VFD control options

-

@t3p3tony

RS 485/modbus is the most popular way to control the cheaper VFD's on the market.

Here's a link to the manual http://www.jinlantrade.com/ebay/invertermanual.pdf

I currently operate mine with a 0-10v PWM to Analogue converter board but its not great at keeping the RPM consistent.

RS 485 has the ability to close the loop.

Ideally native support would get my vote but if not, using a USB to RS485 adapter and then a plugin for SBC would be the next best thing. -

@t3p3tony

RS485/Modbus is definitely a good option if its available.Unfortunately my experience is that whilst the manuals for the cheaper VFDs available on ebay quote RS485, in practice it's not fitted, leaving analogue control as the only option.

Although written for an AskPower VFD, the following notes might be helpful as the interfaces are quite generic between different low cost VFDs.

https://forum.duet3d.com/topic/19968/duet-integration-with-an-askpower-a131-vfd?_=1619463819814

My experience is that spindle speed regulation is pretty good provided the control voltage is stable and delivered from a low impedance source. However, this may be because I'm typically machining aluminium and this may not place great demands on the VFD control loop?

The control linearity (PWM -> RPM) is around 5% which is good enough, but using the VFD feedback pulse to gently close the loop would be neat.

-

Not that I have a CNC with a VSD on it at the moment, but I deal with VFD's on a daily basis with PLC's and pump station controllers. The biggest issue with doing it via modbus whether it be RS485 or TCP/IP is the fact that the modbus registers are different between almost every VFD manufacturer and sometimes different between models within the same manufacturers range. What ever you do you would need to be able to customize the registers that you are writing to and reading from. Also some you might write a frequency to and others need it as a % of permissible speed range taking into consideration the min and max speed. Having some form of analog output support (Extension board) would be a far better option unless you align the code with certain models but that would be a huge undertaking as everyone uses different drives.

In terms of features you could use, you could add current feedback so you could optimize feedrate's. Although you can do it via analog as well if you have an analog input channel (plus usually a digital output from the VFD), Modbus would make it easier, you could read the current feedback and whether the motor was on current limit to slow feedrate's down.

Just a few thoughts.

Sam

-

Why not have a look at LinuxEMC?

Their code base is pretty mature and they have already done a LOT of testing/debugging as a community?

Me: 0-10V to dedicated PWM Servo Amp that does everything in its own little balck box. Sorry I'm not much more help.

-

@samlogan87 said in VFD control options:

you could read the current feedback and whether the motor was on current limit to slow feedrate's down.

...what Sam said, plus adding a thermal control. With reversed logic from our classic hotend fans. (slow down spindle when crossing a temp-threshold)

-

@sinned6915 said in VFD control options:

0-10V to dedicated PWM Servo Amp that does everything in its own little balck box.

Part of the question is what "everything" is in this context.

-

I find with my PWM to analogue converter I get a variation in RPM of around 5-600 RPM.

I currently use heater outputs to control when the spindle is on or off.

Feedback of the speed will allow a lot more control, such as waiting for the spindle to reach speed etc without having to put a delay in the gcode -

It is a shame 0-10V is so widely used in the smaller cheaper drives as it is such a horrible analog signal to use. 4-20mA is becoming much more widely used (and has been for quite some time) as it will fault on cable break and does not worry (Until a certain point) about extra resistance causing voltage drop and therefore incorrect inputs into the VSD.

As I think I mentioned above, I would almost think that an expansion board for VSD control is a good idea with extra inputs and outputs to cover off Start and Stop, Direction, Reference Speed, Digital Input for Current Limit (Mostly for reference as often the VSD is hidden) and current feedback, which can subsequently be used with some form of loop to scale the feed rate down to ensure you do not overload the motor.

