differences between manual and automatic leveling

-

@gip_86 said in differences between manual and automatic leveling:

So and what are the best steps for next?

Have you made the configuration settings needed to use the Manual Bed Leveling Assistant?

Once that is done and the bed is level you should then proceed to get Mesh Bed Compensation working.

Frederick

-

@fcwilt

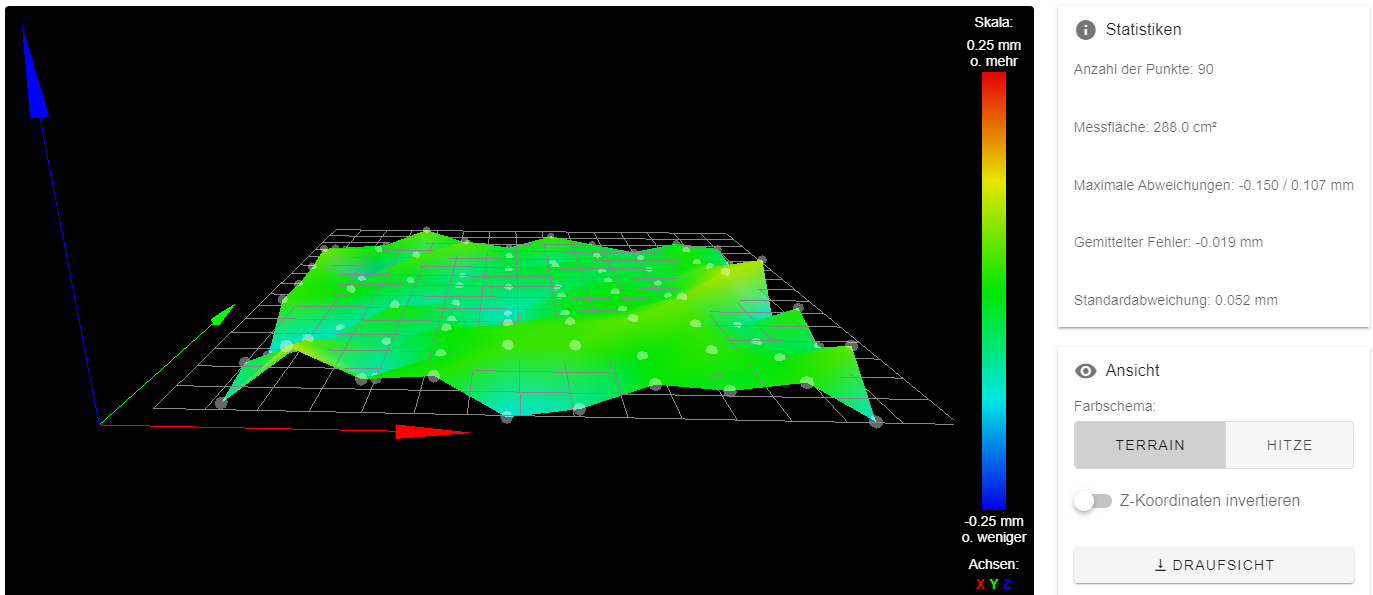

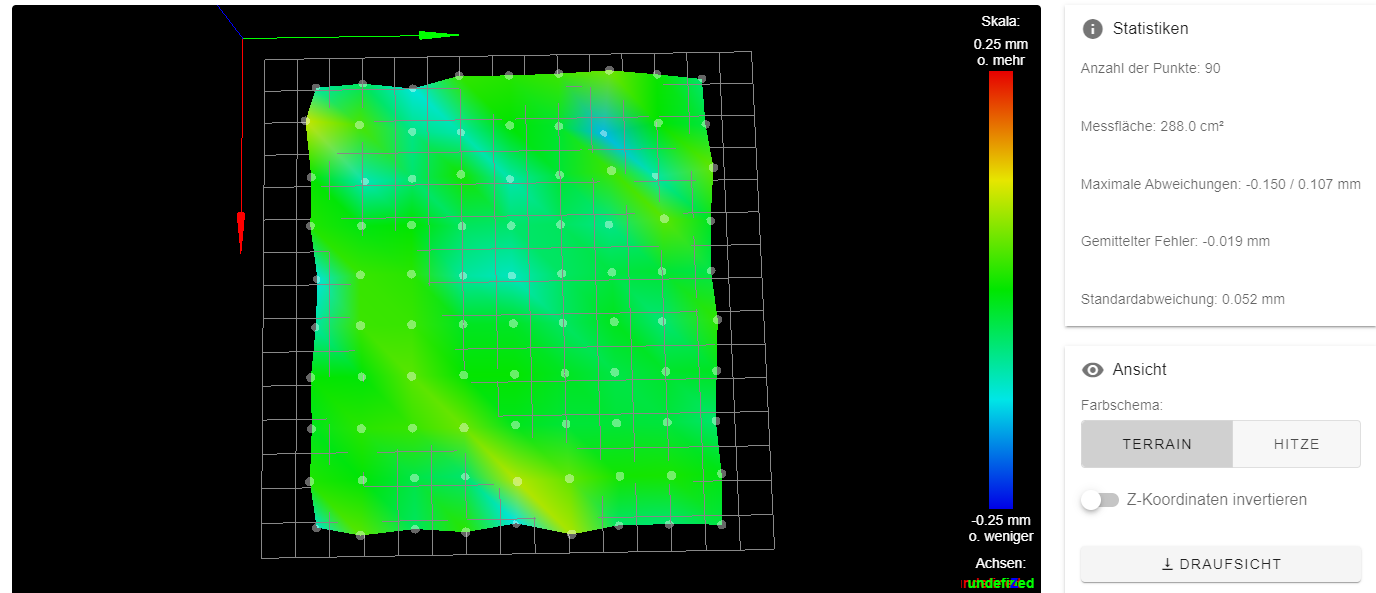

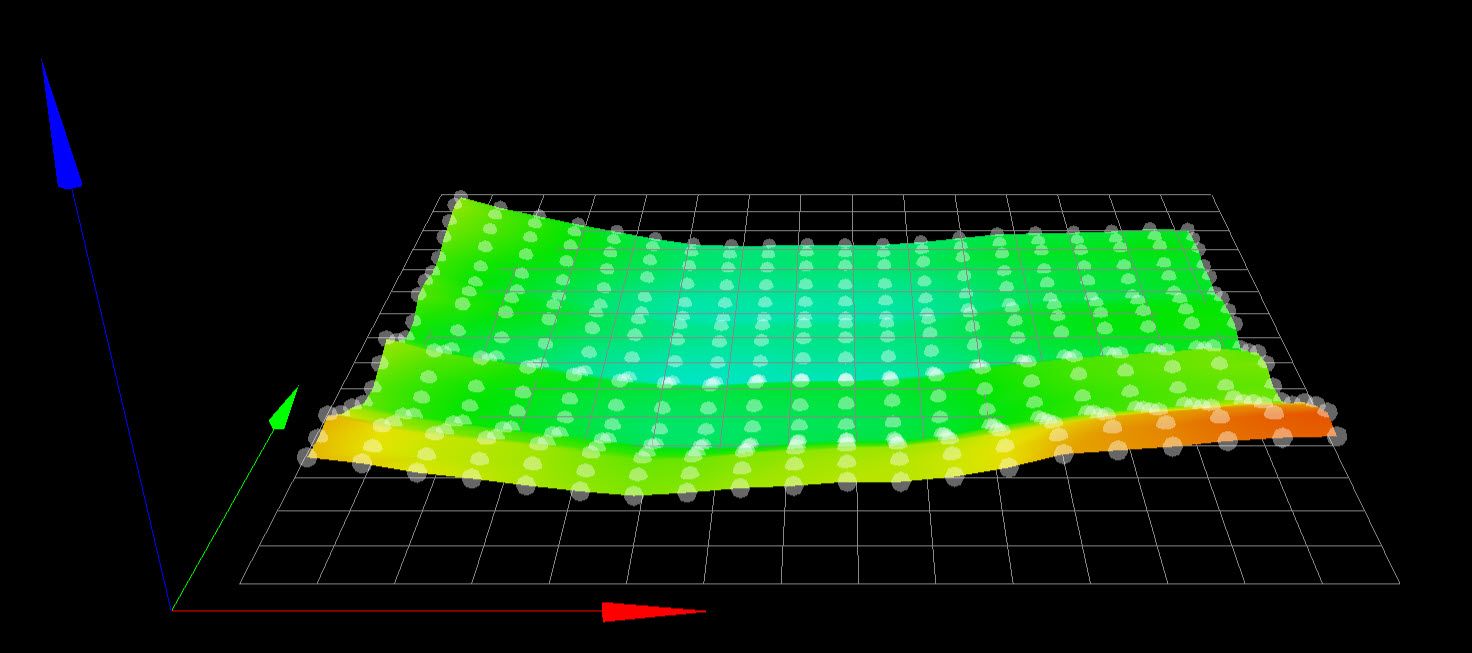

ok i had done the neeed config and have leveled it. after several leveling, best i could do was about 0,03mm to adjust.then i had done a G29 and heres the height map:

Any idears?

-

I have four different printers all with cast aluminum tool plate for the bed and they all are different.

I haven't taken the time to find out why as they all print ok.

-

Ok, I also have a casted aluminium plate which is on both sides milled. I think my FR4 plate is the reason why it is so different. It’s a bit translucent.

Tomorrow I will give a try with the mesh.

-

@gip_86 said in differences between manual and automatic leveling:

Ok, I also have a casted aluminium plate which is on both sides milled. I think my FR4 plate is the reason why it is so different. It’s a bit translucent.

Tomorrow I will give a try with the mesh.

