Heater fault on heated bed because it's rising to slow.

-

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@siam said in Heater fault on heated bed because it's rising to slow.:

Short feedback from my side, the problem is not solved

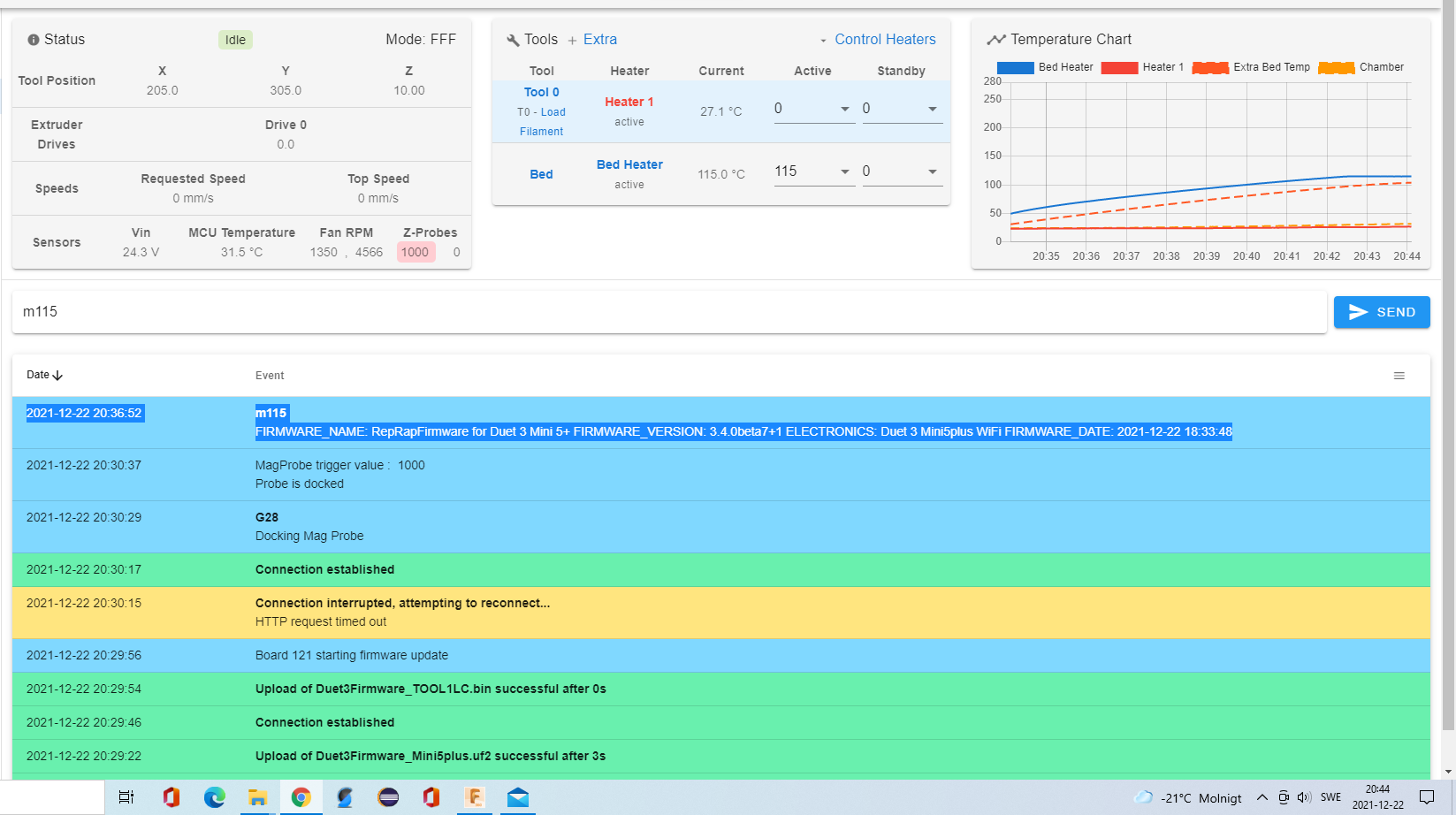

The Result from the pid tuning with RFF 3.4.b6:

