Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning

-

@dc42 My accelerometer is in the mail. When will 3.3 beta 3 be released?

-

@generisi said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

@dc42 My accelerometer is in the mail. When will 3.3 beta 3 be released?

As soon as I have a fix for the issue of spurious VIN undervoltage reports on Duet 3 Mini with attached SBC. If your accelerometer arrives before then, there is a preview available at https://www.dropbox.com/sh/b65da04w1gl94nf/AACLpPslfDiWDlJN5KDdPydAa?dl=0.

-

I assume this works for a Cartesian style machine.

I'd mainly be looking to address the "springyness" in my polar bed due to the large drive belt and bed inertia. At the moment I keep the acceleration and max rotation speed fairly low, but I'm updating the bed drive to closed loop so I can push it harder.

Is this something that'll help, and if so will I be able to use the accelerometer on the rotating bed to identify the relevant frequencies?

Just looking to understand how it'll integrate with the polar printer.

I'm guessing that once I've converted my Wanhao D4S to my recently purchased Duet3 mini card this'll all be directly relevant.

Just one final thought, if I have several different mass tool heads will I be able to assign different frequencies for each of them?

Really interesting stuff folks!

All the best

Barry M -

@cncmodeller said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

I assume this works for a Cartesian style machine.

If you mean the input shaping, then yes, although so far I have only tested motion on a CoreXY machine, and not tested extrusion. The accelerometer support should work with any kinematics.

Is this something that'll help, and if so will I be able to use the accelerometer on the rotating bed to identify the relevant frequencies?

Possibly, depending on the nature of the drive between the motor and the bed.

I'm guessing that once I've converted my Wanhao D4S to my recently purchased Duet3 mini card this'll all be directly relevant.

Duet 3 Mini is a good choice, because it has enough spare RAM and flash memory to take further than we can take the Duet 2 WiFi/Ethernet.

Just one final thought, if I have several different mass tool heads will I be able to assign different frequencies for each of them?

Yes, by including M593 commands in your tool change files.

-

@dc42 said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

@cncmodeller said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

Possibly, depending on the nature of the drive between the motor and the bed.

Hi @dc42

The polar bed drive arrangement can be seen in the linked video.

https://youtu.be/I-7yMkPdsTQ?t=121

I'm now back to direct drive without a gearbox and A much bigger stepper.

The bed pulley is a custom laser cut 720 tooth gt2 profile with a 1100 tooth (ish) belt to the 20 tooth pulley on the stepper motor.

Pulley construction:

https://youtu.be/KNGRAxSSkAQ -

@dc42 Thank you!

-

@printernoodle said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

So exciting....this is a wonderful addition to the ecosystem.

Looks like it gained good momentum.

-

@dc42 any chance that a future version of the toolboard could/would have the accelerometer baked into it, or an expansion header to work with say the adafruit board?

-

@nuramori

Good thought! That would also help to find different resonances on different toolheads (regarding weight) -

Here is a demonstration of input shaping:

https://www.youtube.com/watch?v=ePQ7LjKKB68

This one is wide band and supports pendulums of different frequencies:

https://youtu.be/MfLavweSiRo?t=18

Looks like magic to me, especially the fact that it's done in an open loop.

-

@dc42 Do you have an STL file that you are using to mount the accelerometer on your toolchanger? If not, I'll make one and post it.

-

@zapta said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

Here is a demonstration of input shaping:

https://www.youtube.com/watch?v=ePQ7LjKKB68

This one is wide band and supports pendulums of different frequencies:

https://youtu.be/MfLavweSiRo?t=18

Looks like magic to me, especially the fact that it's done in an open loop.

That's amazing...

@zapta I'm with you on that one... absolutely black magic!!!

