Pressured air cooling controlled with servo and ball valve

-

i did this with limited success for a servo on out7 with ballvalve,

i created a macro called airservovalve with the below

; AirValveServo

if fans[0].actualValue = 0

M280 P1 S0 ; Close the valve

elif fans[0].actualValue >= 0.01 && fans[0].actualValue <= 0.10

M280 P1 S18 ; Open valve 10%

elif fans[0].actualValue >= 0.11 && fans[0].actualValue <= 0.20

M280 P1 S36 ; Open valve 20%

elif fans[0].actualValue >= 0.21 && fans[0].actualValue <= 0.30

M280 P1 S54 ; Open valve 30%

elif fans[0].actualValue >= 0.31 && fans[0].actualValue <= 0.40

M280 P1 S72 ; Open valve 40%

elif fans[0].actualValue >= 0.41 && fans[0].actualValue <= 0.50

M280 P1 S90 ; Open valve 50%

elif fans[0].actualValue >= 0.51 && fans[0].actualValue <= 0.60

M280 P1 S108 ; Open valve 60%

elif fans[0].actualValue >= 0.61 && fans[0].actualValue <= 0.70

M280 P1 S126 ; Open valve 70%

elif fans[0].actualValue >= 0.71 && fans[0].actualValue <= 0.80

M280 P1 S144 ; Open valve 80%

elif fans[0].actualValue >= 0.81 && fans[0].actualValue <= 0.90

M280 P1 S162 ; Open valve 90%

elif fans[0].actualValue >= 0.91 && fans[0].actualValue <= 1.0

M280 P1 S180 ; Open valve 100%Then in Daemon.g added this

M98 P"0:/macros/Special Scripts/AirValveServo"The only issue was it was a bit slow responding to fan speed changes

-

-

@mikedc

Isn't it better to 'scale' the incoming PWM value to the required servo-angle?

You need to know: min_in, max_in, min_out, max_out.[**pseudo** code] var scale_factor = {(max_out - min_out) / (max_in - min_in)} var servo_out = {scale_factor * (fans[0].actualValue - min_in) + min_out}There's a standard formula to scale variables, but I couldn't write it down from memory.. Have to google it..

//edit This should work, just have to put it in clean gcode-meta -

@o_lampe maybe yes, but when i was trying this it was the only way i could get it working

-

So just to recap, these are my values:

- min_in = 0 (M106 S0 ->Fan off)

- max_in = 255 (M106 S255 -> Fan full on)

- min_out = 0 (M280 P0 S0 -> Servo at 0° -> valve closed)

- max_out =90 (M280 P0 S90 -> Servo at 90° -> valve fully open)

So my code should look like this ?

[**pseudo** code] var scale_factor = {(90 - 0) / (255 - 0)} var servo_out = {scale_factor * (fans[0].actualValue - 0) + 90} M280 P0 S{var.servo_out}I have not used G-Code meta commands before, so I would need a little help here to put this in clean meta code and make this work.

-Max

-

@maxgyver

I haven't written anything in Meta-code yet, but I read a little.

E.g. the waved brackets {} are mandatory for the outmost math-expressions.

If you want to test it, you can replace M280...with a harmless echo P"var.servo_out"I believe, there is a way to call daemon.g more often to get a faster response, maybe the experts can chime in here?

For later editing it could be useful to put the min/max values in variables too, otherwise you can cut a few corners, where a value is zero.

-

@maxgyver

You would probably be better off declaring global variables in config.g then updating the value in your macro ( or daemon.g)

If you're running in daemon.g it just seems counter productive to be declaring and freeing variables constantly.Config.g

; create variables - must be after servo is created global scale_factor = {(90 - 0) / (1 - 0)} ; no need for the math in this instance but it makes it clear how you arrive at the value. global servo_out = 0 ; set to zero initially M280 P0 S{global.servo_out} ; start with valve closedDaemon.g

set global.servo_out = {global.scale_factor * (fans[0].actualValue - 0) + 0} ; calculate position required M280 P0 S{global.servo_out} ; adjust valve position.You could optionally use an IF statement to only adjust when required, which I suppose would reduce the traffic and cpu time by a tiny amount.

-

@maxgyver said in Pressured air cooling controlled with servo and ball valve:

So just to recap, these are my values:

- min_in = 0 (M106 S0 ->Fan off)

- max_in = 255 (M106 S255 -> Fan full on)

- min_out = 0 (M280 P0 S0 -> Servo at 0° -> valve closed)

- max_out =90 (M280 P0 S90 -> Servo at 90° -> valve fully open)

Actually , thinking about this, the value you get back from fans[0].actualValue will be in the range 0-1, not 0-255

You will need to change your code accordingly. -

It's a rainy day here, so for something to do I decided to fully test this.

Using a YM2763 13kg/cm hobby servo (externally powered so as to not risk damaging the duet).

