Pressure advance tuning with conditional G-code

-

ok so with perl:

; Make an inventory of axes that haven't yet been homed var axes = "" echo "Total number of axes: " ^ {#move.axes} while {iterations < #move.axes} if {!move.axes[iterations].homed} set var.axes = {var.axes ^ move.axes[iterations].letter} ; Home applicable axes echo "Axes to be homed: " ^ var.axes G28 {var.axes}without perl

; Make an inventory of axes that haven't yet been homed var axes = "" echo "Total number of axes: " ^ {#move.axes} while {iterations < #move.axes} if {!move.axes[iterations].homed} set var.axes = {var.axes ^ move.axes[iterations].letter} ; Home applicable axes echo "Axes to be homed: " ^ var.axes G28 {var.axes} -

so i can't recreate it with that snippet is if use no specified syntax highlighting.

-

@t3p3tony Editing on my phone is terrible because I can't get out of preview mode anymore, but I've managed to put the entire code in a code block without specifying any language, and changed line 100 to use "haven't". Then on line 106, 110, 114 and 117, I'm spotting some issues.

; This macro generates a test print to determine the best pressure advance factor (M572 S-parameter) ; It uses the test print described in this forum post: ; https://forum.duet3d.com/topic/6698/pressure-advance-calibration ; Author: Schmart ; WARNING: all dimensions, size units and speeds are in mm and mm/s ; Reference for conditional G-code: ; - https://duet3d.dozuki.com/Wiki/GCode_Meta_Commands ; Wishes for conditional G-code: ; - Canceling or stopping running conditional G-code ; - Simulation; logging what commands would be executed/generated without actually executing them ; - Dumping the variables (names and values) in a macro, perhaps also treating variable in a meta-way, e.g. {#var} for count, {var[0].name} and {var['layer_height'].value} ; - Assigning an object or array to a variable. E.g. var axis = move.axes[0]; echo {var.axis.letter} ; - Custom subroutine/function definition, e.g. def print_line(var a, var b) ; - ceiling(), pow() and sq() functions ; TODO: ; - Many optimizations still remaining ; - Perhaps the most important variables (bed and print temperature, filament diameter, extrusion multiplier, PA stepping) ; can be made into macro parameters, e.g. M98 P"0:/macros/4 - Print Tuning/Pressure Advance" B40 P204 D1.75 X0.95 S0.02 P0.002 ; Starting value for pressure advance var pa_start = 0.0 ; Pressure advance increment for each (whole) millimeter print height ; e.g. if var.height = 20, var.pa_start = 0.1 and var.pa_stepping = 0.004, then ; the PA test range is from 0.1 to (0.1 + 20 * 0.004) => 0.1 to 0.18. var pa_stepping = 0.01 ; The extruder to apply the pressure advance factor to var pa_extruder = 0 ; These values specify the center of the print bed ; The default bed center is at (0,0) var x_center = 0 var y_center = 0 ; Print temperatures var print_temperature = 205 var standby_temperature = 120 var bed_temperature = 40 ; Height of the test print var height = 20 var layer_height = 0.20 ; Number of fast segments var fast_segments = 3 ; Slow segments are at the beginning and the end, and in between fast segments, e.g. SLOW FAST SLOW FAST SLOW var slow_segment_length = 10 var fast_segment_length = 20 ; Definition of speeds var first_layer_speed = 20 var travel_speed = 80 var fast_segment_speed = 60 var slow_segment_speed = 10 ; Number of perimeters around the object as a stable base var skirt_loops = 6 ; Height of the skirt in layers var skirt_layers = 2 ; The tool number to print with var tool_number = 0 ; Extrusion width is calculated here, but can also be set with a literal value ; Note that 1.05 and 1.125 are common factors that result in 0.42mm or 0.45mm width respectively var nozzle_bore_diameter = 0.40 var extrusion_width = {var.nozzle_bore_diameter * 1.125} var filament_diameter = 1.78 var extrusion_multiplier = 0.93 ; Firmware retraction settings var retract_length = 0.5 var retract_restart_length = 0 var retract_speed = 40 var deretract_speed = 40 var retract_z_lift = 0 ; Flow math var filament_flow = {pi * var.filament_diameter * var.filament_diameter / 4} var regular_flow = {(var.extrusion_width - var.layer_height) * var.layer_height + pi * var.layer_height * var.layer_height / 4} var bridge_flow = {pi * var.nozzle_bore_diameter * var.nozzle_bore_diameter / 4} var line_spacing = {var.extrusion_width - var.layer_height * (1 - pi / 4)} var regular_flow_ratio = { var.extrusion_multiplier * var.regular_flow / var.filament_flow} var purge_line_flow_ratio = { 2.0 * var.regular_flow_ratio } echo "extrusion_width: " ^ var.extrusion_width echo "layer_height: " ^ var.layer_height echo "filament_flow: " ^ var.filament_flow echo "bridge_flow: " ^ var.bridge_flow echo "regular_flow: " ^ var.regular_flow echo "line_spacing: " ^ var.line_spacing echo "regular_flow_ratio: " ^ var.regular_flow_ratio ;M37 S1 ; Enter simulation mode ; Set firmware retraction M207 S{var.retract_length} R{var.retract_restart_length} F{60 * var.retract_speed} T{60 * var.deretract_speed} Z{var.retract_z_lift} T{var.tool_number} ; Select tool M106 S0 ; Turn off part cooling fan M568 P{var.tool_number} S{var.print_temperature} R{var.standby_temperature} A1 ; Set tool to standby temperature M190 S{var.bed_temperature} ; Wait for bed temperature to reach setpoint M116 P{var.tool_number} ; Wait for temperatures associated with the selected tool to be reached ; Make an inventory of axes that haven't yet been homed var axes = "" echo "Total number of axes: " ^ {#move.axes} while {iterations < #move.axes} if {!move.axes[iterations].homed} set var.axes = {var.axes ^ move.axes[iterations].letter} ; Home applicable axes echo "Axes to be homed: " ^ var.axes G28 {var.axes} ;G28 XYZ ; Home the X, Y and Z axes ;G28 XY ; Home the X and Y axes ;G28 Z ; Home the Z axis G21 ; Set units to millimeters M83 ; Use relative distances for extrusion ; Calculate object width var width = {var.fast_segments * var.fast_segment_length + (1 + var.fast_segments) * var.slow_segment_length} ; Calculate starting coordinates and other constant(s) var x_start = {var.x_center - 0.5 * var.width + var.skirt_loops * var.line_spacing} var y_start = {var.y_center - 0.5 * var.line_spacing + var.skirt_loops * var.line_spacing} var travel_feedrate = {60 * var.travel_speed} var first_layer_feedrate = {60 * var.first_layer_speed} ; Absolute position for purge line in X and Y space, 50 mm behind model G90 ; Use absolute coordinates G1 X{var.x_start} Y{var.y_start + 50} F{var.travel_feedrate} ; Set heater to final temperature and wait M568 A2 M116 P{var.tool_number} ; Absolute position of nozzle at first layer height G1 Z{var.layer_height} F{var.travel_feedrate} ; Relatively print two fat purge lines G91 ; Switch to relative coordinates G1 X{var.width} E{var.width * var.purge_line_flow_ratio} F{var.first_layer_feedrate} G1 Y{-(2 * var.line_spacing)} F{var.travel_feedrate} G1 X{-var.width} E{var.width * var.purge_line_flow_ratio} F{var.first_layer_feedrate} G10 ; Retract to prevent oozing ; Move to the start of the model in X, Y and Z space ; The skirt code also moves to the start, but the skirt can be disabled. ; Also, the skirt code does not set Z, and there may be no purge line for which Z is set. Safety first. G90 ; Use absolute coordinates G1 X{var.x_start} Y{var.y_start} Z{var.layer_height} F{var.travel_feedrate} G91 ; Switch to relative coordinates G11 ; Advance/unretract/deretract in preparation to print ; Routine for printing the test object var layers = {floor(var.height / var.layer_height)} echo "Total number of layers: " ^ var.layers while {iterations < var.layers} ; Track current layer var layer = {iterations + 1} ; Current height in mm var z = {var.layer * var.layer_height} ; Calculate pressure advance factor var pa = {var.pa_start + floor(var.z) * var.pa_stepping} ; Set pressure advance M572 D{var.pa_extruder} S{var.pa} ; Output some statistics while printing echo "Layer " ^ iterations ^ " (" ^ {iterations + 1} ^ " of " ^ {var.layers} ^ " at " ^ {var.z} ^ "mm)" echo "Pressure advance: " ^ {var.pa} ; Pre-calculate feedrates for first layer and other layers var slow_segment_feedrate = {60 * (var.layer == 1 ? var.first_layer_speed : var.slow_segment_speed)} var fast_segment_feedrate = {60 * (var.layer == 1 ? var.first_layer_speed : var.fast_segment_speed)} ; Print skirt if {iterations < var.skirt_layers} G90 ; Use absolute coordinates ; Move to absolute XY start coordinates G1 X{var.x_start} Y{var.y_start} F{var.travel_feedrate} G91 ; Switch to relative coordinates ; Print all loops of the skirt while {iterations < var.skirt_loops} var skirt_loop = {var.skirt_loops - iterations} var x = {var.width + 2 * var.skirt_loop * var.line_spacing} var y = {var.line_spacing + 2 * var.skirt_loop * var.line_spacing} ; Print one full skirt loop while iterations < 2 var direction = {iterations == 0 ? 1 : -1} G1 X{var.direction * var.x} E{var.x * var.regular_flow_ratio} F{var.fast_segment_feedrate} G1 Y{var.direction * var.y} E{var.y * var.regular_flow_ratio} F{var.fast_segment_feedrate} ; Travel to the start of the next skirt loop G1 X{var.line_spacing} Y{var.line_spacing} F{var.travel_feedrate} ; Print two perimeters back and forth of alternating slow and fast segments while iterations < 2 var direction = {iterations == 0 ? 1 : -1} ; Slow starting segment (X) G1 X{var.direction * var.slow_segment_length} E{var.slow_segment_length * var.regular_flow_ratio} F{var.slow_segment_feedrate} ; Remaining fast and slow segments (X) while iterations < var.fast_segments G1 X{var.direction * var.fast_segment_length} E{var.fast_segment_length * var.regular_flow_ratio} F{var.fast_segment_feedrate} G1 X{var.direction * var.slow_segment_length} E{var.slow_segment_length * var.regular_flow_ratio} F{var.slow_segment_feedrate} ; Print the side perimeter (Y) G1 Y{var.direction * var.line_spacing} E{var.line_spacing * var.regular_flow_ratio} F{var.slow_segment_feedrate} ; Move one layer up G1 Z{var.layer_height} F{var.travel_feedrate} G10 ; Retract G91 ; Relative positioning G1 F3000 Z20 ; Move gantry up 20mm G90 ; Absolute positioning G28 X ; Home X axis ;M104 S0 ; Turn off nozzle heat block M568 P{var.tool_number} S0 R0 A2 ; Set required heater temperature off M140 S0 ; Turn off bed M106 S0 ; Turn off part cooling fan M18 ; Disable stepper motors ;M37 S0 ; Leave simulation mode -