-

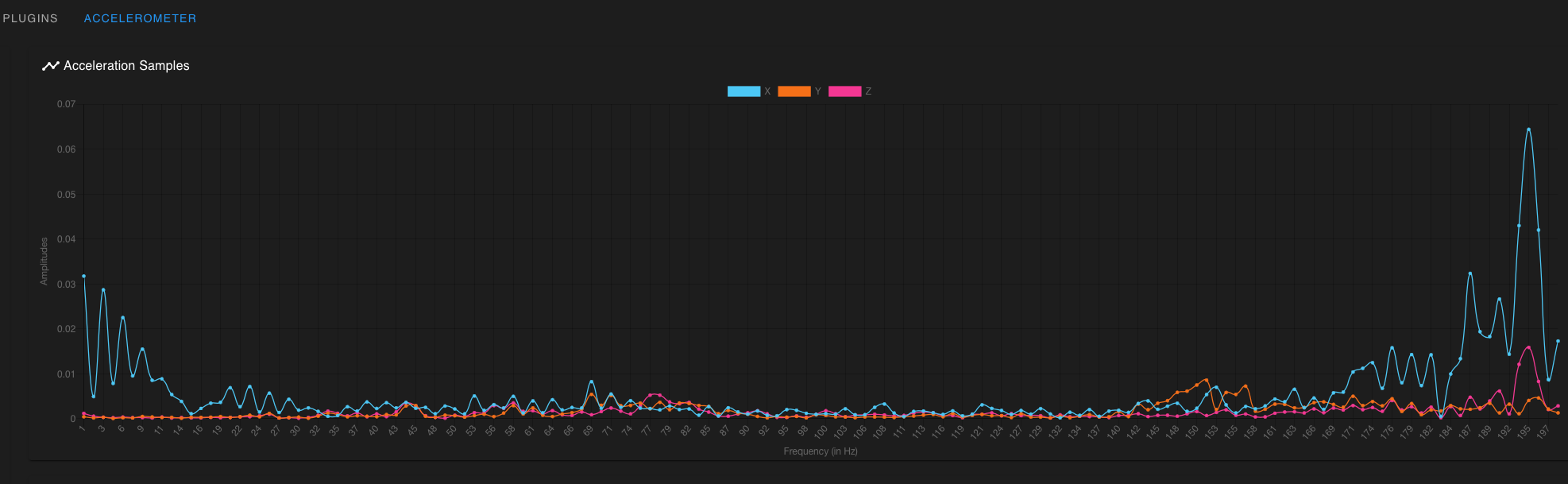

The Accelerometer saves so much time and filament finding the best frequency even for the basic DAA shaper.

M593 off

And with DAA:

Can't wait for the "real" shapers

-

My accelerometer has just arrived... Something else to tinker with when time permits.

As my printer bed moves with the part on it, I was thinking that for large parts the natural frequency will change. This begs the question could there be a way to change the parameter during a print based on the amount of filament extruded?

Just thinking out loud for now.