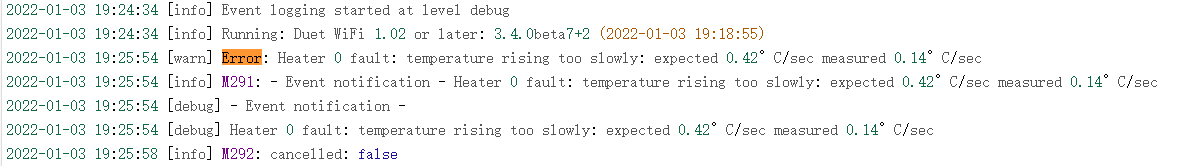

M307 H0 R0.460 C286.278:286.278 D0.90 S1.00 V24.3 B0 I0and the result from PID tuning with RRF 3.4.b7:

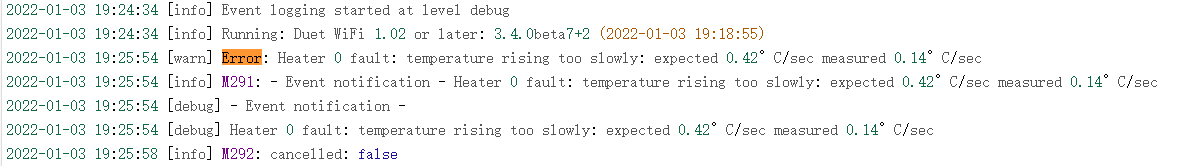

M307 H0 R0.484 K0.438:0.000 D0.85 E1.35 S1.00 B0and the error:

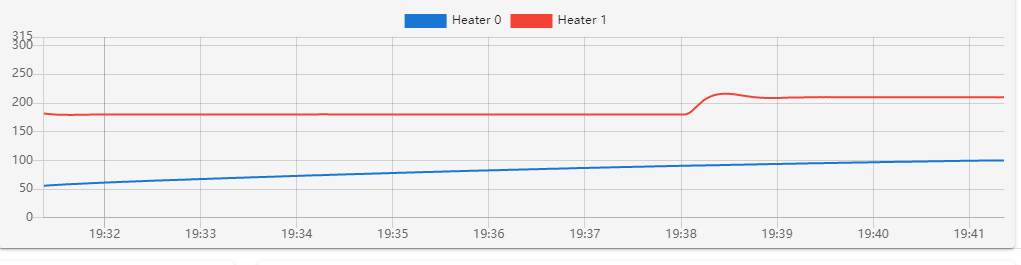

Error: Heater 0 fault: temperature rising too slowly: expected 0.43°C/sec measured 0.19°C/secPlease post the temperature plot while heating up the bed, to help me diagnose this.

Want to confirm that, the same printer with different firmware, such as rrf and klipper, no issue on klipper

-

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@siam said in Heater fault on heated bed because it's rising to slow.:

Short feedback from my side, the problem is not solved

The Result from the pid tuning with RFF 3.4.b6:

M307 H0 R0.460 C286.278:286.278 D0.90 S1.00 V24.3 B0 I0and the result from PID tuning with RRF 3.4.b7:

M307 H0 R0.484 K0.438:0.000 D0.85 E1.35 S1.00 B0and the error:

Error: Heater 0 fault: temperature rising too slowly: expected 0.43°C/sec measured 0.19°C/secPlease post the temperature plot while heating up the bed, to help me diagnose this.

For the bed heater case above, it is very normal that take 5~10mins to heat the bed from around 20°C to around 80°C, (80°C-20°C) / 0.19°C/sec /60sec/min=5.26min. So I think 'the quick factor' is good to apply to tools heater but not for bed heater.

-

@siam thanks for the video, that's really helpful.

What I suspect is happening is that your bed heater has a high thermal mass (e.g. aluminium plate) and the thermistor is embedded in the heater, not in good contact with the plate. Does that describe your bed heater? This makes the long-term heating behaviour very different from the short-term behaviour. The current tuning algorithm measures the short term behaviour, because that is what is required for computing suitable PID parameters.

Please can you do a video of the heater being tuned, so that I can see the complete temperature graph during the tuning process.

As a workaround until I have a solution, if you reduce the R parameter in the M307 command by 30%, that should be sufficient to avoid getting heater faults.

-

@siam @hestiahuang please try the firmware build at https://www.dropbox.com/sh/5ubjszy9fmlvzwu/AAAeOMGP-Yi-Gn9LZwQoPfita?dl=0.

