An "hardware" advice for linear rails

-

@sonderzug said in An "hardware" advice for linear rails:

Another thing worth mentioning, especially cheaper linear rails might not be 100 % stiff, so adding a second rail will greatly limit tilting around the longitudinal axis of the linear rail. Just make sure to make the mounting of the second linear bearing adjustible in both directions, because you might introduce binding forces otherwise.

Another consideration is that the mass of two stepper motors hanging off one side of the rail will cause torsional oscillations of the rail and its support when the rail moves in the Y direction. This is very noticeable with Hemera tools and accelerometer on the E3D tool changer - and they have just one stepper motor, not two. So increasing the stiffness of the beam by whatever means would be a good thing.

-

@deckingman, no, I don't mean 6988 x 10^-12. I specified units, but if you want to characterise distinguishing between a metre and a millimetre as being pedantic, feel free.

I'm not really sure what your point is - even after you corrected your initial factor of ten mistake I believe you're still out by a large factor primarily due to picking an unrealistic span. I think my value was a realistic span, and I provided my justification for it. Your defence of your calculation seems to be to argue that I should have used 6.867 rather than 7? When the original spec was "about 700g"?

There's bigger approximations than that in my working, despite which, I remain of the opinion that my estimate of 0.03mm is closer to reality than your ten times higher value.

-

@gixxerfast said in An "hardware" advice for linear rails:

As you probably already know the Voron 2 still has (it's changing) two MGN9H rails.

A data point regarding the Voron new single MGN12 design. The recommendation is to get a rail that has 'medium preload'. That's slightly tighter than the standard ones.

Has for the two MGN9 design, people complained that it creates a twist or distortion with temperature changes. I can't confirm that from personal experience.

-

@zapta Yes, on my V2.4 I have the single Hiwin MGN12H with Z1 preload which I feel was a big improvement. My Z-offset movement and bed mesh caused by heat was significantly improved.

I now also have the Ti-backers but they are mostly bling IMHO.

However, many still have the dual MGN9H setup and seem to be happy with that.

-

@achrn A perfect personification of why I don't send much time helping others out on these forums any more..........Bye

-

@gixxerfast said in An "hardware" advice for linear rails:

However, many still have the dual MGN9H setup and seem to be happy with that.

Titanium backers, wow!

https://www.fabreeko.com/products/v2-4-trident-titanium-extrusion-backers

https://www.fabreeko.com/products/v2-4-trident-titanium-extrusion-backersI think that the direction is to move to a single MGN12. The Trident (latest design) uses it and IIRC the upcoming ClockWorks 2 extruder will required it. It also simplifies the design, single rail and no seesaw underneath.

BTW, on the Voron, the extruder stepper (heaviest part) is located above the rail, rather than hanging on its side as the picture in the OP here suggests. May provide extra stability, though not sure how it handles Y acceleration as dc42 mentioned above.

-

@achrn said in An "hardware" advice for linear rails:

Deflection os a simply supported beam with point load at mid span is proportional to cube of span

One more reason for not building a 3D printer larger than one actually needs.

-

Guys thanks to everybody for the very precious advices! At the end I want to be more cautios as I can so I've decided to add another linear rail in the back of the 2020 extrusion. I'll loose about 2,5cm of Y space but for me is not a problem.

Thanks again!

-

@thedragonlord said in An "hardware" advice for linear rails:

Guys thanks to everybody for the very precious advices! At the end I want to be more cautios as I can so I've decided to add another linear rail in the back of the 2020 extrusion. I'll loose about 2,5cm of Y space but for me is not a problem.

Thanks again!

If the extra rail is just to increase stiffness, you could use a piece of flat steel or some such, which would save you some money. BTW, I never claimed that your rail would deflect by any amount because you didn't specify a length. I merely used a 1 metre length to keep the maths simple and illustrate the importance of doing the maths. I hope you saw through the pedantic criticism of my effort to help you.

-

@deckingman said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

Guys thanks to everybody for the very precious advices! At the end I want to be more cautios as I can so I've decided to add another linear rail in the back of the 2020 extrusion. I'll loose about 2,5cm of Y space but for me is not a problem.