Sam

-

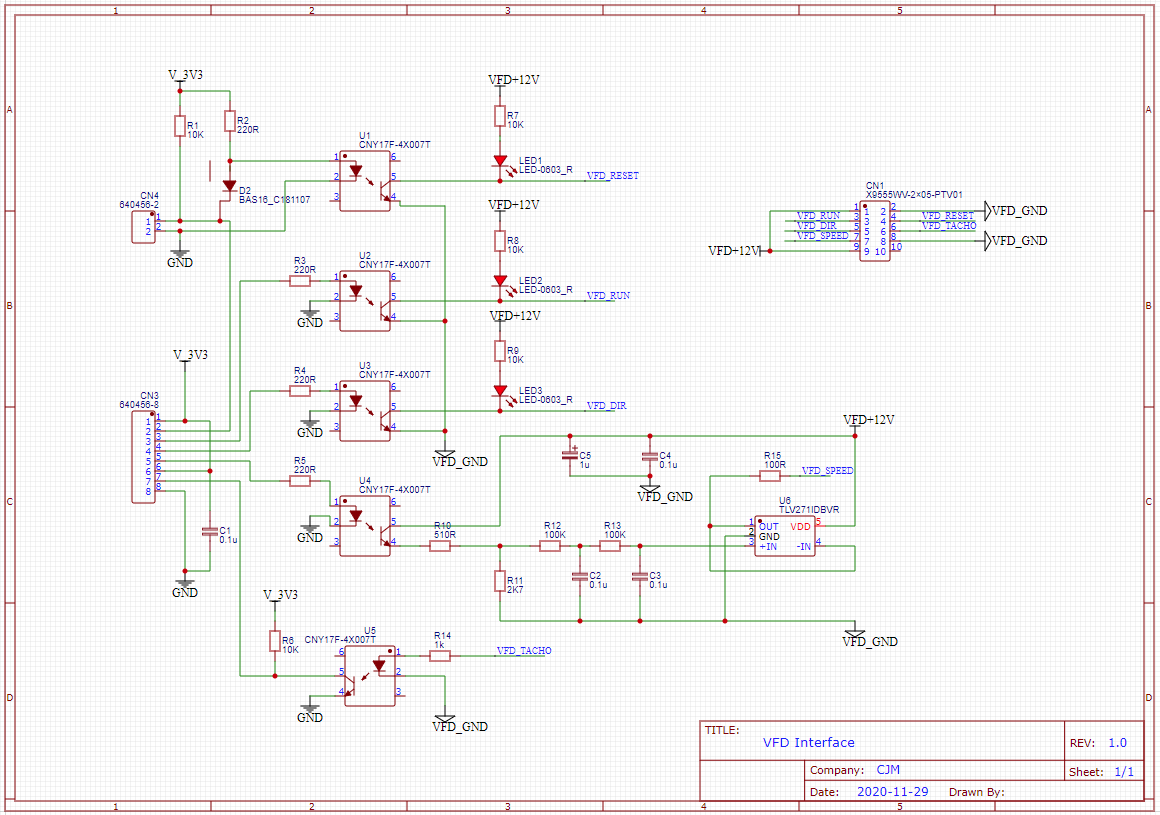

@t3p3tony To answer your question about what "everything" is, the circuit below is an example of a very simple opto-isolated interface that delivers all the key output signals needed to control pretty much any low cost VFD (as far as I can see):

VFD Speed

VFD Run/Stop

VFD Direction

VFD ResetIt is powered on the VFD side by the +12V supply commonly available from such VFD and on the Duet side by the +3.3V supply.

The circuit also provides an opto-isolated input so the Duet can read the tacho pulse from the VFD Frequency connection.

As identified by several people across the Duet3D CNC forum, this would allow:

a) display of the actual spindle RPM on the Duet Web Interface;

b) M3, M4 and M5 commands to wait for the spindle to get to speed before moving to the next G-code command; and

c) adding a feedback loop to be implemented around the VFD to improve spindle RPM stability and control during machining.The current limit and current feedback connections that Sam mentions certainly sound useful, but I haven't come across them in the low cost VFD I've investigated or worked with, so I'm afraid I can't comment on how they could be implemented.

Schematic_VFD Interface_2020-11-19.pdf

I developed this for my own personal use and if it's helpful, anyone may use/develop it as they wish - but no warranties are offered or implied!

-

@cjm said in VFD control options:

The circuit also provides an opto-isolated input so the Duet can read the tacho pulse from the VFD Frequency connection.

In another thread I asked, how fast the external triggers could be read (10kHz?), but @dc42 said, they are not that fast, since they don't run in the main loop.

Do you have different experience? On which pins? -

-

@o_lampe The normal approach to measure the frequency of a repetitive pulse like the VFD tacho with a micro-processor would be to connect it as the clock input to a counter/timer configured to count pulses within a given time window (e.g. 0.1 second). At the end of each time window the timer generates an interrupt and the micro reads the count which is directly proportional to the tacho pulse frequency. In this way, the processor only needs to read the timer count infrequently, without being limited by the micro's code execution.

@T3P3Tony This link describes how to attach a fan with tacho pulse output to either a Duet 2 or 3 so, as you mention, there appears to be hardware provision to read a tacho signal and RPM already:

https://duet3d.dozuki.com/Wiki/Connecting_and_configuring_fans

I wonder if the fan RPM is accessible through the Duet Object Model? If so, then for CNC use, it should be relatively straightforward to repurpose the fan RPM value for spindle speed display on the CNC version of Duet Web Control.

-

@cjm fans.N.rpm is the object model key you are looking for.

-

@t3p3tony Thanks! Hopefully I can try this over the weekend.

-

The above drive manual shows it has a voltage output for frequency feedback. Surely that is a more simple way of getting feedback for rpm.

