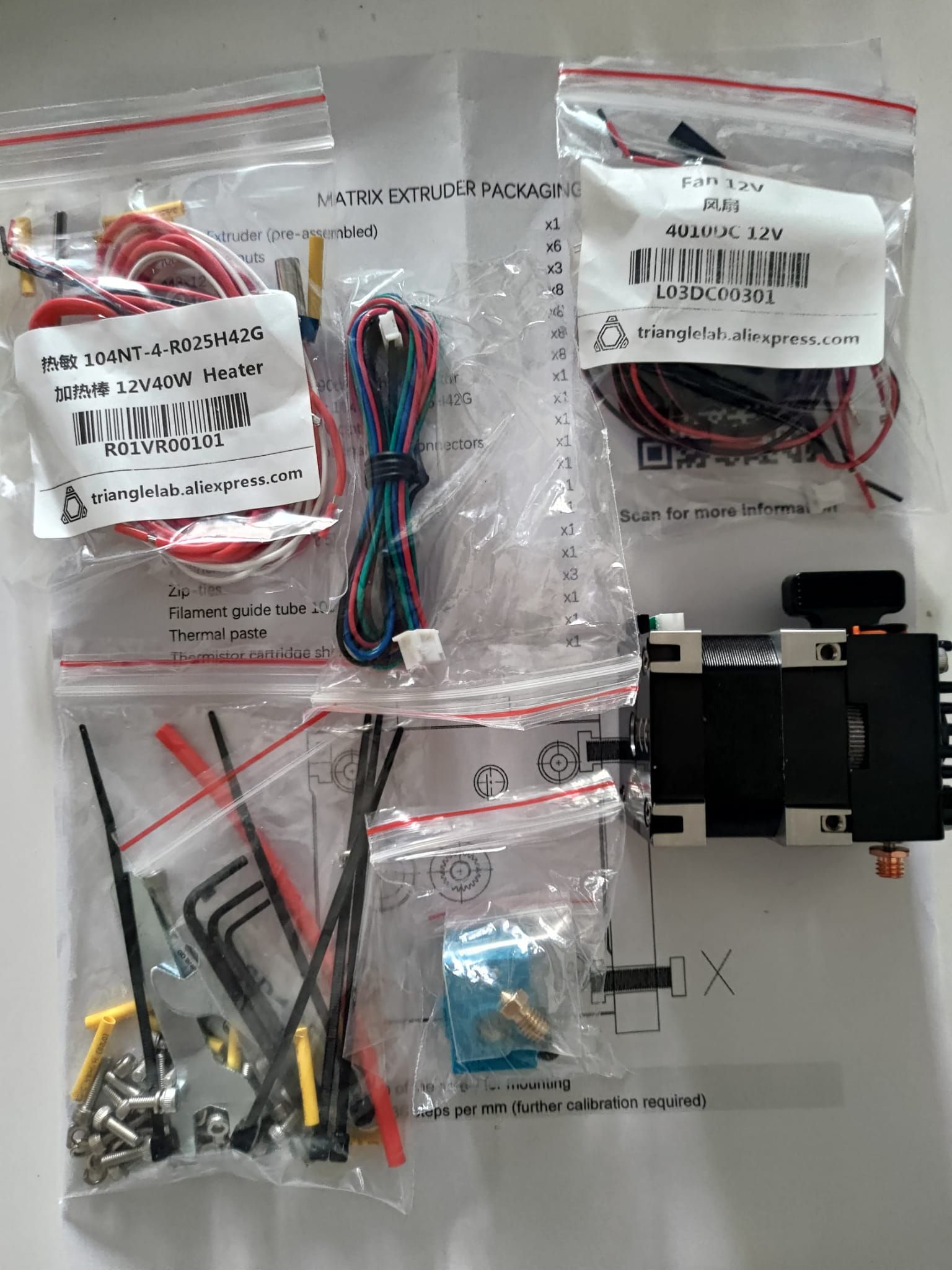

My LC has arrived too.

