DWC 3.1.1

-

@luca-Massimiliano yes, change lines starting G10 P0 to G10 P1, and G10 P1 to G10 P2.

Ian

-

VORREI FARE UNA PROVA DI STAMPA IN ABS E' CORRETTO

HO UNA DIFFICOLTA' SUL FILAMENO :

CONFIG.G

HO COPIATO DAL MANUALE L ESEMPIO E COPIATO ,

M207 S0.9 R0.0 F3000 T3000 Z0.0 ; firmware retraction settings for PETG

M307 H0 A214.3 C641.7 D1.3 S1.00 V24.0 B0 ; Bed PID tune for 120c

M307 H1 A491.0 C190.9 D2.8 S1.00 V23.9 B0 ; Hot end PID tune at 280c

M566 X1200 Y1200 Z60 E3000 ; jerk settings for PETG

M204 P1000 T4000

Carica macro,:

M291 P"Please wait while the nozzle is being heated up" R"Loading ABS" T5 ; Display message

G10 S200 ; Set current tool temperature to 200C

M116 ; Wait for the temperatures to be reached

M291 P"Feeding filament..." R"Loading ABS" T5 ; Display new message

M83 ; Extruder to relative mode

G1 E10 F600 ; Feed 10mm of filament at 600mm/min

G1 E470 F3000 ; Feed 470mm of filament at 3000mm/min

G1 E20 F300 ; Feed 20mm of filament at 300mm/min

G4 P1000 ; Wait one second

G1 E-10 F1800 ; Retract 10mm of filament at 1800mm/min

M400 ; Wait for moves to complete

M292 ; Hide the message

G10 S0 ; Turn off the heater again

SCARICARE macro,:

M291 P"Please wait while the nozzle is being heated up" R"Unloading ABS" T5 ; Display message

G10 S100 ; Heat up the current tool to 100C

M116 ; Wait for the temperatures to be reached

M291 P"Retracting filament..." R"Unloading ABS" T5 ; Display another message

G1 E-20 F300 ; Retract 20mm of filament at 300mm/min

G1 E-480 F3000 ; Retract 480mm of filament at 3000mm/min

M400 ; Wait for the moves to finish

M292 ; Hide the message again

M84 E0:1 ; Turn off extruder drives 1 and 2HO COPIATO DAL MANUALE L ESEMPIO E COPIATO ,

-

This post is deleted! -

-

This post is deleted! -

https://duet3d.dozuki.com/Wiki/Duet_Web_Control_v2_and_v3_(DWC)_Manual#Section_Jobs

The JOBS tab on the left side bar will show you all the gcode files.

-

E' PARTITA SPERIAMO

-

MI POTRESTI CONSIGLIARE QUALE web camera USARE ACQUISTARE PER ABBINARE ALLA STAMPENTE ?

-

There are many webcams to choose from. The important thing is that the cam can output a image URL rather than just a video feed.

I use a Raspberry Pi Zero W and a Pi cam module with MotionOS.

-

ciao Phaedrux ho ventola una e ventola 2 correttamente sulla scheda , comportamento da me chiesto al raggiungimento a 100 gradi del riscaldatore on . comportamento : ventola 1 al raggiungere 100 ok ventola 2 sempre on ecco config g riguardante

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4388 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"e1temp" Y"thermistor" T100000 B4388 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1 T100 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H2 T100 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"1" D0 H1 F-1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P1 S"2" D0 H2 F-1 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C -

@luca-Massimiliano said in DWC 3.1.1:

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1 T100 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H2 T100 ; set fan 1 value. Thermostatic control is turned onFan1 and Fan2 or do you mean Fan0 and Fan1?

-

Fan1 and Fan2 or do you mean Fan0 and Fan1?

ho capito ,hai ragione diventa :

; Fans

M950 F2 C"fan2" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P2 S2 H2 T100 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T100 ; set fan 1 value. Thermostatic control is turned on -

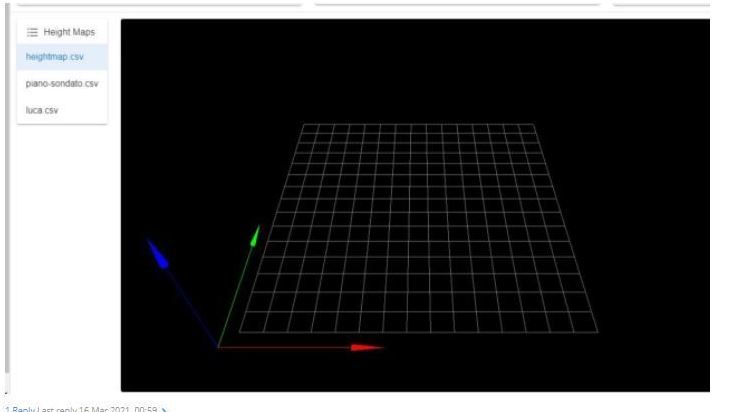

io ho una delta kossel piano cerchio e diverse x y dove posso modificare il dvwc per avere una rappresentazione realistica? graze

io ho una delta kossel piano cerchio e diverse x y dove posso modificare il dvwc per avere una rappresentazione realistica? graze -

This post is deleted!