Thanks again!

If the extra rail is just to increase stiffness, you could use a piece of flat steel or some such, which would save you some money. BTW, I never claimed that your rail would deflect by any amount because you didn't specify a length. I merely used a 1 metre length to keep the maths simple and illustrate the importance of doing the maths. I hope you saw through the pedantic criticism of my effort to help you.

I did! I really appreciated your help!

-

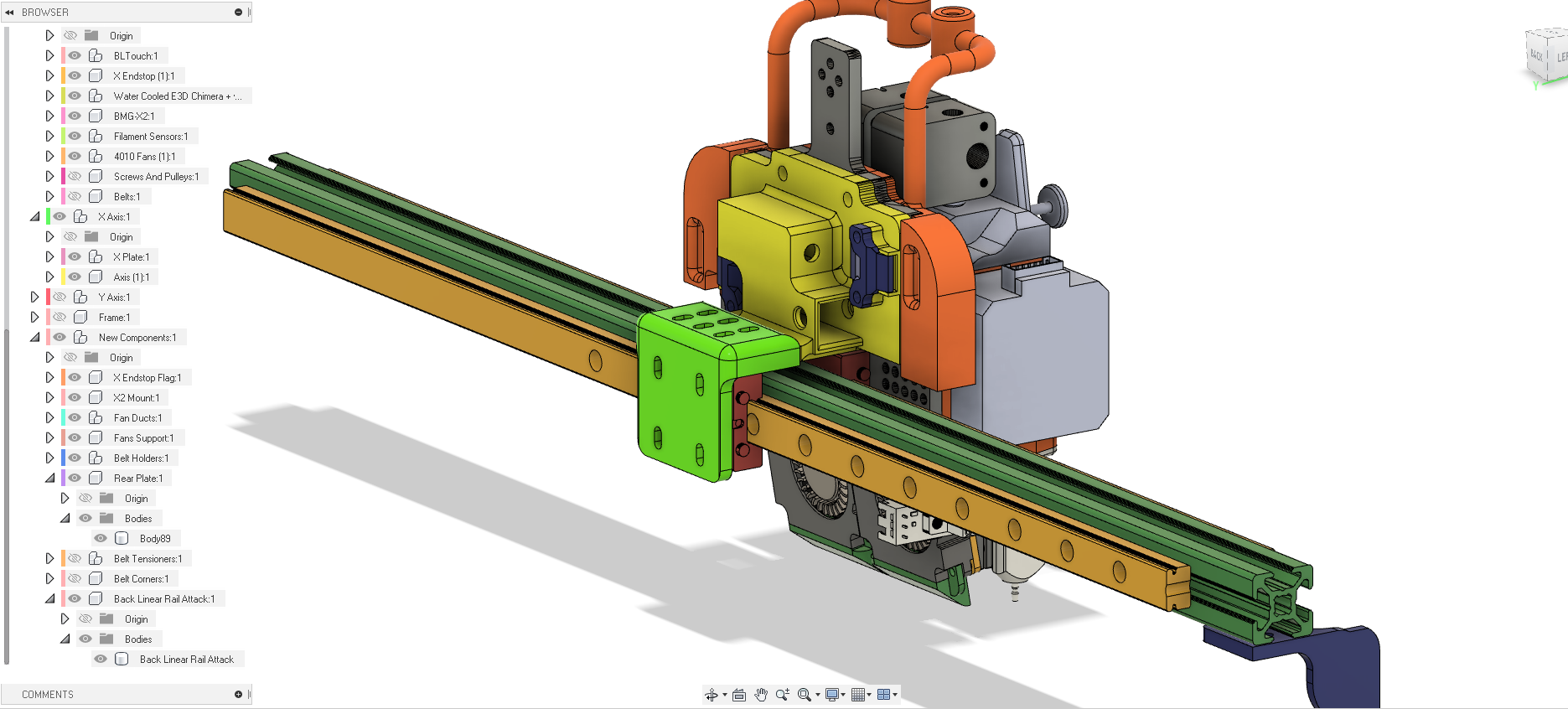

