Smart Effector including toolboard-capabilities?

-

I'm currently dealing with the same issue regarding the filament path right after the BMG gears in my version (the path before the BMG gears is not as critical, I'll keep it as it is). I think that maybe using a PTFE tube correctly cut to follow the curve of the gear is not a bad idea too. I'll try this approach and gonna design a cutting jig to perfect cut the required PTFE part.

Also Titan Extruder got this kind of piece already designed, maybe it could fit, and it would cost nothing on aliexpress.

-

@Hergonoway said in Smart Effector including toolboard-capabilities?:

I'm currently dealing with the same issue regarding the filament path right after the BMG gears in my version (the path before the BMG gears is not as critical, I'll keep it as it is). I think that maybe using a PTFE tube correctly cut to follow the curve of the gear is not a bad idea too. I'll try this approach and gonna design a cutting jig to perfect cut the required PTFE part.

The problem with using a piece of PTFE extending up into the gear area is that on retraction, the PTFE might move up (toward the gears) slightly - and then get pulled up into the gearing.

Designing the filament guide piece to have the bump area to guide filament was easier than I thought it would be in Fusion360. Start with the sketch facing the filament guide head-on, on a place centered on the filament path. Then draw a circle matching the smallest existing "hole" for the BMG gear. Then mirror that circle using the filament path as the mirror line. That leaves you the perfect area to extrude in both directions. Then fillet the new extrusions and re-do the filament hole path.

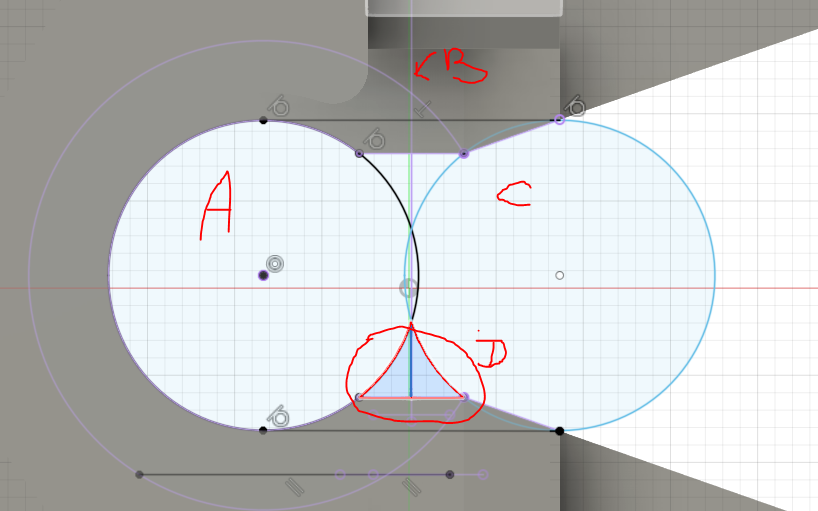

In the snippet below (of my actual sketch in 360), "A" is a 3 point circle based on 3 points projected from the inner-most gap for the BMG gear. "B" is a vertical line which is the filament path. "C" is a mirror of "A", using "B" as the mirror line. "D" is the area extruded to make the bump for the filament path. (Cleaning up the extrusions from D to meld properly with the rest of the body is annoying, but probably only because I don't know what I'm doing with Fusion360.) After that "bump" is made, I just used a 0.7mm fillet on the ridge, and then re-cut the filament path holes.

-

Here's my stab at a 74mm magball carriage for 40mm openbuild Vslot extrusions. Uses those fairly popular robotdigg metal belt tensioners to clamp the belts with the four holes in the center. I'll warn you that I'm not as good as some others in this thread with CAD

-

I am using a nimble 2 in a big delta heated chamber going up to 80-100c. Im going to print with big nozzles around .6 to 1.2. It claims this motor is high temp around 120c. Will this orbiter extruder motor do what i want or am i better off using the nimble 2 with my water cooled nema 18 off to the side. What i have works but better is always good. I guess i could maybe find a way to run water from the kryo then to the orbiter motor in my loop.

-

@garyd9

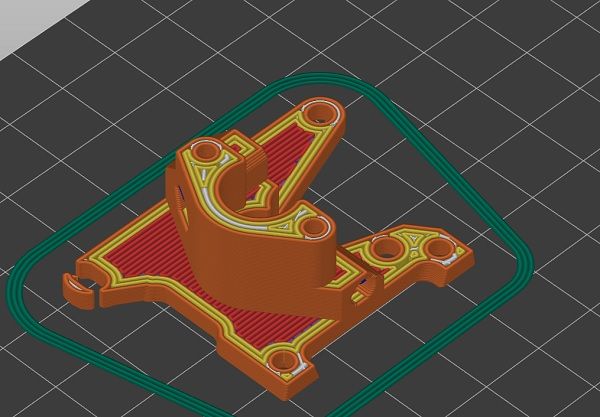

I tried to slice your version of mrac1's D3D with 0.8mm nozzle, I see a problem with the long hole for the stepper.

BTW: I found a cheaper/stronger motor for Orbiter and Sherpa mini. It's 2mm longer than the LDO. Will it still fit for the SmartEffector?