@schmart ok thanks. its obviously dependent on both the syntax used and the other lines.

-

The forum highlighting problem is long standing

https://forum.duet3d.com/post/225020

.

Sometimes you need yo try a few different language formats to get one that works.

Try python, bash, Java, json, pascal etc -

Hi. I test this today but I become with the duet3 6c Board and tool board 1lc in sbc Modus a error.

What can I Do?

I have test it with .g and .gcode and as MacroWith macro I become a another error Code

-

I wanted to try the code as well, and it doesn't seem to work as expected. The nozzle and bed heat up, and then the heater is turned off again as it starts printing it seems.

-

@heartleander81 As far as I know, the conditional G-code works in a macro only, not in a .gcode file.

The second problem I suspect is a copy error. Conditional G-code is indentation sensitive; with indented text (consistently using either spaces or tabs) you essentially define the sections that run conditionally or in a loop.

In other errors I spot that the word line in

purge_line_flow_ratiowas somehow replaced with the line numbers 139 and 141 the variable is used on, so perhaps something's going wrong in the process of copying the text from the forum post into the macro editor.I've just copied the code from the first post again in my editor (VS Code) and performed a difference/diff/compare with the code in my actual printer to verify that the code in this post is sound. There's no differences that explain what I'm seeing on your end

-

@izeman I'm missing text like 'Axes to be homed' in the console, so I'm assuming you had to modify the code for the topology of your printer.

Can you verify that the code still contains the

T{var.tool_number}andM568 P{var.tool_number} S{var.print_temperature} R{var.standby_temperature} A1statements? This selects the current tool, respectively sets the active and standby temperatures and requests to go to the standby temperature.If that's still in there, according to the documentation, the

M568 A2on line 131 should use the current tool (which should be selected withT{var.tool_number}) and thereforeM568should not require thePparameter, but you can try if changing the codeM568 A2(originally on line 131) toM568 P{var.tool_number} A2helps mitigate the error. -

@schmart hi.