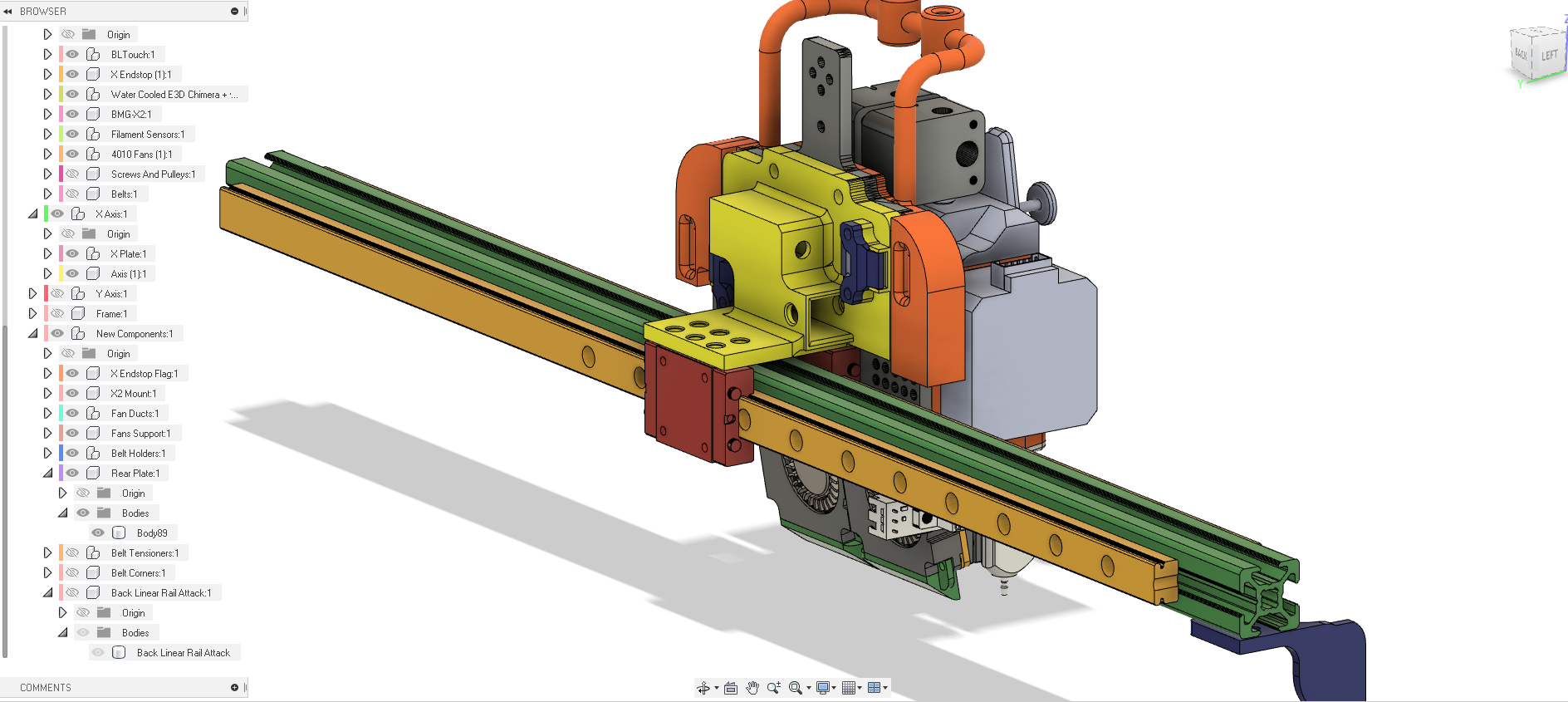

Here's the mod!

How about it?

Thanks!

-

@thedragonlord

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape) -

@o_lampe said in An "hardware" advice for linear rails:

@thedragonlord

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape)mmmmhh....I think you're right! I thing I'm going to take of tthe middle row of screws and add an u shape vertical "fin" in their palce...the thickness is already at 5,2mm....thanks!