This has an input range of 0-180 which corresponds to the angle.Please refer to the notes for M280 as other servos may require different values

It's not really necessary to create variables for all settings, but it makes adjustment and readability easier.

in config.g

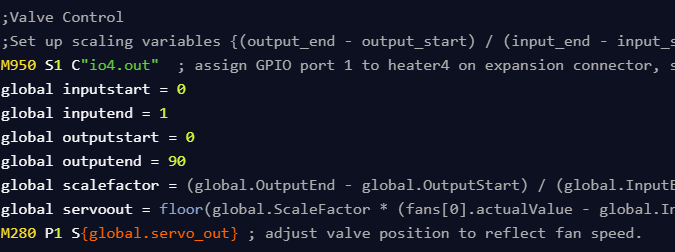

;Valve Control ; Set up scaling variables {(output_end - output_start) / (input_end - input_start)} M950 S1 C"exp.heater4" ; assign GPIO port 1 to heater4 on expansion connector, servo mode global InputStart = 0 global InputEnd = 1 global OutputStart = 0 global OutputEnd = 90 global ScaleFactor = (global.OutputEnd - global.OutputStart) / (global.InputEnd - global.InputStart) ; no need for the math in this instance but it makes it clear how you arrive at the value. global ServoOut = floor(global.ScaleFactor * (fans[0].actualValue - global.InputStart) + 0.5) + global.OutputStart ; calculate position required on sevo - use floor() to apply rounding M280 P1 S{global.servo_out} ; adjust valve position to reflect fan speed.in daemon.g or macro

set global.ServoOut = floor((global.ScaleFactor * (fans[0].actualValue - global.InputStart)) + 0.5) + global.OutputStart ; calculate position required - use floor() to apply rounding to nearest whole number ;echo {global.ServoOut} M280 P1 S{global.ServoOut} ; adjust valve attached to servo on P1 to reflect scaled fan speed. -

@owend

Thank you for chiming in!

Can you confirm that in math formulas no waved brackets are necessary, but when I call eg. M280 the parameter has to be wrapped in {}?

How do I know, I have enough free memory to write longer meta-code? (AI for TicTacToe can get quite voluminous) -

@o_lampe said in Pressured air cooling controlled with servo and ball valve:

@owend

Thank you for chiming in!

Can you confirm that in math formulas no waved brackets are necessary, but when I call eg. M280 the parameter has to be wrapped in {}?Correct on both counts

How do I know, I have enough free memory to write longer meta-code? (AI for TicTacToe can get quite voluminous)

You can use M122 to see how much of the heap is used.

See here -

@owend

I just found this thread, please see my reply there -

@OwenD and @MaxGyver

Thinking further and having pity with the servo, it would be better to add a 'hysteresis' in the code, such as[pseudo code] If (abs(new_fan_value - old_fan_value) > hysteresis) go on else breakThat's not necessarily a problem with fan-values changing in big numbers, but a Servo also has a'deadband' which you have to keep in mind. (and for further reference, if someone wants to reuse the code for something else)

-

I am getting the following error after inserting your code in my config.g

"Error: Failed to read code from macro config.g: Failed to parse major G-code number (lobal) in line 85"

To me, it looks like the global variable are not recognized by the firmware:

I am using firmware version 3.3-b2.

-

You have written servoout and also servo_out.

-

@o_lampe said in Pressured air cooling controlled with servo and ball valve:

You have written servoout and also servo_out.

Nope, this did not cause the error...

"Error: Failed to read code from macro config.g: Failed to parse major G-code number (lobal) in line 4"

;Valve Control ; Set up scaling variables {(output_end - output_start) / (input_end - input_start)} M950 S1 C"io4.out" ; assign GPIO port 1 to heater4 on expansion connector, servo mode global InputStart = 0 global InputEnd = 1 global OutputStart = 0 global OutputEnd = 90 global ScaleFactor = (global.OutputEnd - global.OutputStart) / (global.InputEnd - global.InputStart) ; no need for the math in this instance but it makes it clear how you arrive at the value. global ServoOut = floor(global.ScaleFactor * (fans[0].actualValue - global.InputStart) + 0.5) + global.OutputStart ; calculate position required on sevo - use floor() to apply rounding M280 P1 S{global.ServoOut} ; adjust valve position to reflect fan speed. -

@maxgyver

@maxgyver

I'm assuming you are running the correct versions on DWC, etc etc

We are both running RRF3.3b2 and it works for me.

I'm on a Duet 2 wifi.

I don't have a duet 3, but I suspect it's actually coming from your M950 command on the previous line.

Either that are it's one of this SBC specific issues.What happens when you run those commands individually from the console command line?

-

@o_lampe

That was actually my error in the original. -

@maxgyver said in Pressured air cooling controlled with servo and ball valve:

G-code number (lobal)

Your parser believes global is the beginning of a move command and it can't parse "lobal" as number (0,1,2,3,4 expected)

I'm with @OwenD it might be related to SBC issues. -

@owend said in Pressured air cooling controlled with servo and ball valve:

(...)I suspect it's actually coming from your M950 command on the previous line.

Either that are it's one of this SBC specific issues.It's not the M950 command (I have checked by commenting out this line)

@owend said in Pressured air cooling controlled with servo and ball valve:

What happens when you run those commands individually from the console command line?

I get the same error message.

-Max