Resonance, spreadCycle and stealthChop

-

@deckingman I'm clueless, I really tried everything I could and wasted dozens of spools of filament to reprint parts.... corexy is not for me. But yeah mine is (was) a lightweight compared to yours.

Do you have a duet3 or duet2? Could it be the drivers?

-

@matt3o Can you post a video/photo of how you now have your belts configured? I'm still trying to work out what you have changed to!

-

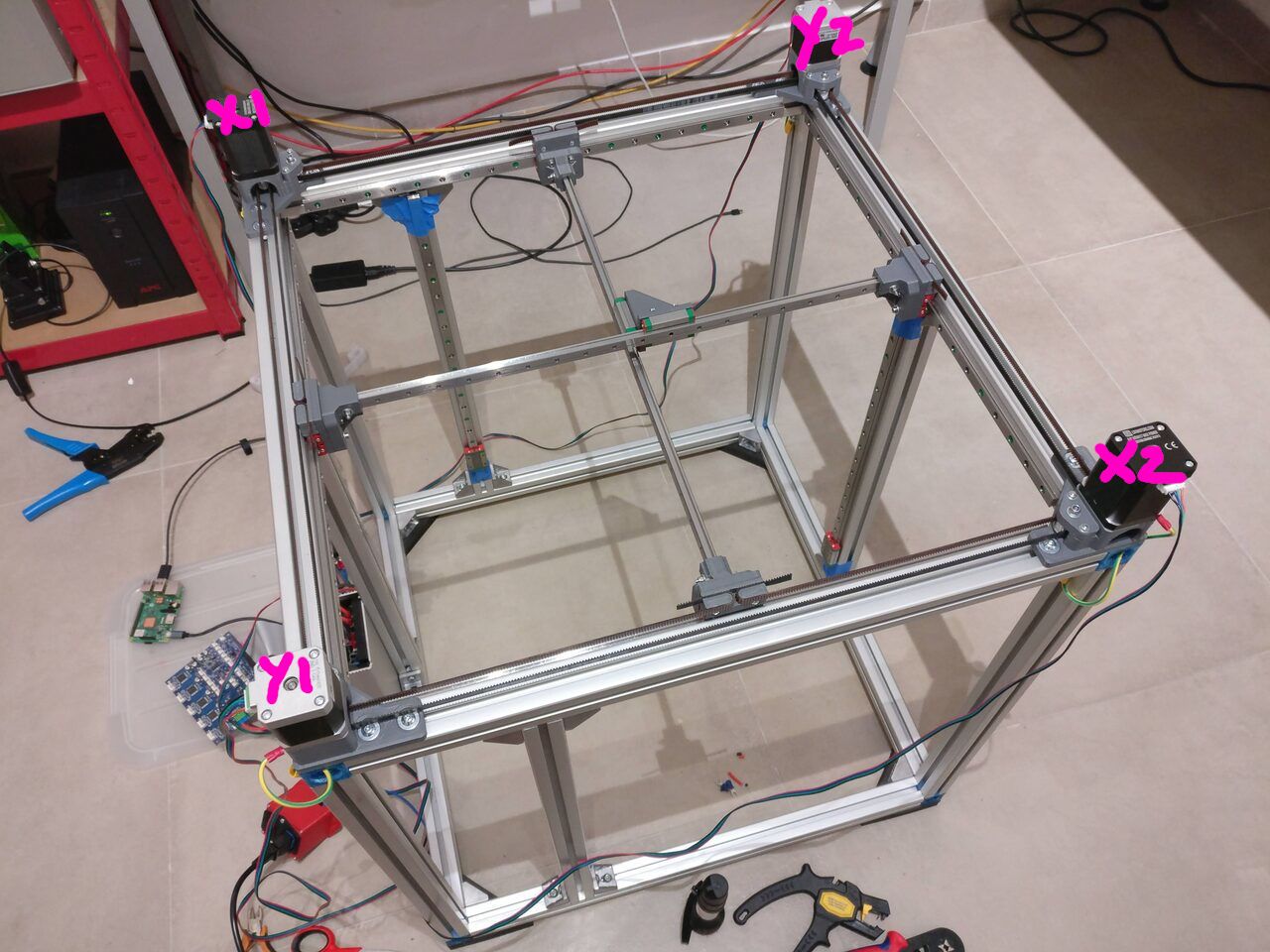

2 motors for X, 2 motors for Y. Simple cartesian in a box

The rails and the frame need to be super square or the gantries will grind. It's a very simple configuration at the end but it needs a lot of motors and a lot of rails.

-

Did your previous corexy setup have 4 motors?

-

@gloomyandy said in Resonance, spreadCycle and stealthChop:

Did your previous corexy setup have 4 motors?

no, it was a simple corexy with 2 motors for XY, but I noticed that resonance happened only when both motors were moving so I switched to this configuration where X and Y are independent.