Sam

-

@samlogan87 The motivations for using a tacho pulse rather than voltage were:

a) it is easier to opto-isolate;

b) if the tacho pulse is derived from the VFD motor drive signal then in principle, the tacho frequency should be precisely related to spindle speed; and

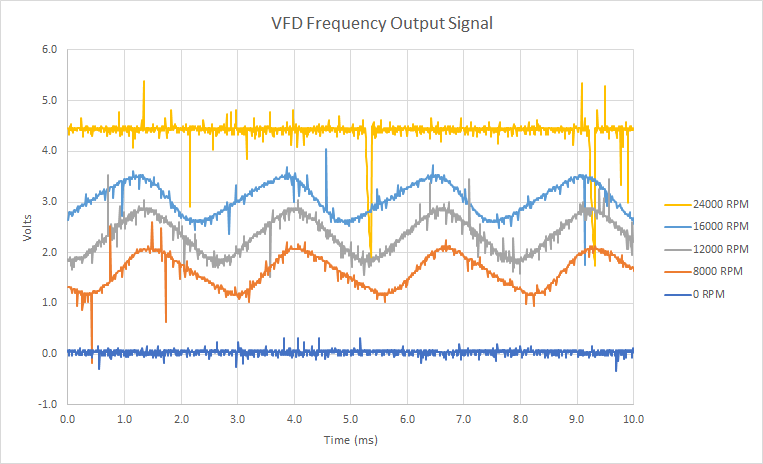

c) it's what I had understood was being output by my VFD's frequency output terminal.However, a little bank holiday tinkering has shown that what my low cost VFD actually provides on its frequency output is not a tacho pulse but a voltage (kudos to Sam!).

It's not a very clean voltage:

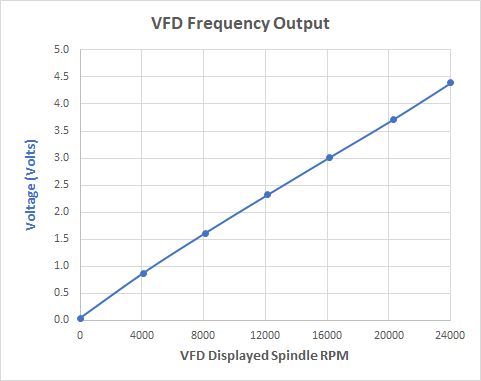

Nonetheless, the DC level appears to be proportional to the displayed spindle RPM:

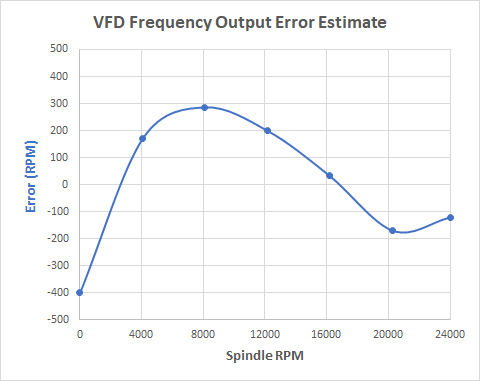

A simple linear fit indicates that the RPM could be calculated from the voltage with an error of roughly +/-300 rpm:

A second order fit roughly halves the error, reducing it to +/-0.6% of full speed:

So, it looks as though this analogue VFD frequency output could give a useful indication of actual spindle RPM.

This leaves the question for "me and my CNC" of how to get this voltage into the Duet, preferably via an opto-isolated interface...

voltage to frequency converter (e.g. LM331) -> opto-isolator -> Duet exp.b6?

Σ-Δ modulator ADC -> isolator -> Duet exp.b6 -> digital filter?

ADC -> isolated spi/i2c? -> Duet spi/i2c?

?

? -

@cjm opto isolation isn’t new with analog signals. We use them a fair bit to protect against burning up plc inputs or vsd inputs and they are generally cheap so shouldn’t be hard to implement. However I have absolutely no experience with designing and build pcb’s so shouldn’t be commenting

Sam

-

@samlogan87 @T3P3Tony

I used an old Arduino to convert my VFD's "frequency output" (0-5.0V) voltage signal into a square wave whose frequency is proportional to the spindle RPM i.e.

VFD 24000 rpm -> 5.0V -> 400Hz square wave.

This square wave drives the Duet's ext.b6 pin via an opto-isolator.The fans[0].rpm object model key gives the following results compared to the demanded M3 rpm and the RPM displayed on the VFD:

M3 S VFD Fans[0].rpm 24000 24000 12000 20000 20154 10150 16000 16169 8123 12000 12118 6103 8000 8154 4117 4000 4083 2090 0 0 0The fans[0].rpm result look to be half the expected result, presumably due to fans normally having 2 pulses per revolution?

Allowing for this factor of 2, fans[0].rpm tracks the VFD/spindle frequency quite well (~0.3% error).

Ideally one would like to use config.g to define a pin as the spindle tacho source (and an associated scale factor) so that the "Current RPM" could be properly displayed. Might this make be added to a future Duet firmware update?