ST3Di Modelsmart 280 - Duet Maestro repair/upgrade

-

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.

That's a good point. It will be run as a lone printer.

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I have an infrared thermometer gun (for the pizza oven). How about in the oven and use that to read the surface temp of it?

that will work for the bed, but for the hotend there will be a temperature difference between the nozzle and the surface.

maybe its possible to replace the thermistor with a known one. thats why i asked for a picture.

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.

yes the problem is that the difference between a semitec 104gt2 and a b3950 setting is more than 20C at 200C

-

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

I have an infrared thermometer gun (for the pizza oven). How about in the oven and use that to read the surface temp of it?

that will work for the bed, but for the hotend there will be a temperature difference between the nozzle and the surface.

maybe its possible to replace the thermistor with a known one. thats why i asked for a picture.

@bearer said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Also as you'll tweak the print profile it doesn't matter if you print at 210 or 215 as long as you get consistent results - i.e. precision is more important than accuracy unless running a print farm.yes the problem is that the difference between a semitec 104gt2 and a b3950 setting is more than 20C at 200C

I'll take the hotend out tonight and see if it can be ID'd.

-

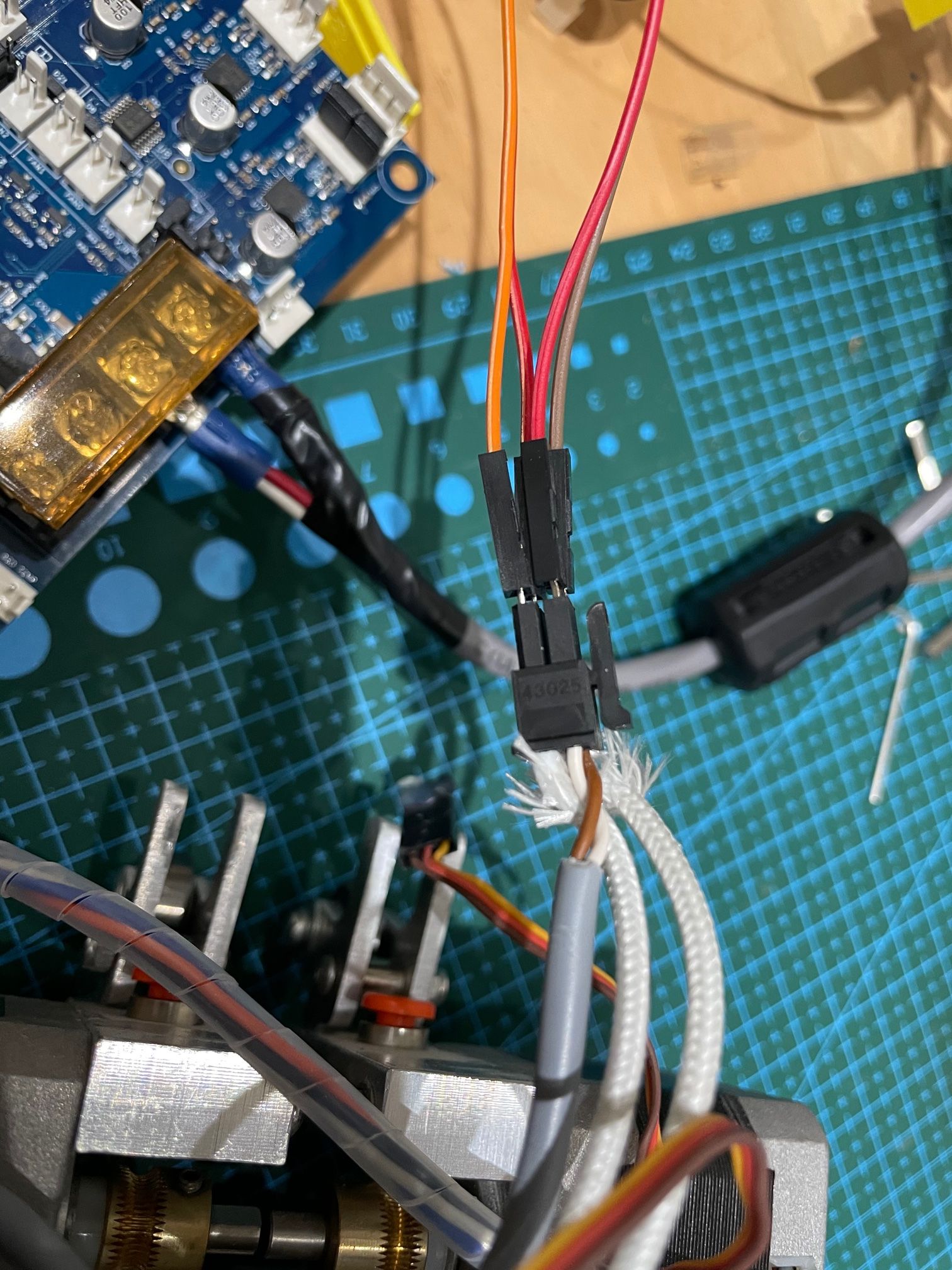

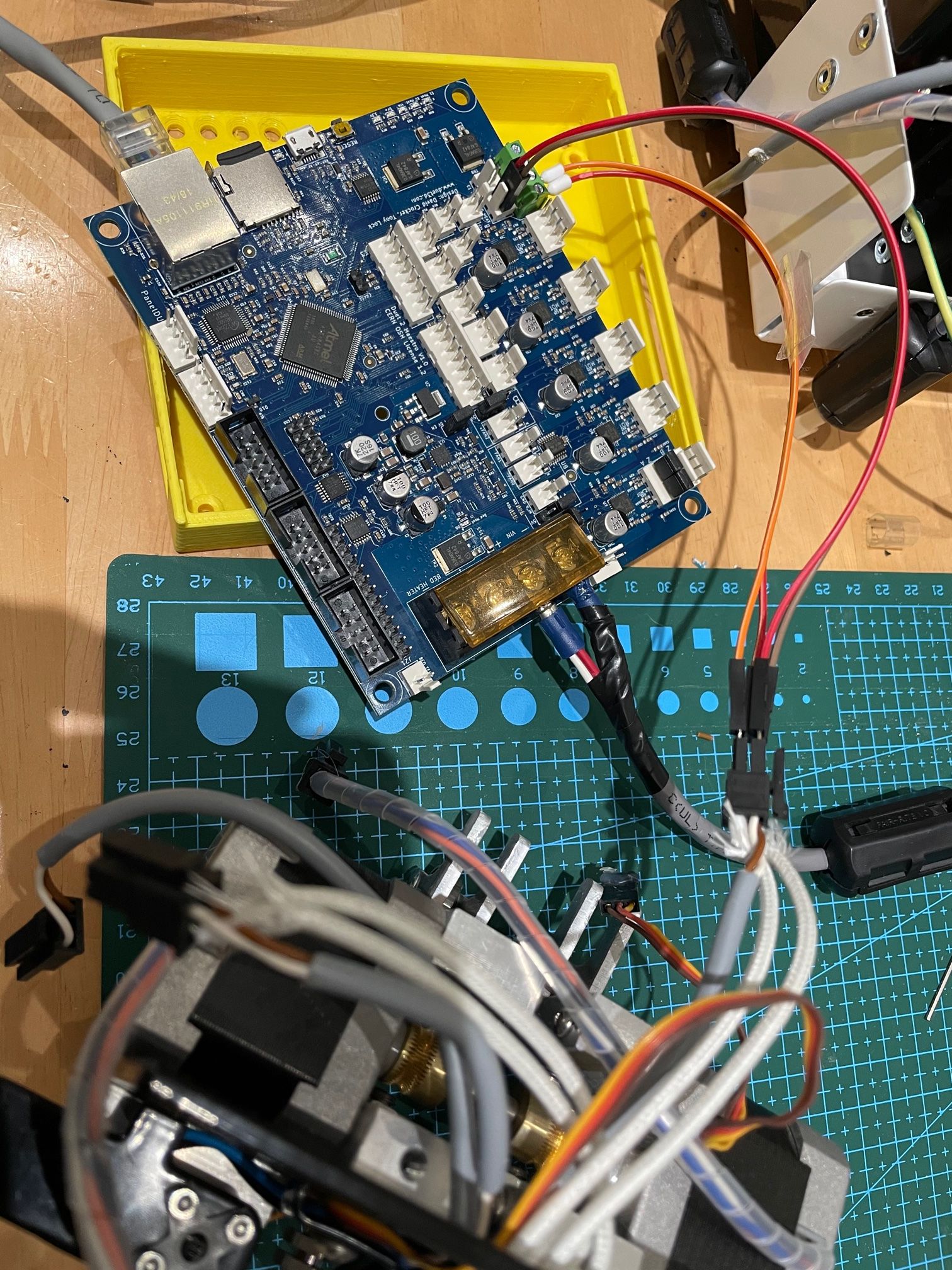

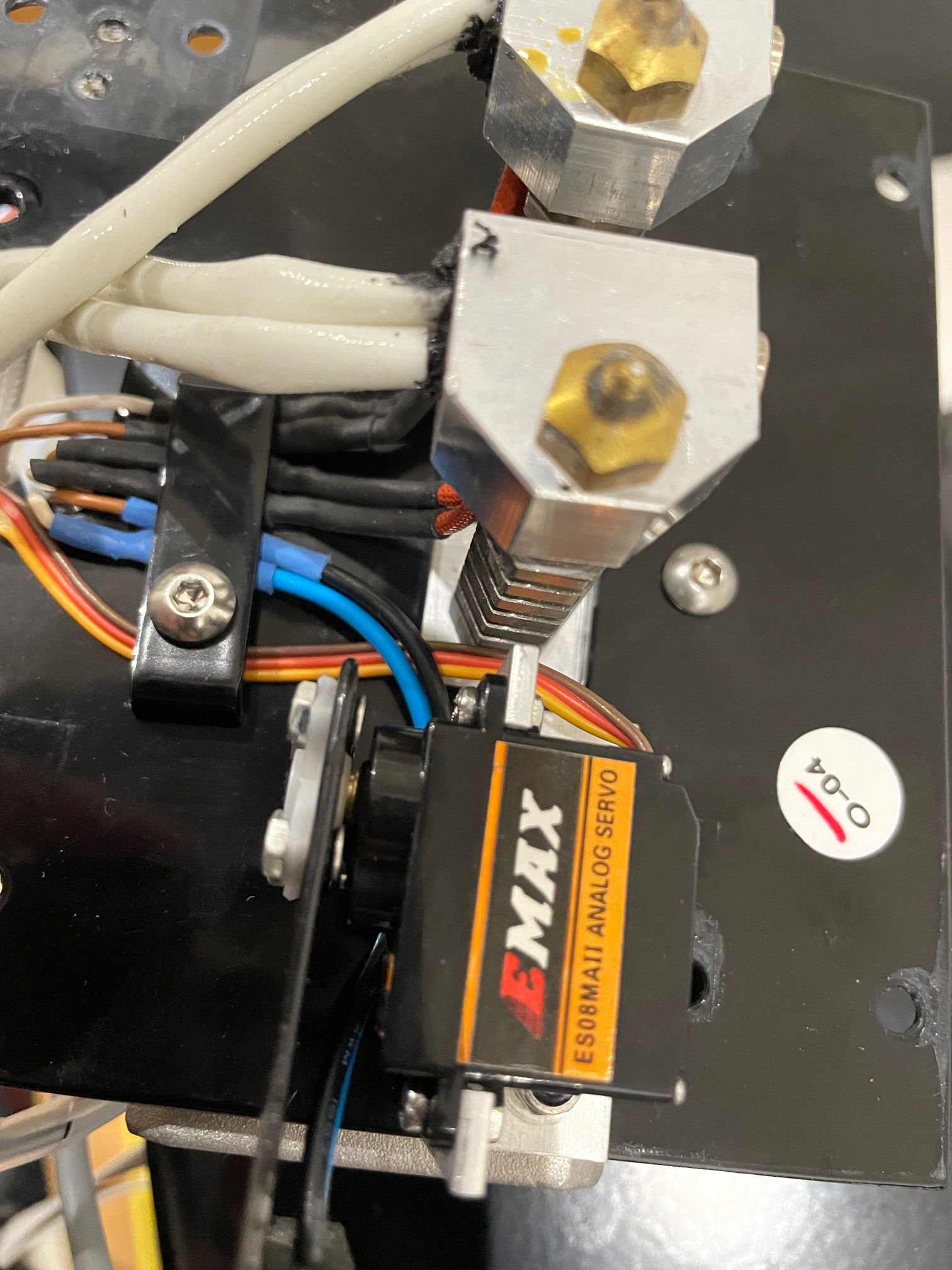

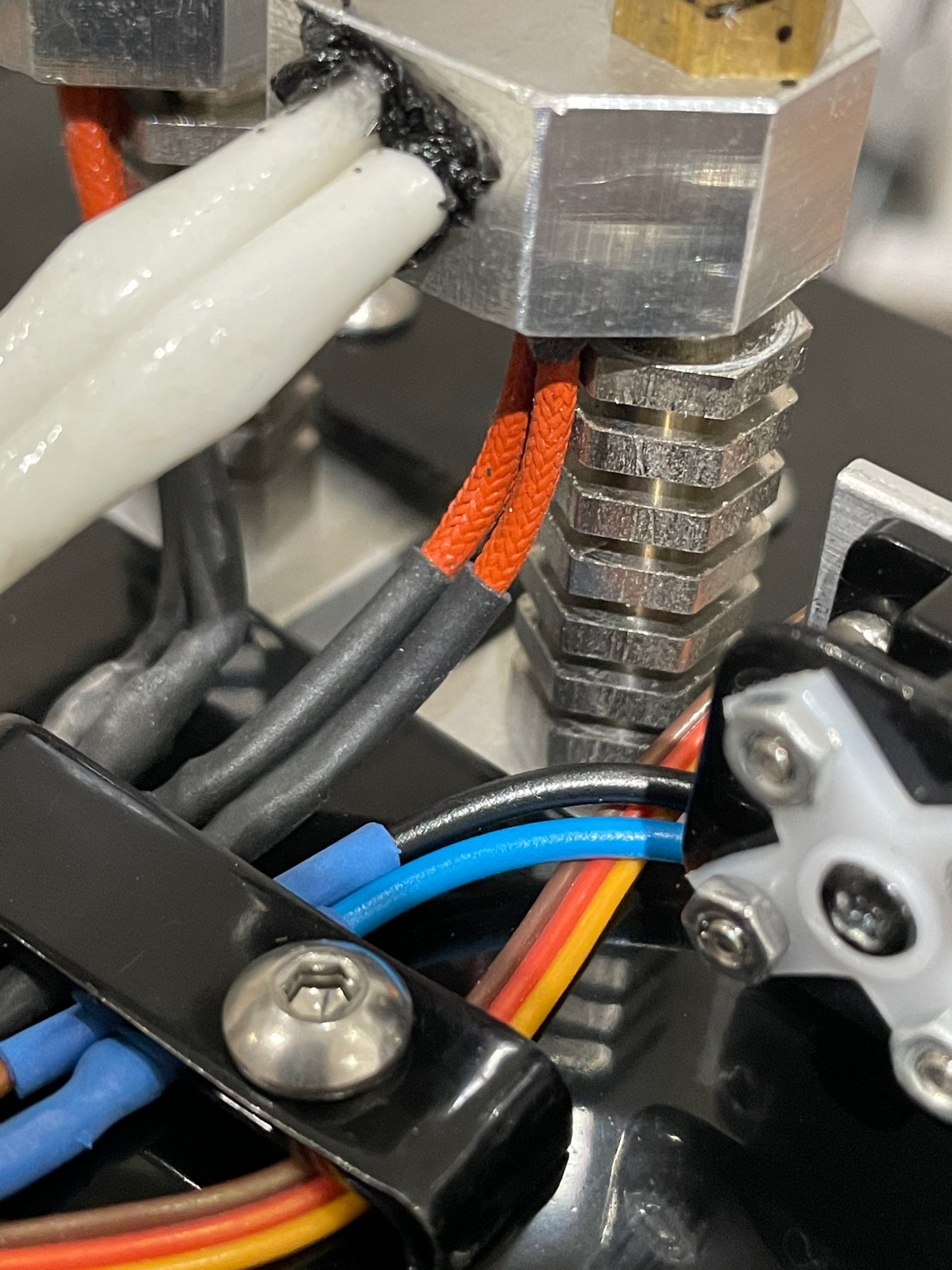

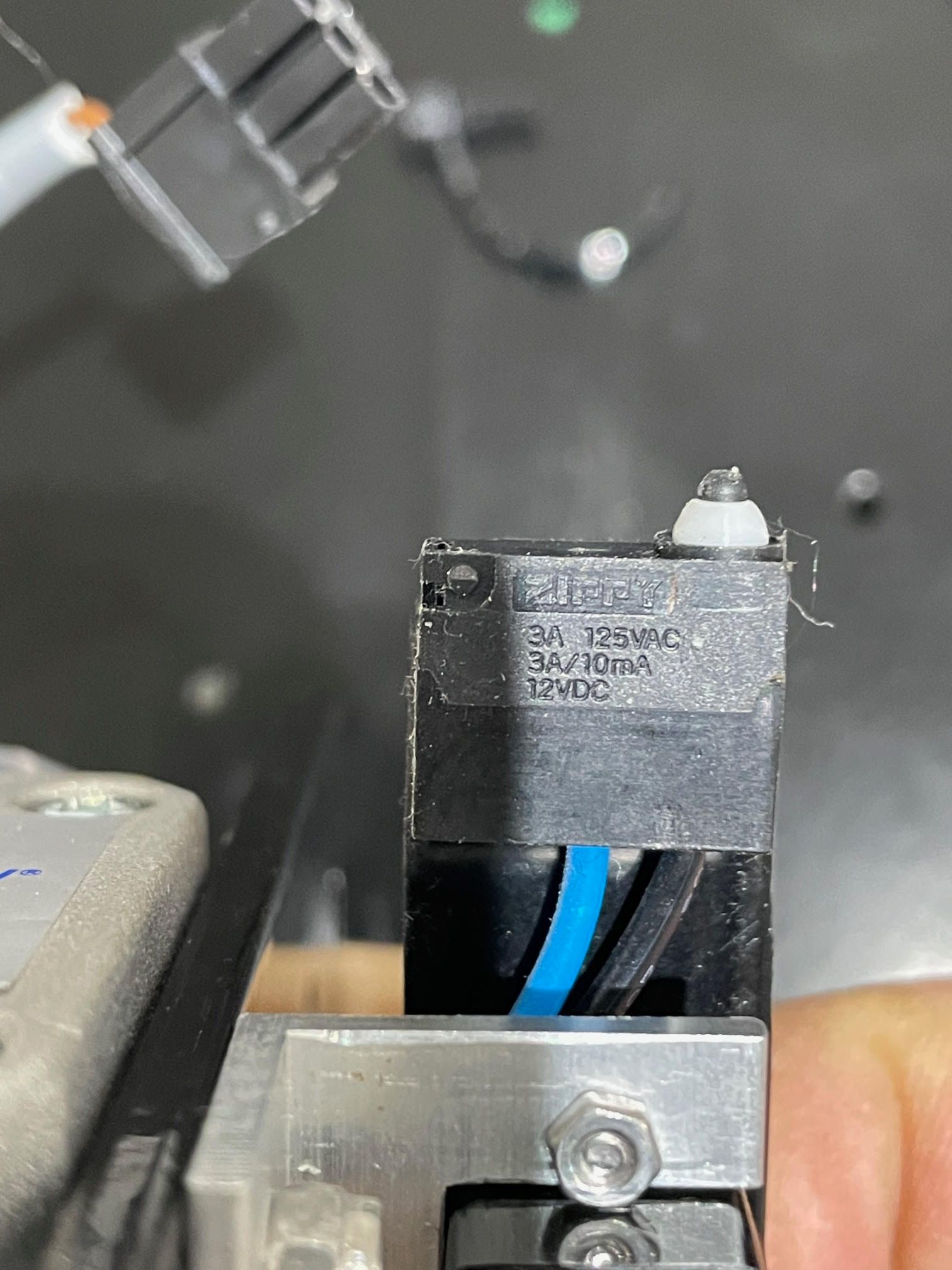

Not sure these help?