Package is complete; all cables and things are in:

Looks OK on the outside:

Screw thread for the pillars is M6.

Heatbreak is a one-piece thing, or so it seems (did not pull it out).

3 of the 4 screws hold the aluminium cooling block in place. Guess which one does not

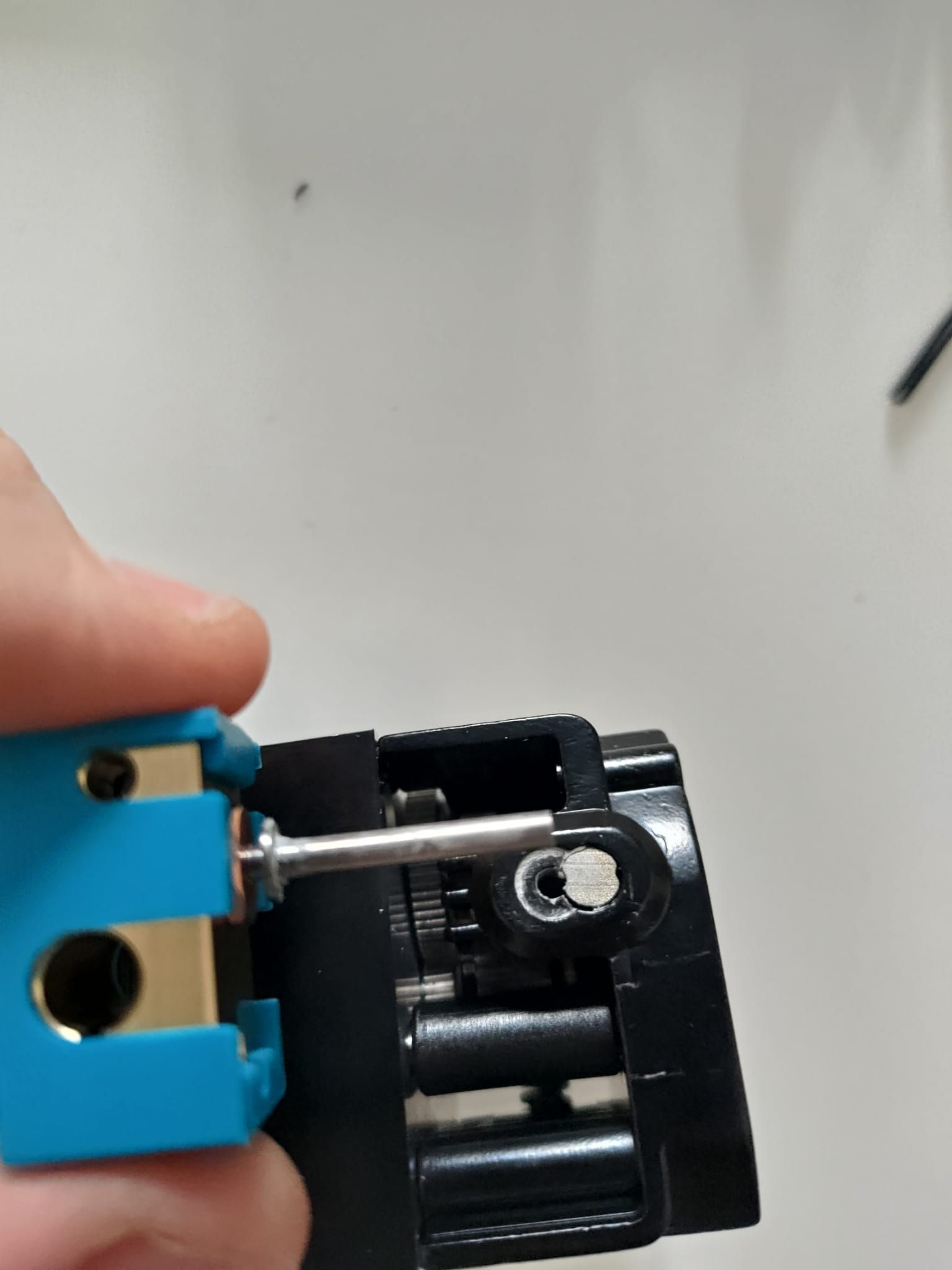

The inside:

Slave drivewheel runs directly in the plastic lever, I don't like that. Bearings are the cheap ones that go crunchy quickly. Oh well, it is built for a price.

