36HS2418 = stronger motor for Orbiter extruder

-

hi,

@o_lampe Did you use this wantai stepper? if yes how hot becomes this motor? -

@siam

I'm currently printing a bracket for it. I won't run it with more than 1.2-1.4A, so temps should be reasonable.I will report.

OlafPS: there doesn't seem to be a printable 'Sherpa mini"?

-

@o_lampe said in 36HS2418 = stronger motor for Orbiter extruder:

there doesn't seem to be a printable 'Sherpa mini"?

Files are here: https://github.com/Annex-Engineering/Sherpa_Mini-Extruder

Ian

-

There are a variety of motors that should work. I don't know enough about the choices to make really good choices, but I have found that sometimes lower power motors are better for acceleration and jerk. (It has something to do with inductance, inertia, etc - but I'm not an electrical engineer so I don't quite follow the reasoning.)

From what I've read (which means that it might be completely untrue), certain brand stepper motors are just generally better than others for this type of thing. I've often seen "Moons" listed as a brand giving extremely good performance, but they are usually outside of my budget when shipping is added in.

LDO has at least 2 motors that should work with this application: 36STH171004AHG and 36STH200504AHG (both are listed as working with the orbiter.) Wantai probably has 2 or 3. I've seen references to people using Wantai 36BYGH218 with the orbiter. There's a good chance that Stepperonline has 1 or 2 NEMA14 models that have the same size spur gear, but I haven't seen any references of people using one of them with the mini extruders.

I believe some extensive testing has been done comparing some of them when used with the orbiter: Scroll to the lower 1/3rd of this thingiverse description: https://www.thingiverse.com/thing:4725897

(Note that the designer of the Orbiter has a financial association with LDO. I doubt that influenced his testing, but it's only fair to mention it when referring to his tests.)

-

@o_lampe I was told that LDO's max current spec is wrong and that they also tested the max torque wrong. In reality their max current is more like 500mA.

-

I made a 1h testrun at 1.2A and the motor was too hot to touch, but below 100C (tested with waterdrop)

Then I repeated the test with 0.8A and the motor was 'warm'.