-

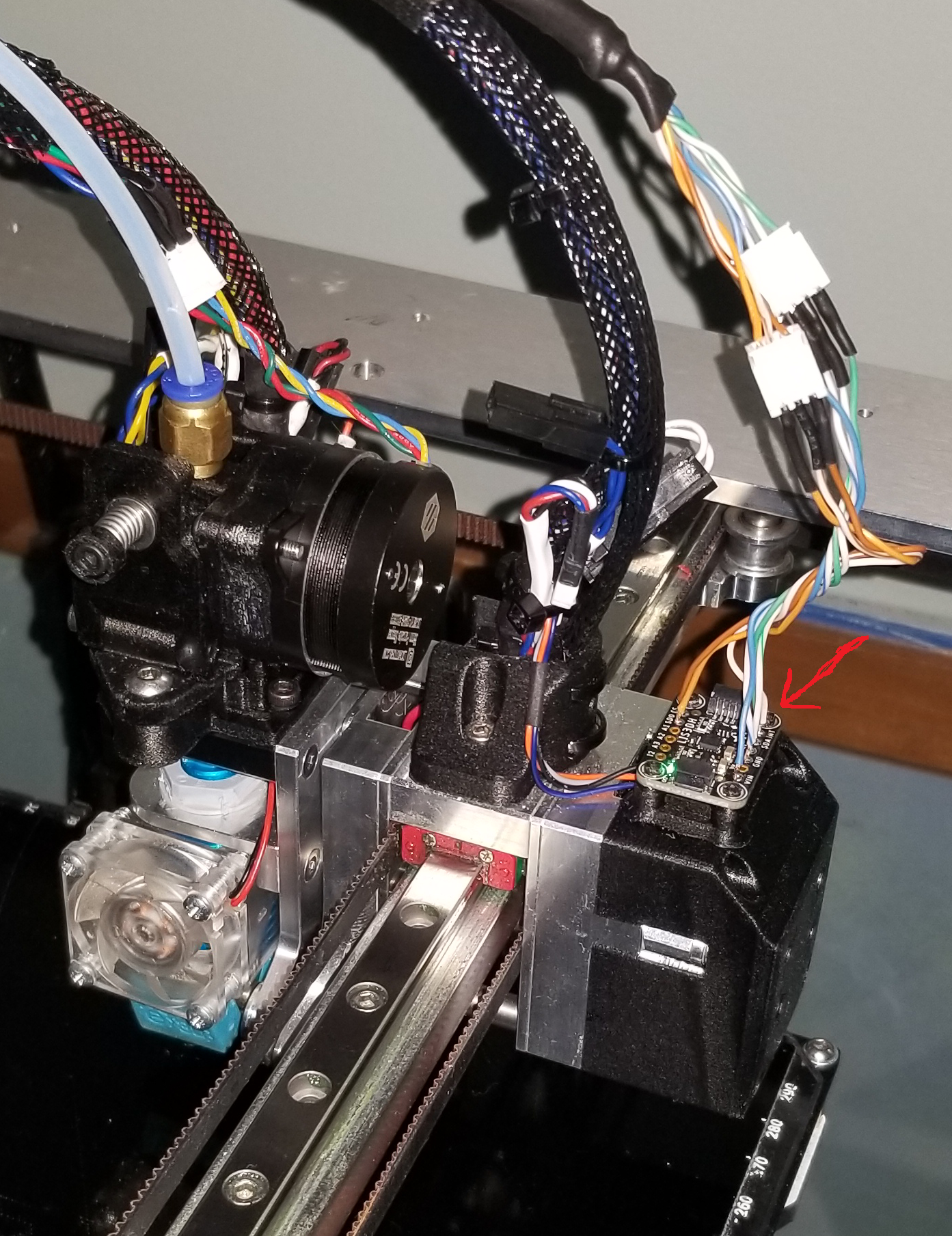

@dc42 I have my accelerometer set up on my tool changer. I mounted it like this:

Are any of the input shapers in the version you put into the dropbox?

Thanks!

-

@dc42 FWIW - I also am thinking that the table the printer is on vibrates. Could a second accelerometer could be used to measure the vibration of the printer frame and subtract it from the samples collected on the carriage? The accelerometer is measuring all vibrations, not just the vibrations of the carriage inside the printer frame. I know that samples would have to be synchronous, or perhaps asynchronous and the Fourier results of the frame vibration subtracted from the Fourier results of the carriage vibration?

-

Input shapers to generally have a range they reduce vibrations so it's not only a specific frequency they dampen but + / - x% from the specified input shaping frequency. Depending on the shaper the range is smaller or bigger.

Nevertheless it is possible to change the input shaping frequency during a print.The object "move.extruders[0].position" should display the total amount of filament used so far and with some conditional gcode in the daemon.g you should be able to achieve your goal.

-

@generisi said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

I know that samples would have to be synchronous, or perhaps asynchronous and the Fourier results of the frame vibration subtracted from the Fourier results of the carriage vibration?

By using the same file for both tests, one could write a specific start- and end movement (a number of fast/short back and forth moves) which would allow to match the results. (*) The input shaper would have to search for these patterns...

*) calling a macro M98 P"ShakeItBaby.g"

-

@cncmodeller said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

could there be a way to change the parameter during a print based on the amount of filament extruded?

Adding filament will change the frequencies, but it also depends where you put it. In case of a Cartesian, the layer height has an influence. In case of a Polar bed, even the distance from bed-center is important.

Then each layer of plastic adds a different amount of flexibility (PLA vs ABS, vs PETG)

It's impossible to digest all that in a theoretic shaper model.

Better measure online and correct on the fly -

Instead of input shaping, for global vibrations one could also create vibrations in opposite direction like a noise cancellation system for earphones. Maybe Piezo based, using LIS3DH as source of information.