-

@matt3o said in Resonance, spreadCycle and stealthChop:

@deckingman I'm clueless, I really tried everything I could and wasted dozens of spools of filament to reprint parts.... corexy is not for me. But yeah mine is (was) a lightweight compared to yours.

Do you have a duet3 or duet2? Could it be the drivers?

Mine is currently Duet 3 (Single 6HC main board and three 3HC expansion boards) Prior to that it was a Duet gen 2 Ethernet with Duex 5 expansion board. How about you? - I don't think you mentioned what board or firmware you are using.

Unlikely to be a driver issue I'd have thought, because you'd still have issues after changing the kinematics.

I'd be happy to look over the config.g file to see if I can spot anything which might have contributed to the problem.

-

@deckingman said in Resonance, spreadCycle and stealthChop:

Mine is currently Duet 3 (Single 6HC main board and three 3HC expansion boards) Prior to that it was a Duet gen 2 Ethernet with Duex 5 expansion board. How about you?

I was on the duet3 but I have a duet2 laying around and I'm experimenting with that. The toolboard gave me enough headache.

@deckingman said in Resonance, spreadCycle and stealthChop:

'd be happy to look over the config.g file to see if I can spot anything which might have contributed to the problem.

sure, I really appreciate your help! I made a lot of tests with currents and speeds but I believe the following is the latest version I used.

; _ _ ; ___ ___ ___ ___ ___ _| | |___ ; | _| . | _| -_|- _| | | | . | ; |___|___|_| |___|___|_|_|_|_|_| ; ; Duet 3 Configuration file ; ; General preferences ; -------------------------------------------------- G90 ; send absolute coordinates... M83 ; ... but relative extruder moves M550 P"corezilla" ; set printer name M669 K1 ; select CoreXY mode ; Drives ; -------------------------------------------------- M569 P0.0 S0 ; XY 1 M569 P0.1 S0 ; XY 2 M569 P0.2 S0 ; Z 1 M569 P0.3 S0 ; Z 2 M569 P0.4 S0 ; Z 3 M569 P20.0 S1 ; 1st Extruder on toolboard M584 X0.0 Y0.1 Z0.2:0.3:0.4 E20.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z1600.00 E695.00 ; set steps per mm M906 X1360 Y1360 Z1300 E350 I60 ; set motor currents (mA) and motor idle factor M84 S30 ; Set idle timeout M566 X300.00 Y300.00 Z15.00 E120.00 ; set maximum instantaneous speed changes (jerk) (mm/min) M203 X11400.00 Y11400.00 Z600.00 E2400.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z20.00 E600.00 ; set accelerations (mm/s^2) M593 F45 ; Dynamic Acceleration Adjustment ; Axis Limits ; -------------------------------------------------- M208 X0 Y0 Z0 S1 ; set axis minima M208 X392 Y410 Z360 S0 ; set axis maxima ; Leadscrews location M671 X23.7:218.7:413.7 Y401.0:61.0:401.0 S20 ; Endstops M574 X1 S3 ; configure sensorless endstop for low end on X M574 Y1 S3 ; configure sensorless endstop for low end on Y M915 P0:1 S0 R0 F0 H400 ; configure stall detection; Sensitivity 0, don’t take action, don’t filter, 400steps/sec ; Z-Probe ; -------------------------------------------------- M558 P8 C"^20.io0.in" H20 F120 T6000 ; set Z probe type to switch and the dive height + speeds G31 P500 X0 Y0 Z23.4 ; set Z probe trigger value, offset and trigger height M557 X20:370 Y20:370 S50 ; define mesh grid ; Heaters ; -------------------------------------------------- ; bed M308 S0 P"temp1" Y"thermistor" T100000 B3950 H-10 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 Q10 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit ;M307 H0 R0.729 C638.9 D4.16 S1.00 ; PID tuning M307 H0 R0.600 C700 D6 S1.00 ; PID tuning (manual) M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for bed heater ; 1st tool ;M308 S1 P"20.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin 1.temp0 (E3D) M308 S1 P"20.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 H-13 ; configure sensor 1 as thermistor on pin 1.temp0 (Slice) M950 H1 C"20.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H1 R2.9 C204.0 D4.00 S1.00 V24 ; PID tuning (manual) M143 H1 S320 ; set temperature limit for hotend ; Fans ; -------------------------------------------------- M950 F0 C"20.out1" Q500 ; create fan 0 on toolboard out1 M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"20.out2" Q500 ; create fan 1 on toolboard out2 M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools ; -------------------------------------------------- M563 P0 S"bondtech" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M572 D0 S0.035 ; pressure advance ; Closing ; -------------------------------------------------- T0 ; select tool -

@matt3o Nothing much leaps out at me from your config.g file. I note that you are using DAA (M593). Never had the need to use it myself - what happens if you take it out? Better/same/worse?