-

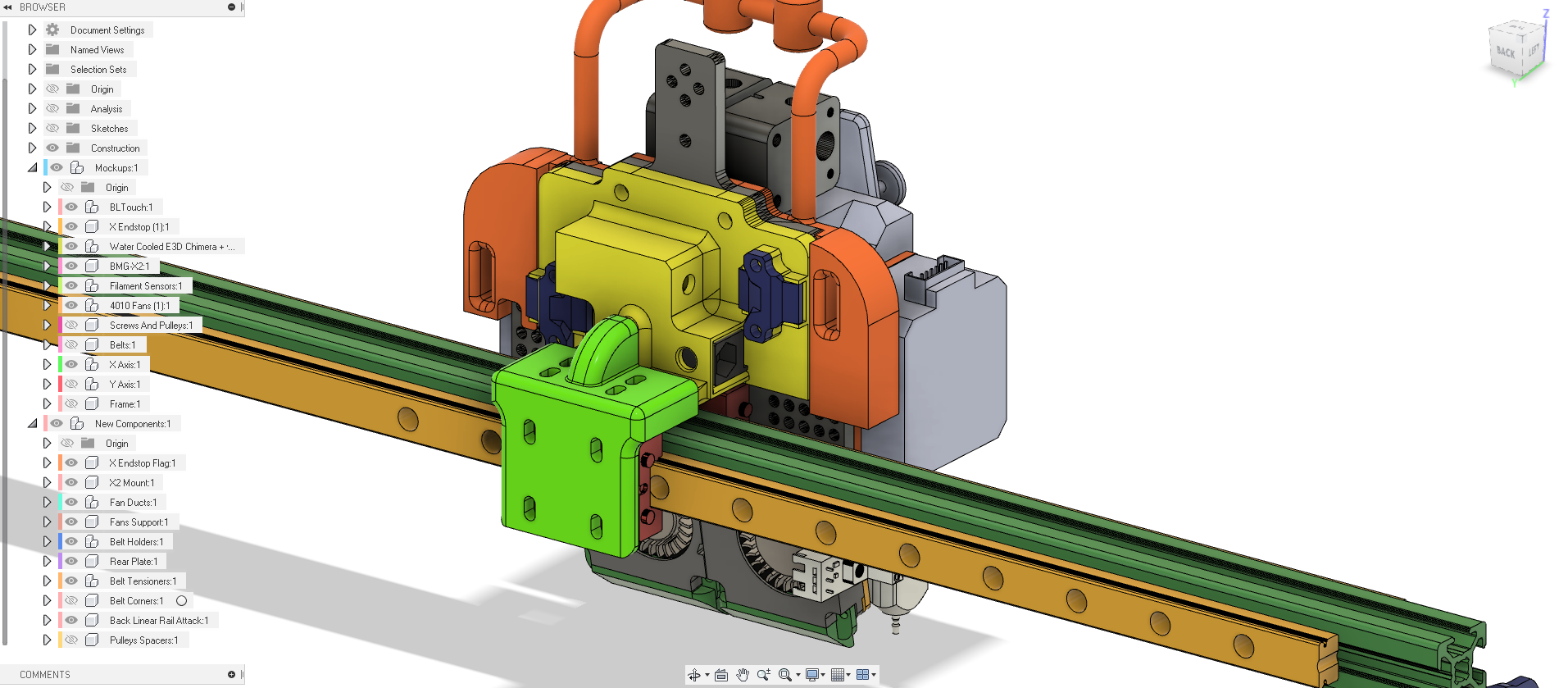

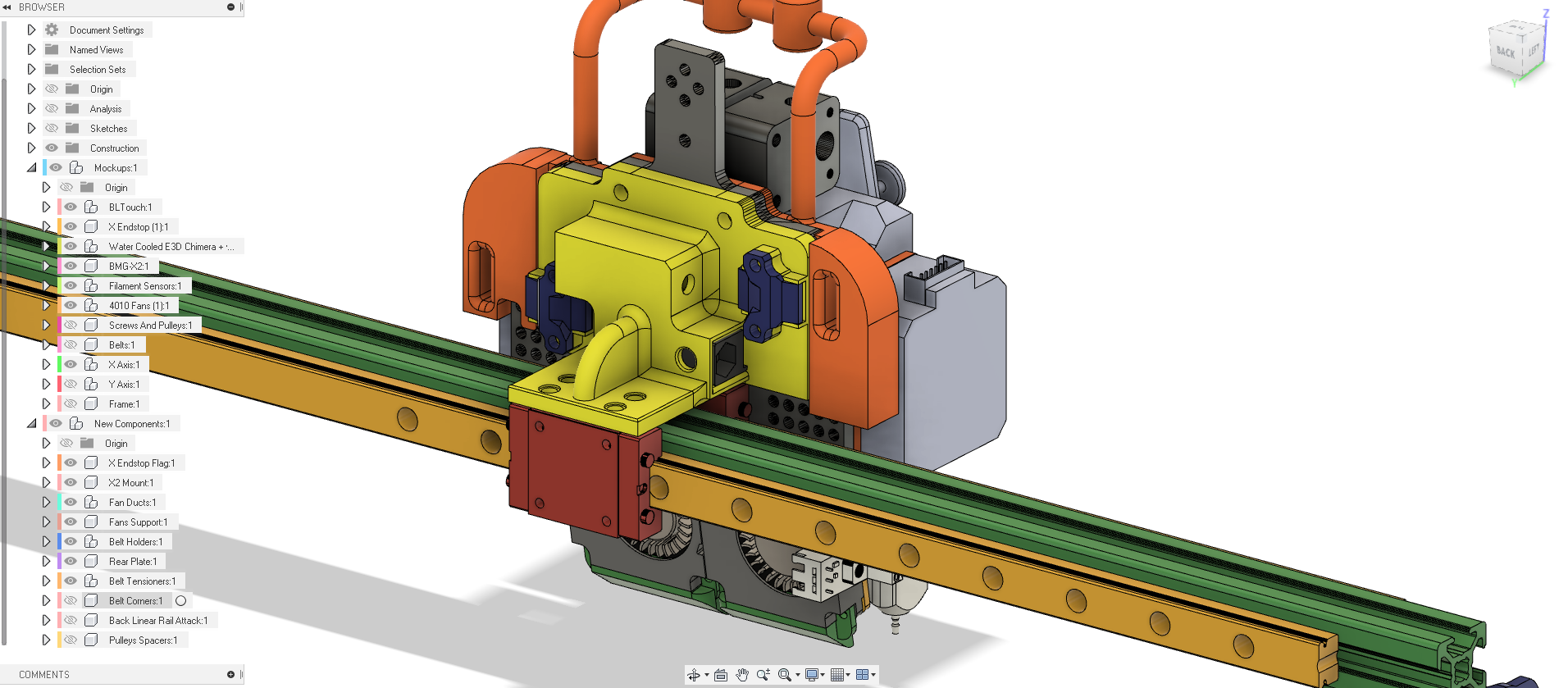

@o_lampe said in An "hardware" advice for linear rails:

@thedragonlord

The yellow tongue could be much thicker for my liking or have vertical struts (like an U-shape)better like this?:

-

@thedragonlord, now that you have two rails, you may want stepping back and rethinking the position of the parts and the load distribution. For example, moving the two motors (heave) on top of the rails. Just a thought.

-

@zapta said in An "hardware" advice for linear rails:

@thedragonlord, now that you have two rails, you may want stepping back and rethinking the position of the parts and the load distribution. For example, moving the two motors (heave) on top of the rails. Just a thought.

It's impossible, the X2 is a single piece

-

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

-

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

-

@thedragonlord said in An "hardware" advice for linear rails:

@zapta said in An "hardware" advice for linear rails:

@thedragonlord said in An "hardware" advice for linear rails:

It's impossible, the X2 is a single piece

You can also rethink the x2 choice.

no, I've already bought it

-

@phaedrux said in An "hardware" advice for linear rails:

Does that apply if he is happy with the X2 and wants to use it?

Frederick