I would agree the FR4 is likely the issue.

Frederick

-

Yes but it’s a good Surface to print.

Could it help to decrease the probing points?

Or could it help to do a sanding of it?

-

@gip_86 said in differences between manual and automatic leveling:

Yes but it’s a good Surface to print.

I use a number of different print surfaces - all of the removable kind held in place by magnetic force.

I like being able to separately chose the bed heater, the bed material and the bed surface - the goal being to have the best combination of parts.

Could it help to decrease the probing points?

No, that would just hide the errors - to get the best results from using mesh compensation you would increase the number of points

Or could it help to do a sanding of it?

The changes you see in the height map are actually quite small - sanding would likely make things worse.

-

@gip_86 as @fcwilt said, I'd increase the probing points a bit. That way you can look for obvious points that are wrong and manually change then in the .csv file

You could also use the A and S parameters in your

G31M558 to do repeated probing at different points to improve accuracy.Final point, my heightmap on my corexy is a lot worse than yours because my gantry sags a bit. However, I still get pretty good results with mesh compensation enabled so have not bothered to redesign it. Ultimately what matters is if you get good prints, not whether you have a perfectly flat heightmap (though we'd all love that!

)

)Edit: corrected reference to M558

-

@engikeneer said in

You could also use the A and S parameters in your G31 to do repeated probing at different points to improve accuracy.

I can't see in the Gcode dictionary the A option in the G31 command. How it works?

G31: Set or Report Current Probe status Usage G31 Pnnn Xnnn Ynnn Znnn Cnnn SnnnI'd like to get two/three probes in each probe point having a median to improve the probe accuracy.

-

@marcossf apologies, its M558 where you specify the A & S parameters for repeated probing... Will update my post

-

@engikeneer Ok, thanks. I'll try M558 A option.

-

so after several days of trying to get good results i have decided to unmount the IR Probe. It make no sense with my FR4 Plate.

does Anyone have ga good magnetic plate which will work with the IR sensor??

Bed temp could be 90 degree maxThank you

-

@gip_86 I visited the IR-probe category, because I have made a magnetic flexplate with 1mm pertinax (phenol resin). It came sanded on one side from the vendor and because it's darker and opaque than FR4 it triggers the IR sensor well.

I had issues at first, because I powered the probe from 5V. With 3.3V it's much better.