The motor currents look low if your motors are 2Amps but I seem to recall that you'd played around with different settings.

Unrelated to your resonance problem but your instantaneous speed change threshold (jerk) settings are low. That's likely to slow down segmented arc moves. (I use 900 as opposed to your 300). Your extruder jerk at 120 will play havoc with pressure advance if you start using that. Suggest you set it really high so that it can't interfere with print speeds (I use 3600).

Sorry that I can't be much more help with your vibration issues.

-

@deckingman thanks for your feedback, really appreciate all your help. I played with currents/speed/accel/jerk. I tried anything I could including DAA. Nothing really helps. Only setting amperage incredibly low (below 1A) somehow mitigates the problem.

Regarding the extruder, thanks for the heads up... I wish I was already optimizing the extruder

-

@matt3o Probably a bit late now, but I wonder if changing micro stepping to (say) 32x or 64X would have had any effect. Strange that reducing motor currents helped .......

-

@deckingman said in Resonance, spreadCycle and stealthChop:

@matt3o Probably a bit late now, but I wonder if changing micro stepping to (say) 32x or 64X would have had any effect. Strange that reducing motor currents helped .......

tried that too from 1 to 256 microstepping. with/out interpolation. nope.

-

Have you try to tackle the mechanical resonance problem by mechanical means? This is something that good mechanical engineers should know how to do.

Here is a demonstration of mechanical resonance, there are no explicit 'pulses' or 'steps' but it resonates never the less.

-

Try the motors, its worth a shot. What you showed in the video its very similar to how the Toolchanger behaved a certain speeds. The frame itself isn't a source of vibration, it can only resonate. For my case its clear the motors are adding the vibration to the system.

StealthChop is another way to prove its the motors/drivers adding the noise. Maybe it wouldn't achieve your performance goals but it would be a good data point to show that the mechanical system can indeed be quiet.

-

@garethky said in Resonance, spreadCycle and stealthChop:

StealthChop is another way to prove its the motors/drivers adding the noise. Maybe it wouldn't achieve your performance goals but it would be a good data point to show that the mechanical system can indeed be quiet.

oh yeah stealthchop is completely quiet, but I start dropping steps at 120mm/s which is lower than a standard travel speed. I'll give the motors a shot... I spent already a fortune on this thing

-

on your corexy design , did you test the motion system before connecting the belts ?

maybe the rails are not 100% parallel .on your cartesian design , i'm not sure if its a good idea to run the rails unsupported like that .

-

@hackinistrator said in Resonance, spreadCycle and stealthChop:

on your corexy design , did you test the motion system before connecting the belts ?

maybe the rails are not 100% parallel .ooooh yeah it took forever to align those rails

in the new motion system I have even more rails. I'm becoming an export at aligning rails!

in the new motion system I have even more rails. I'm becoming an export at aligning rails!@hackinistrator said in Resonance, spreadCycle and stealthChop:

on your cartesian design , i'm not sure if its a good idea to run the rails unsupported like that .

I dunno, they are pretty hefty rails. I hope they will be fine. If it doesn't work I'll put them on a baker.

-

this is funny because on my config (core XY tmc2209 all metal frame and parts) i had to force the spreadcycle because stealthchop was noisy at more than 60mm/sec

and what i think is that stealhchop induce some counter force to reduce the sound (and so on a move you don't have a really perfect sinus wave on your motors wires) but the problem is taht they mess together when using a core XY, because both the variations from each motors arrives in the x cage and from my observations this is from the sound comes. for me the stealthchop mess with itself because it's not supposed to work on core XY. and that's why you got wierd noise when moving both motors at the same time and not on diagonals.

and i have to admit i can live woth spread cycle because honnestly the fans are louder, by far.oh and on the BLV mgn FB page when io talk about my problem the first thing people said was "disable stealthchop, it suxx with marlin" as they thought i was on marlin.

-

that's interesting. just a note though

@psychotik2k3 said in Resonance, spreadCycle and stealthChop:

and i have to admit i can live woth spread cycle because honnestly the fans are louder, by far.

it's not a noise issue. everything shakes!

but anyway with the new kinematics I solved the issue. Don't tell @dc42 but I also installed klipper on the duetwifi

but anyway with the new kinematics I solved the issue. Don't tell @dc42 but I also installed klipper on the duetwifi

-

@matt3o said in Resonance, spreadCycle and stealthChop:

I also installed klipper on the duetwifi

How does this work, did you replace the Duet's firmware with a dumb version that is controlled by the Klipper SBC?

-

@zapta said in Resonance, spreadCycle and stealthChop:

How does this work, did you replace the Duet's firmware with a dumb version that is controlled by the Klipper SBC?

yes, you have to replace the original firmware with Klipper's. I like RRF "all is Gcode" philosophy, but over all I prefer klipper and I don't think I'll revert back, at least for now.