THX

Olaf -

@o_lampe said in Smart Effector including toolboard-capabilities?:

@garyd9

I tried to slice your version of mrac1's D3D with 0.8mm nozzle, I see a problem with the long hole for the stepper.You might need to enable a slicer option to extrude thin lines. I've only ever tested with a 0.4 nozzle and 0.4mm wide extrusions. If that doesn't work, load up the .step file and thicken that area.

BTW: I found a cheaper/stronger motor for Orbiter and Sherpa mini. It's 2mm longer than the LDO. Will it still fit for the SmartEffector?

That depends on your particular delta printer, what arm spacing you're using, the size of your build area in relation to the distance of the delta verticals to the build area, etc.

-

@o_lampe said in Smart Effector including toolboard-capabilities?:

BTW: I found a cheaper/stronger motor for Orbiter and Sherpa mini. It's 2mm longer than the LDO. Will it still fit for the SmartEffector?

there's a very recent alternative if you want more torque : http://ez3dpstore.com/PRE-ORDER-Sherpa-Mini--NEMA14--8t-Pinion-Motor_p_69.html

8t instead of 10t, still in pre-order state tho, but worth the wait imo

-

@hergonoway

Changing the gear ratio is just a trick IMHO, you win more torque but loose retraction speed.

They don't say much about the motor as such. Their 1004 motor has significantly different windings than the 36HS2418. It's trimmed for torque (high inductivity) but overheats fast, because of the high coil-resistance.

The motor I picked is meant for the Hitchhiker, where speed is more important than grunt. -

@o_lampe yeah heat concerns me a bit, but I generally print mechanical parts in ASA or PCmax, so it "should" be ok, I still have to print my version of the D3D tho to see it for myself. Regarding retraction speed, it implies going from 50:10 to 50:8 so there's no impact since we're dealing in the <1mm field. I could be slightly concerned for jerk but I need to test it beforehand.

That's remind me that V1 of HextrudORT should be available

-

@hergonoway

I have to read up on ASA or PCmax filaments as alternative for ABS (I'm done with that) Do they need a heated chamber? -

@o_lampe said in Smart Effector including toolboard-capabilities?:

@hergonoway

I have to read up on ASA or PCmax filaments as alternative for ABS (I'm done with that) Do they need a heated chamber?For ASA, no need. For PCmax, if you've got a chamber, I'd say it's better to use it especially if you target big printed pieces, but it's not mandatory. PC tend to build internal stress while being 3D printed. But you can anneal PCmax easily after print since glass temp is high, I usually anneal my pieces between 1h30 and 2 hour in the oven and let it temper as the oven cool down.

I personnaly don't have an heated chamber and print both without issue.

Also my advice for 2021 is to simply abandon ABS, it never has been a good material filament for FDM, just let it go. ASA is a far better alternative.

-

@hergonoway said in Smart Effector including toolboard-capabilities?:

@o_lampe said in Smart Effector including toolboard-capabilities?:

@hergonoway

I have to read up on ASA or PCmax filaments as alternative for ABS (I'm done with that) Do they need a heated chamber?For ASA, no need.

...

ASA is a far better alternative.I've been printing ABS for a few years in an old (fully enclosed) FlashForge Creator Pro (that I converted to use a Duet.) For most parts, I haven't had any problems. Once in a while if I try to print a large "solid" piece, it might split, but it's usually great for higher heat mechanical parts.

I've never tried ASA simply because it's harder to get. Spools of ABS are dirt cheap and extremely common. ASA, not so much. However, I've always read that it's nearly identical to ABS as far as printing. To me, that suggests a heated (or at least enclosed) chamber. Is that incorrect?

My favorite material for high temp resistance is a PC blend that Sno-Labs sells that they call "PC+." I can print that stuff without issue on my open air delta printer, and it has very low shrinkage (compared to ABS) which implies very low warpage. For the most part, it prints similar to PETG for me (with a higher nozzle temp of 260C and my PEI bed at around 70C.) The resulting prints are also very similar to PETG as far as strength and durability (and flexibility of the plastic.) The biggest difference is the much higher heat resistance.

-

@mrac1 could you share a step/F3z file of your double blower mod for the mosquito I definitely need to try that, it looks awesome, but I can't find it on your thingiverse page...

I assume that you've got a 713maker mount too.

I assume that you've got a 713maker mount too.I thought it was in the D3E step file, but I can't find it in either.

-

Having got a Delta i want to upgrade the electronics and add a smart effector....

Do you have any idea on a timeline for a combined smart effector and toolboard? This is something that would push me to the Duet 3 rather than the Duet 2 but i understand its difficult to plan if and when new inovations might get done

-

@opentoideas I don't think it will be available in the next 6 months, but I hope we will have it within a year.

-

thank you, that pushes me towards the Duet 3 mini - there are other upgrades I want to do so I will just change the order I do them in and hopefully the combined effector will be available by the time I run out of other things to do.

-

@dc42 that assumption seemingly has proven to be true

Still eagerly awaiting an updated smart effector. It's one of the best things that ever happened to Delta 3D printers imho but with InputShaping coming up and more and more featherweight extruder designs an integrated accelerometer or refresh of the SE altogether would be very welcome

-

I wanted to add this has been a educational thread for me as to some of the constraints on Delta designs.

I don't know if I would switch to a smart effector over the SE300 but a revision that includes this would make me give consideration to losing the print area outside the triangle of the towers.

-

undefined Fred-Y referenced this topic

undefined Fred-Y referenced this topic