-

The endstop/probe. 12v, is that an issue?

-

It could just be a simple microswitch that is rated to handle 12 volts in which case it won't matter if you only use 3.3 volts. You'll need to just use an ohm meter on the wire ends to see if it that style switch. If it only has two wires I would suspect it's just a normal microswitch.

-

@JamesM said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

It could just be a simple microswitch that is rated to handle 12 volts in which case it won't matter if you only use 3.3 volts. You'll need to just use an ohm meter on the wire ends to see if it that style switch. If it only has two wires I would suspect it's just a normal microswitch.

Thanks. I would think/hope you're right.

-

Is the thermistor the white sleeved wirng or the red fiberglass insulated wiring? i'd guess the latter as the heater appears to be a cartridge poking out the other end.

-

@bearer Sorry, it's the red wiring. The white ones are attached to the cartridge.

-

Thats what I thought but the pictures seemed focused on the white wiring, I guess its hard to get a good angle on the thermistor then?

-

@bearer It's not too easy especially with the double print head. I'll try again now. I may take one apart if that would be helpful.

-

If the wires just disappear into some black goo like the heater then i doubt we can identify them visually. But given the construction, a glass bead ntc is the most likely candidate if you want to replace it - but if the mounting is just some sort of adhesive or not idk.

-

Pretty much

-

well you can try your ir thermometer to see if the temperature is close

-

@Veti On the heater block? As in wire up to the board and heat to 220? measure resistance ....

-

sorry i was under the impression you had an ir thermometer

-

@Veti I have one of these

https://www.amazon.co.uk/gp/product/B01AT9TON0/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1

So heat in the oven and then if it measures 220 check resistance. Sorry if I'm been dense

-

unless you have an all metal hotend, go for 200

let it stay at that for a min or so and measure the temperature on the nozzle with the ir thermometer.

-

need to set the correct emissivity for the nozzle to get an reasonably accurate reading, but by the looks of it thats likely to be less accurate then just picking a beta value

-

Small update. I had a bit of time and I wanted to just test a few things. I decided to run the bed heater with the 'default' setting from the config tool. This is what I started with.

code_text ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S80 ; set temperature limit for heater 0 to 80C M308 S1 P"e0temp" Y"thermistor" T137000 B3478 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set temperature limit for heater 1 to 250C M308 S2 P"e1temp" Y"thermistor" T137000 B3478 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S250I ran the autotune for the bed. It gave me this override and I added the M501 to the end of my config

; config-override.g file generated in response to M500 at 2021-01-07 19:46 ; This is a system-generated file - do not edit ; Heater model parameters M307 H0 R0.307 C525.917:525.917 D13.65 S1.00 V24.2 B0 M307 H1 R2.429 C140.000:140.000 D5.50 S1.00 V0.0 B0 M307 H2 R2.429 C140.000:140.000 D5.50 S1.00 V0.0 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 M486 S-1During the bed test and after with my own tests using a IR thermometer gun I was getting within 1-2c of what the Duet was reporting so I was quite pleased to see that.

I disconnected the bed and decided to see what the hotend was reporting. I've removed the hot end part of the carriage from the printer. I connected the heater and sensors to the E0 connections. For these purposes I have used Dupont wires, with bootlace and other supplied connector. Upon starting the board up I got this error.

Error: Temperature reading fault on heater 0: sensor open circuit

I've searched the error and it seems to tell me that there is no connection, there are reports of blown fuses but I don't believe that to be the issue. I have checked for resistance across the connections and it seems there's a connection.

I've now left it as I don't want to do any damage. Any advice on what I need to check? Thanks.

Pics