3D GCode Viewer integrated with DWC

-

Awesome, glad it helped!

-

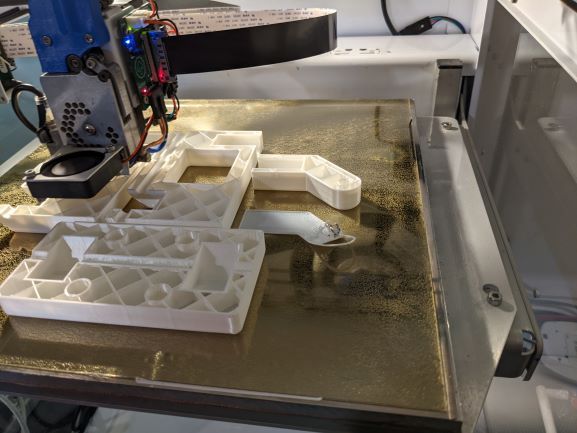

*is printing a multi part file...

One of the parts as apparently on a blob of oil or some nonsense, is going to fail and probably ruin the whole print.

Pause print. Sigh.

Remember that the g-code viewer has a cancel part function.

upload version 3.2 of DWC.

enable Gcode Viewer plugin.

cancel the failing part.RESUME PRINT!

ALL. OF. THE. WINNING.

Like seriously, epic epic feature to have.

-

@theruttmeister said in 3D GCode Viewer integrated with DWC:

upload version 3.2 of DWC.

Mid Print?! Without skipping a beat? Nice.

-

@theruttmeister I have to say that I am impressed with this

-

@Phaedrux said in 3D GCode Viewer integrated with DWC:

@theruttmeister said in 3D GCode Viewer integrated with DWC:

upload version 3.2 of DWC.

Mid Print?! Without skipping a beat? Nice.

Yep.

Just paused, uploaded the zip of the right version of DWC.

Took longer to load the gcode for visualization!

Killer feature!

-

Very nice. Thank you for your work!

What's about displaying some print job infos into the view (for example time estimations)?

-

@MartinNYHC this is something I have been considering for full screen mode. Panels for temperature, position, job status. It’ll probably be beyond a 3.3 release at this moment.

-

@Sindarius said in 3D GCode Viewer integrated with DWC:

@MartinNYHC this is something I have been considering for full screen mode. Panels for temperature, position, job status. It’ll probably be beyond a 3.3 release at this moment.

Very nice!

-

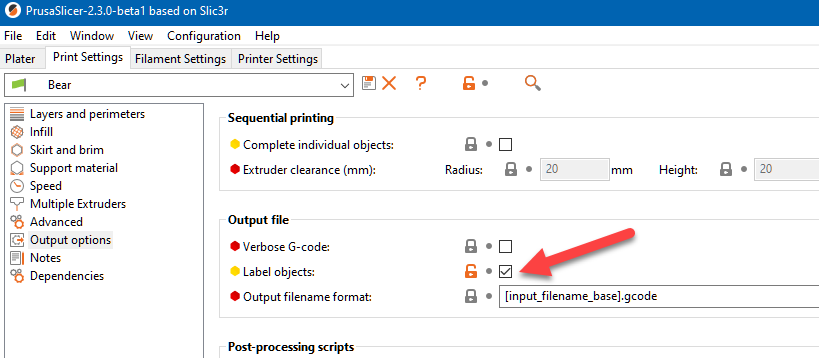

@theruttmeister which slicer are you using? I never got the object Feature to Work!

-

@PCR I personally did my testing with PrusaSlicer. You can enable the feature by checking the Label Objects checkbox.

-

@Sindarius yep tried it. But not worked. Will try it again

-

@Sindarius said in 3D GCode Viewer integrated with DWC:

Added coloring by feed rate.

This is really usefull for Lasers and CNC´s !

-

@Sindarius what would be really helpful is being able to load a gcode for laser use and then jog the nozzle in x and y to ensure the scrap piece of wood you're going to use is in the correct position

-

@jay_s_uk said in 3D GCode Viewer integrated with DWC:

@Sindarius what would be really helpful is being able to load a gcode for laser use and then jog the nozzle in x and y to ensure the scrap piece of wood you're going to use is in the correct position

(

YEP! Also for CNC´s combined with sub-csys (so beside the standard-csys-G54 using sub-csys/"local-csys" like G55 and so on)

-> I think he is aware of it

)BUT -> HEY HEY HEY, do you mean: AFTER the printer was homed -> THERE COULD BE A LIVE VIEW WITHIN THAT PLUGIN OF THE TOOL BY FETCHIN THE CURRENT TOOL POSITION FROM TEH OBJECT MODEL?

WOOAAAAAAAAHHHHHHHHHHHHHH

-

@LB I am looking at displaying each csys with an axes indicator and label at some point soon. I need to look at the code because I believe I am currently using machine position to drive the cursor.

-

@LB Feed rate has a lot of perks including being useful for looking at your movement. In line rendering mode it can help provide a nice color contrast on single material prints.

-

@PCR said in 3D GCode Viewer integrated with DWC:

@theruttmeister which slicer are you using? I never got the object Feature to Work!

Cura 4.4.0 iirc.

Not seen a 'label objects option' but then not ever looked for one. Not looked at the gcode either.

-

@Sindarius said in 3D GCode Viewer integrated with DWC:

@LB I am looking at displaying each csys with an axes indicator and label at some point soon. I need to look at the code because I believe I am currently using machine position to drive the cursor.

I understand. To not confuse people with more and more options (variables, conditions, etc.) it would be cool if it is consitet with DWC and PanelDue of course - I guess that is what you meant?

Cheers

-

Any chance this could be adapted for CNC milling,so instead of adding material, it works on removing material

-

@Sp00kie13 at this point it is just going to show the lines. To show actual carving is a different process. Most viewers I am aware of use voxels and remove them as they are traveled through. The other thing is without endmill information it would be inaccurate. Maybe some day it will be a project I work on but probably not anytime soon.