When I write a echo for purge_line_flow_ratio become I the error on line 88 not in line 139 and line 141.

I have check it on vs code to and notepad ++ ther looks All good but doun't work -

Via privat chat @Heartleander81 and I tried to solve his problem.

He is using a D3 with SBC. I am using a D3M+ standalone. I sent him my macro and he tried to simulatet it. He got this error:

GetFileInfo: Cannot convert Z parameter to float (value {var.layer_height})We both are running 3.4 B5. Could this be a DSF Problem?

@oozeBot i know you have some printer running D3 with SBC. Can you try to simulate it?

Best

-

I have copy second time the Code from first comment.

I have the error with the line 139 and 141 but the test run now.

-

@pcr Can you please send me the full G-code file?

-

@chrishamm here ya goPA.g

-

Here is the console output. This was tested on a 6HC with attached SBC running 3.4b5.

After simulation:

M37 P"0:/gcodes/1636019653286-pa.g" Error: Operation failed (Reason: ArgumentException in SimpleCode: Cannot convert Z parameter to float (value {var.layer_height}))After upload:

Failed to get file info for 1636019653286-pa.g Operation failed (Reason: ArgumentException in GetFileInfo: Cannot convert Z parameter to float (value {var.layer_height})) -

Am I correct that the SBC scans the file and since it does not find a clear layer height, the error is there? Is only a guess, since without sbc the error is apparently not there

The test run now at my printer with the 2 error line 139 and 141. Nice work.

-

@heartleander81 said in Pressure advance tuning with conditional G-code:

Am I correct that the SBC scans the file and since it does not find a clear layer height, the error is there? Is only a guess, since without sbc the error is apparently not there

Well, it does indeed seem the handling is different compared to running the G-code on a standalone board. Please run the following macro, first with

M37and then withM98. Make sure you've homed the Z-axis yourself, and/or adjust the macro to suit your printer.var z = 25.0 G1 Z{var.z} F600I think that if this small snippet fails, we should follow up with one of the developers.

I've also run the code posted by @PCR on my printer as well, with

M37,M32andM98. The only thing that was noticeably different, were some printer-specific adjustments he made, and lines ending with \x0A\x0A (LFLF) characters, while mine uses \x0D\x0A (CRLF). So this code should run fine.The test run now at my printer with the 2 error line 139 and 141. Nice work.

So you're still seeing the weird 'purge_139_flow_ratio' and 'purge_141_flow_ratio' errors? These kind of errors are triggered when a variable is not defined. I can't explain the cause of that. But it seems that the word 'line' in the variable name

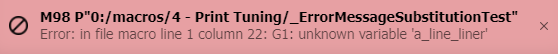

purge_line_flow_ratiogets substituted with the named constant called 'line' in the firmware part that prepares macro error messages. That also shouldn't happen.I can't reproduce this with my firmware build, and I haven't yet tested with an older firmware. Can you check what the following macro yields?

G1 X{var.a_line_liner} F600On my printer this results in the following expected error message. It doesn't say unknown variable 'a_1_liner' or unknown variable 'a_1_1r' or something like that:

Furthermore, can you run the macro(s) without the SBC (don't know if that's possible with your setup) and/or share what

M122returns? -

@heartleander81 About variables and this script running on a SBC, the documentation does still state that "These are supported in RRF 3.3 running in standalone mode". I'm not sure if this still applies, but it might explain your problems.

-

@izeman said in Pressure advance tuning with conditional G-code:

I wanted to try the code as well, and it doesn't seem to work as expected. The nozzle and bed heat up, and then the heater is turned off again as it starts printing it seems.

I came across this fix in the release notes for RepRapFirmware 3.4.0beta3:

M568 did not allow the P parameter to be omitted

So that explains that!

-

@schmart said in Pressure advance tuning with conditional G-code:

@izeman I'm missing text like 'Axes to be homed' in the console, so I'm assuming you had to modify the code for the topology of your printer.

Yes. Thanks. I inserted my G32 & G29 S1. All axes are homed.

And I now just have to correct the M568 command, as I'm running 3.3 still. And then we'll see