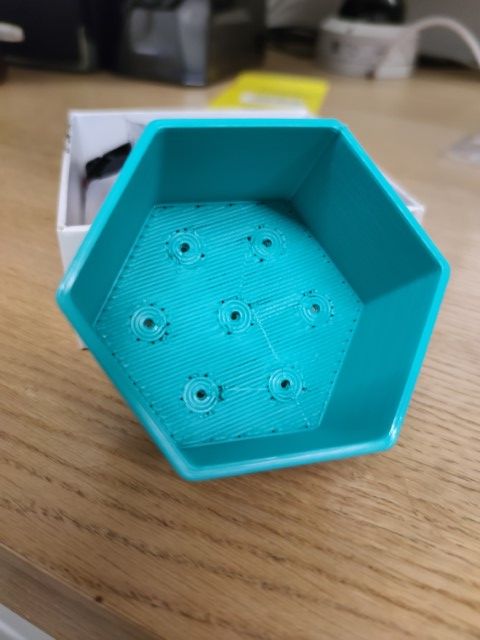

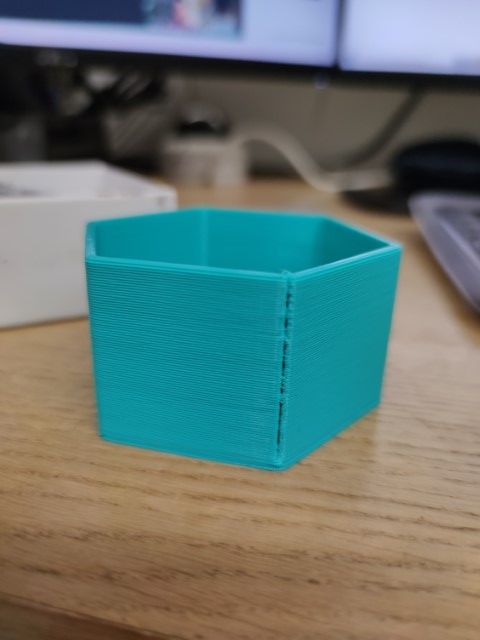

0.8 Nozzle not bad for the first try bt I need your help

-

Hi guys ,

I am trying a 0.8 nozzle for big print but I am having some problems of perimeter gaps.

Perimenter and internal gap are separated by abot 0.1mm space

Any idea how can solve this problem.My setting for this print

PLA

nozzle 0.8 vulcano

temperature 220

extrusion multiplier 1.02

extrusion width 1.0

layer eight 0.5

top solid layer 3

bottom solid layer 3

outline perimeter 3 -

Are you perhaps exceeding your hot end melt rate?

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s177

See the steps beginning here to find your max extrusion rate. Once you know the max extrusion rate you can find your max speed based on the height and width you want to use.

Also with larger nozzles you may need to increase the overlap setting and retune pressure advance and retraction.

-

I use 0.8 nozzle size too for large prints. I have this problem too but it seems that acceleration may be modified. Be careful with speed because extruder motor has to provide more speed for the print. So try to lower your print speed

-

@phaedrux Thank you I am in the range / max speed 50mm/s printing at 40 mm/s.

I am goiong to try overlapp seting and reducing the sped a bit -

@claustro Also, if you use pressure advance, disable it or set it to really low value. Any pressure build up that you might see with a 0.4mm nozzle will be much reduced with a 0.8mm nozzle.

-

Depending on your slicer you may increase infill overlap for the holes in the top layer, and tune Z seam settings for the gap at the seam.