-

@dc42 I wasn't addressed but I tried it anyway since I was having problems but with this version it heated up without any errors. Absolutely perfect. Before, with b7 I would have had three errors before reaching target temp. Thanks!

-

I also have this problem and noticed that the difference is double (or half) of what is expected.

tuning again and again did not change much, but it looks like you're already fixing the problem

I have a suggestion: could you add a feature that makes it possible to zoom in on the temperature chart (as in temporarily increase the window size or open in a new window)?

The way it currently is makes it impossible to see small changes, but I would be interested in seeing them.

I think it would make it possible to see changes when feeding too fast or having air flow etc -

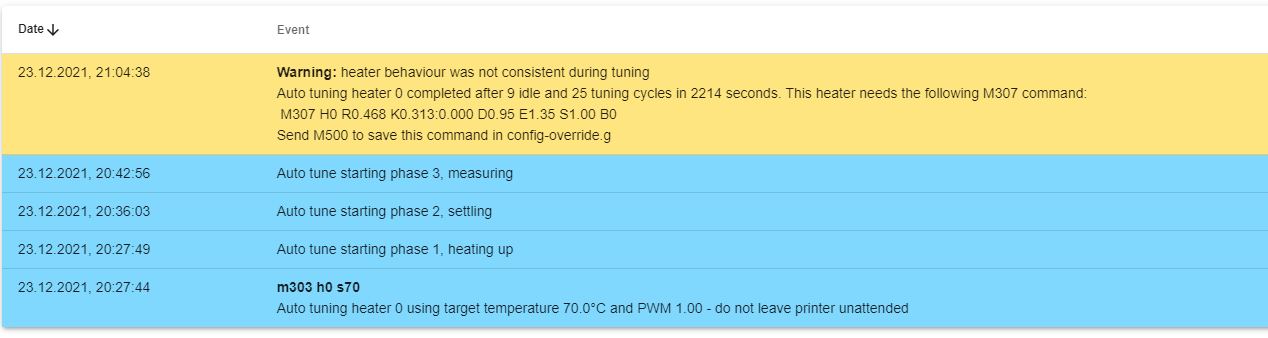

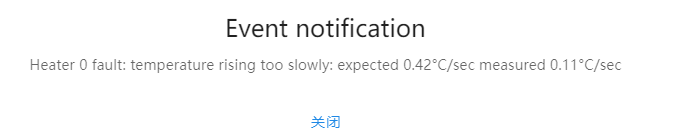

@dc42 I have tested the new firmware, thanks for this! Now the PID-Tuning takes a long time (over a half hour) and after this I get now a warning;

If I use this PID settings to heat up my bed, I still get the heater fault

Error: Heater 0 fault: temperature rising too slowly: expected 0.34°C/sec measured 0.11°C/secI have recorded the PID Tuning and you can view this long video under:

https://kleinersonnenschein.eu/video/pidtuning_3.4.b7+1.mp4

I hope this will help you when you need more tests then let me know

But first I wish you and the whole great duet team a merry Christmas, thanks for your hard work!

-

@siam Perhaps I've asked this before in another thread, but can you show/describe what your bed assembly is like?

-

I forget to answer your question

What I suspect is happening is that your bed heater has a high thermal mass (e.g. aluminium plate)

My Alu plate is 420 x 420 x 8 mm

and the thermistor is embedded in the heater,not in good contact with the plate.

yes it is

Does that describe your bed heater?

yes

As a workaround until I have a solution, if you reduce the R parameter in the M307 command by 30%, that should be sufficient to avoid getting heater faults.

I haven't test with 30% at the moment, I reduce it to 50% and this works for now

-

@phaedrux The structure of the heating plate is as follows :

First the Alu plate with 420 x420 x 8 mm

Then this silicone heatbed :

https://de.aliexpress.com/item/32612060131.html?spm=a2g0o.9042311.0.0.27424c4daTA4uh

With 220V / 500W

and under this I have a cork plate for isolation. -

undefined Exerqtor referenced this topic

undefined Exerqtor referenced this topic

-

undefined Exerqtor referenced this topic

undefined Exerqtor referenced this topic

-

This post is deleted! -

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@siam thanks for the video, that's really helpful.