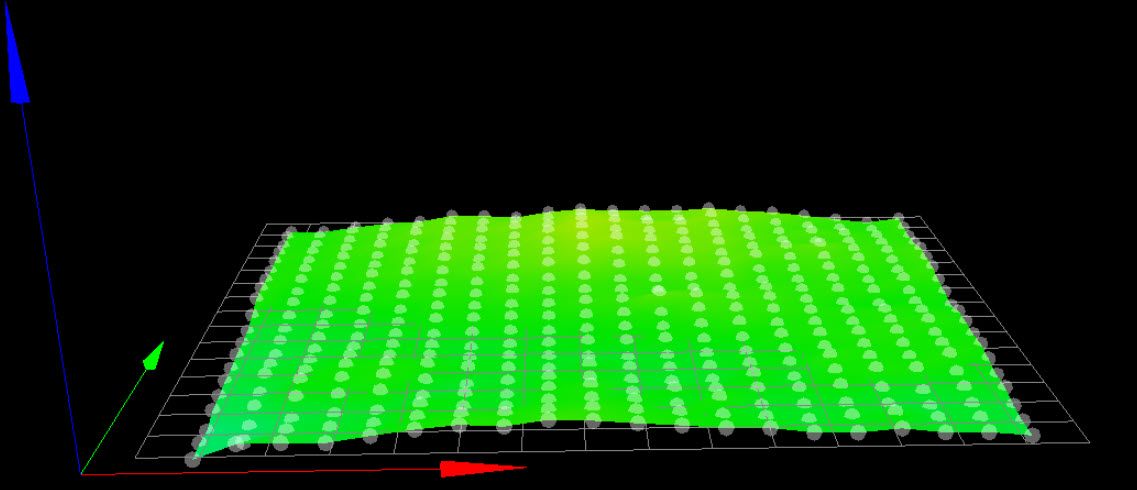

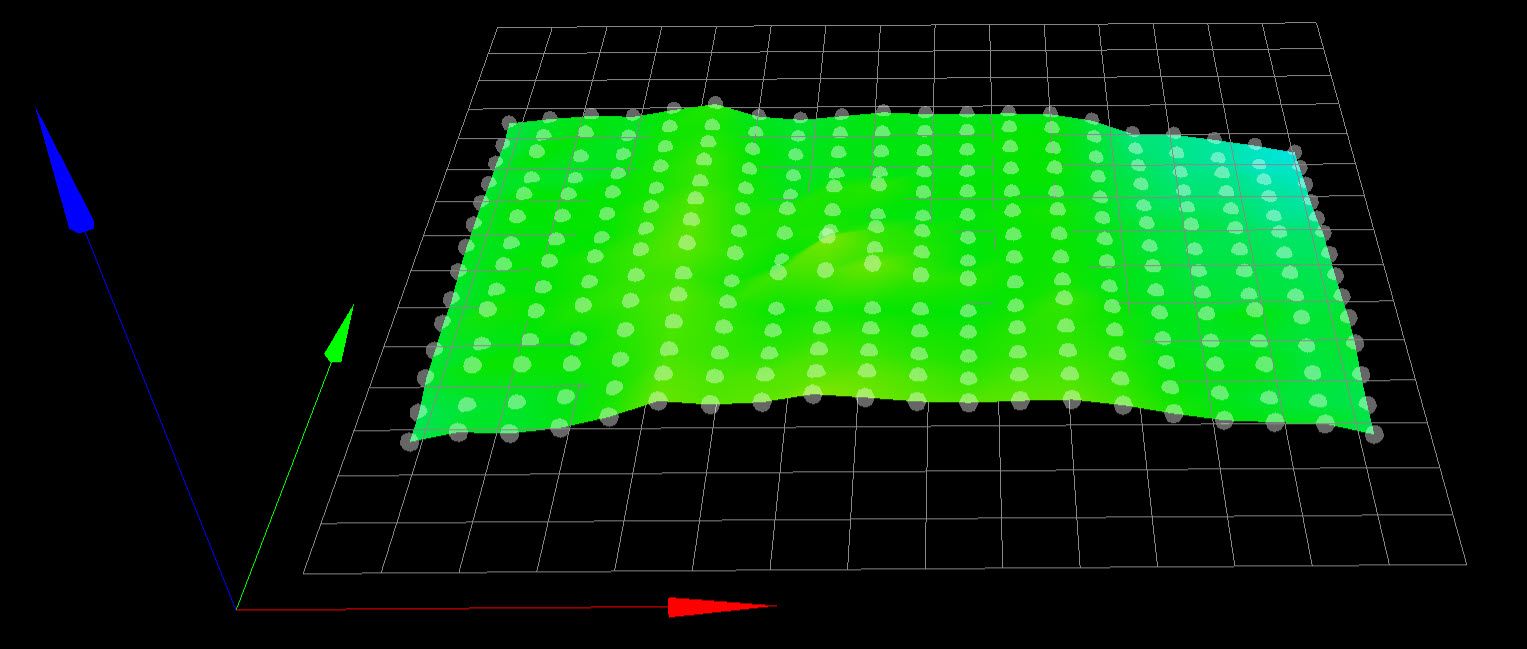

Still my heightmaps look horrible, even when I remove the pertinax and probe the magnetic sheet instead.

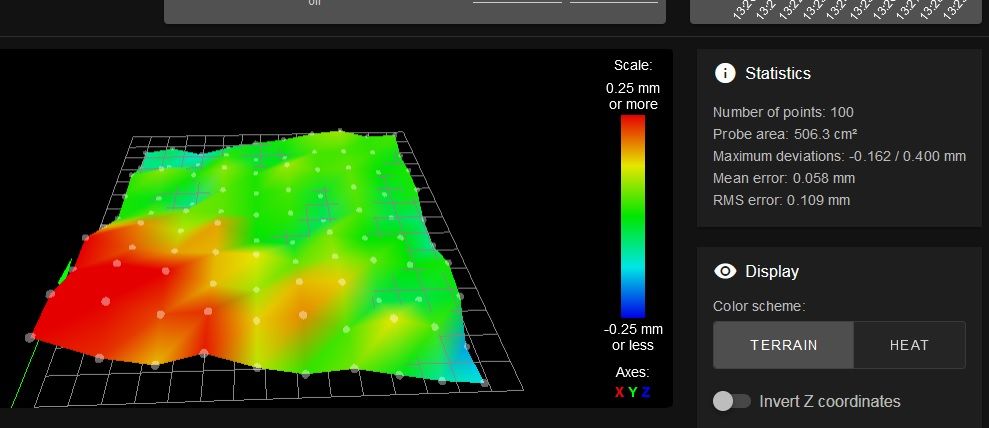