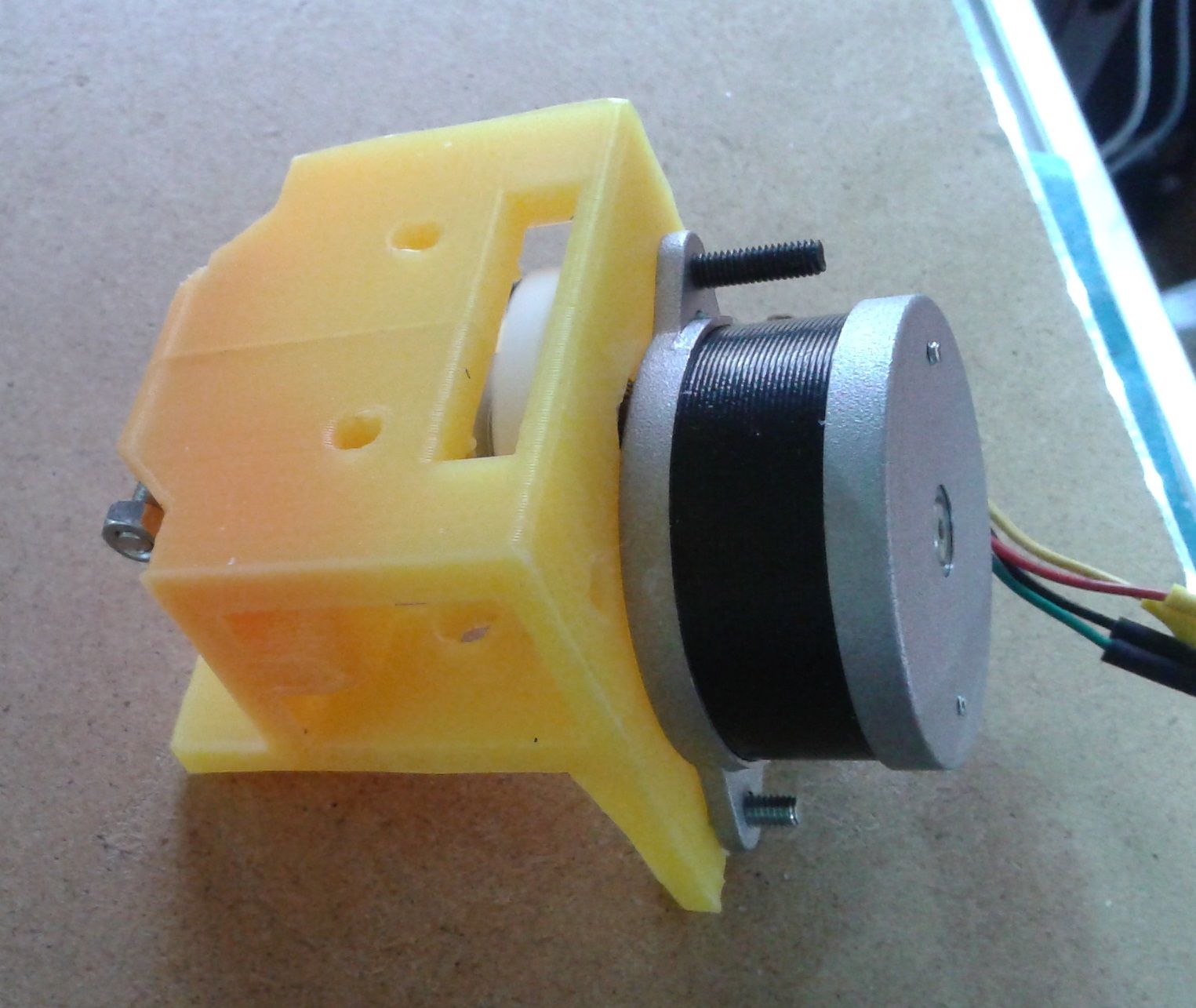

The bracket I made is from 'colorchanging' filament. It changes from orange to yellow above 33*C. (quite nice visual indicator for fan-shrouds, too)

At 1.2A the heat crept very far

30min later at 0.8A (the material takes a while to change back to orange...)

After cooling down I removed the motor and I could see an 'imprint' of the stepper.

I noticed the screws were already loose. There was a beginning meltdown at 1.2A. (the bracket, not the motor)First conclusion: the sweat spot for this motor is somewhere below 1A, but 800mA is safe.

With a clever fan duct for the hotend (blowing air towards the motor) it could probably run 0.9A all day long. -

@garyd9 said in 36HS2418 = stronger motor for Orbiter extruder:

I've seen references to people using Wantai 36BYGH218

According to their datasheet, it's identical to my motor. The differences are often hard to see and are related to cable outlet, wire length and connector. It seems the 10 teeth/0.5 module pinion is standard for those mini-pancakes. I didn't know that and was happy to confirm it matches BMG gears.

-

@o_lampe Sounds like it would work fine if the bracket/extruder was printed with ABS or PC. (My current extruder is ABS printed.) On the other hand, with the LDO motor that I'm using, I have power at 350mA and it barely gets warm.

What advantage is there to running much more power? It seems that if the motor has to work that hard to push the filament, that perhaps the hotend isn't hot enough.

I'll admit that my experience is limited, so please help me expand my knowledge.

-

@garyd9

I'm using a volcano hotend with 0.8mm nozzle. Heating is not the problem, but the extruder runs much faster (4 times faster than with 0.4 nozzle) You can't achieve those speeds with 350mA.

Furthermore I print infill every second layer which means 0.9x0.5mm cross section. I use a heavy 1.7A NEMA17 with a standard BMG for this task and I'd like to spare some weight with a smaller motor, but higher gear ratio.

Next on the list: I want to use a Maestro board in the future and have to reduce max. current to 1.2-1.4A. (if possible, with least performance loss) -

Guess what!

I have ordered 3 more motors from actmotors on ebay, and what did they sent me as freeby?

Not the usual Haribo, but 5 covid medical face masks

-

@o_lampe said in 36HS2418 = stronger motor for Orbiter extruder:

they sent me as freeby?

Not the usual Haribo, but 5 covid medical face masks ...Meh, Stepperonline give Covid vaccines.

-

undefined o_lampe referenced this topic

undefined o_lampe referenced this topic