What I suspect is happening is that your bed heater has a high thermal mass (e.g. aluminium plate) and the thermistor is embedded in the heater, not in good contact with the plate. Does that describe your bed heater? This makes the long-term heating behaviour very different from the short-term behaviour. The current tuning algorithm measures the short term behaviour, because that is what is required for computing suitable PID parameters.

Please can you do a video of the heater being tuned, so that I can see the complete temperature graph during the tuning process.

As a workaround until I have a solution, if you reduce the R parameter in the M307 command by 30%, that should be sufficient to avoid getting heater faults.

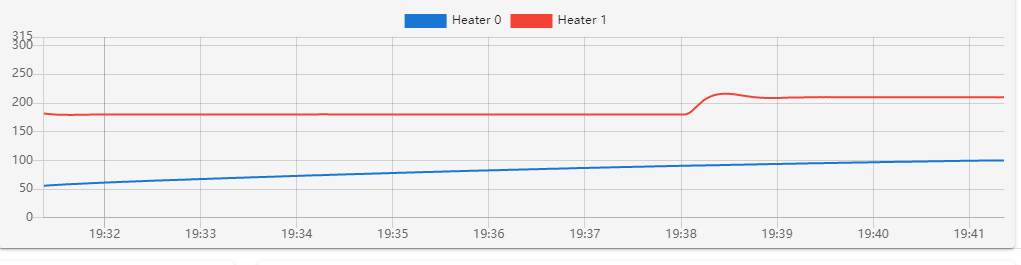

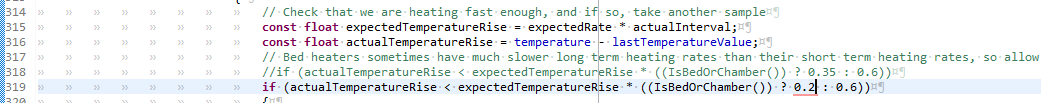

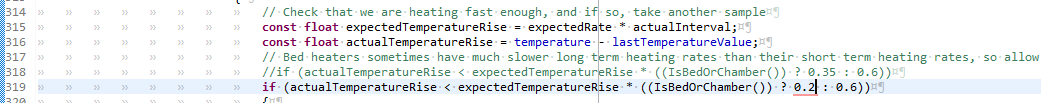

Tested beta7+2 today, issue is still on my printer. I read the code change and found there is some tuning, I still have to change to 0.2. From the heat chart, it needs to take more than 10 minutes to heat from 50°C to 100°C

-

@hestiahuang said in Heater fault on heated bed because it's rising to slow.:

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@siam thanks for the video, that's really helpful.

What I suspect is happening is that your bed heater has a high thermal mass (e.g. aluminium plate) and the thermistor is embedded in the heater, not in good contact with the plate. Does that describe your bed heater? This makes the long-term heating behaviour very different from the short-term behaviour. The current tuning algorithm measures the short term behaviour, because that is what is required for computing suitable PID parameters.

Please can you do a video of the heater being tuned, so that I can see the complete temperature graph during the tuning process.

As a workaround until I have a solution, if you reduce the R parameter in the M307 command by 30%, that should be sufficient to avoid getting heater faults.

Tested beta7+2 today, issue is still on my printer. I read the code change and found there is some tuning, I still have to change to 0.2. From the heat chart, it needs to take more than 10 minutes to heat from 50°C to 100°C

I don't have time to test and tune the parameter, just give 0.2 temporary

-

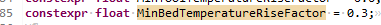

@hestiahuang if the expected heating rate is 0.42degC/sec and actual is 0.14 then any value below 0.14/0.42 = 0.333 should work. I'll change it to 0.3 in the next build.

-

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@hestiahuang if the expected heating rate is 0.42degC/sec and actual is 0.14 then any value below 0.14/0.42 = 0.333 should work. I'll change it to 0.3 in the next build.

Many thanks for your explanation. Suggest that we can keep some buffers.

-

@dc42 said in Heater fault on heated bed because it's rising to slow.:

@hestiahuang if the expected heating rate is 0.42degC/sec and actual is 0.14 then any value below 0.14/0.42 = 0.333 should work. I'll change it to 0.3 in the next build.

Tested base on today's version. Thank you very much! Seem 0.2 is better to me.

-

undefined gabrealek referenced this topic

undefined gabrealek referenced this topic