Pertinax

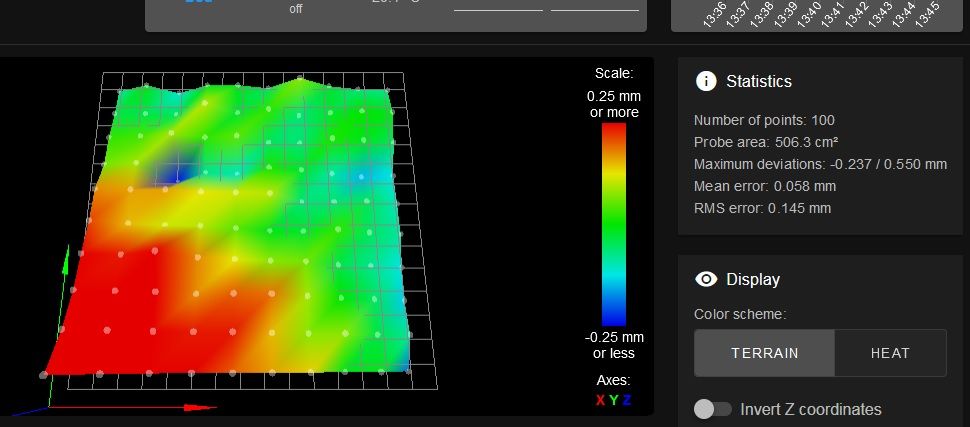

Mag-sheet only (with a glitch!, surface too shiny?)

So it's either a not so flat mag-sheet (bought from a site for magnetic car advertising)

or the cast aluminum plate is bent...