Gears are metal, well formed teeth, with neither too little or too much grease applied:

Heatbreak could have been extended a bit more towards the drive wheel:

But oh well, this probably works OK too.

It will take a while before I can actually test it, but the first impression is quite positive.

-

detailed review! Surprisingly well built, but it's still a fair bit of change. Not sure what I'd choose today, but thanks for sharing.

detailed review! Surprisingly well built, but it's still a fair bit of change. Not sure what I'd choose today, but thanks for sharing.Edit: throw it on a scale when you find the time?

-

I am still designing for 150C chamber temperature, and with a bit of extra cooling this thing might be able to handle that just fine. Except for the plastic lever probably.

If it does, it is still a fairly cheap device for such a hostile environment.I will throw it on a scale tomorrow.

-

Totally forgot to put it on the scale, sorry.

Here is the weight:

-

One thing I'd love for you to test, use a metal file and try to file a teet grabbing filament (somewhere on the side, not in the middle where is important. If the teeth are hardened (like on bondtech and some PRC clones) that's awesome and file will not bite and will just slide over them, if the file bites than it's not good for "complex" materials... not a big deal but would be good to know

-

Good test indeed. I will do that when I have it apart again.

(Which I probably will; that plastic handle certainly cannot handle the 150C environment I plan to test, so I want to measure and CADify it.)

I do print carbon-filled filaments from time to time, so if they are not hardened I probably want a set of spare drive gears.

-

@DaBit said in Trianglelab Matrix Extruder somebody?:

carbon-filled filaments from time to time, so if they are not hardened I probably want a set of spare drive gears.

yup, they grind the teeth flat rather quickly if not hardened ... or tbh, they grind the brass teeth quickly, I never tried untreated steel teeth (both original and prc clone bondtech I have are with hardened teeth)

-

Well, those gears are produced from some sort of tool steel anyway since it machines so much better than low-carbon unalloyed steel.

These shaft holders are made from 1.2510 tool steel (with aluminium the shafts would be loose in the holders at 150C, hence steel), hardness as delivered around HRC23. Bores and other features are nice and smooth after machining, even with a simple helical toolpath:

And this is simple hot-rolled steel, same machine, same endmill:

Difference in finish is well visible. Compare that to the picture of the drive gear, so they use at least something similar. Brass would be 1/2 the hardness.

On the other hand I hope they did not make the teeth too hard. That would fracture them over time.

-

Hi *,

Let me come back to the topic.

Does anybody have some infos about the shipped thermistor? (24V)

I have the golden (brass) tube and a spring at the end of the cable. It looks like :

https://de.aliexpress.com/item/33029709571.html?spm=a2g0x.12010612.8148356.14.2b3743aavUups2 but with a spring like https://de.aliexpress.com/item/4000907614466.html?spm=a2g0x.12010612.8148356.2.2b3743aavUups2I'm totally confused now.

Does anybody have some settings which work fine? Is anybody willing to share them and ideally the "M307" for the hotend. I have them connected to a toolboard which can not auto tune the pid.

Cheers, Chriss

-

@Chriss said in Trianglelab Matrix Extruder somebody?:

Does anybody have some infos about the shipped thermistor? (24V)

the thermistor is not 24v. only the heating element is.

they write they ship the thermistor with a Thermistor Semitec 104NT-4-R025H42G.

this is the same as the e3d one.if you connected them to 24v, you will have destroyed the thermistor.