Capricorn PTFE Tubing XS- Low Friction

-

I think somebody is making a good deal of money with this product.

I wonder if if can be purchased in bulk.

Still I would like to try it.

Frederick

-

It can be purchased in bulk, filastruder cuts to length ordered. It is pure raw ptfe and tight torrence production processes but yeah still overpriced but the results i have seen make it a necessary upgrade to any bowden system.

-

For a Rostock Max sized build with a Bondtech Extruder and the Capricon XS my settings for Simplify3D are copied below for reference. They seem to work pretty well with PLA. I have not had any jamming issues so far.

I reduced my retraction length by about 25% after installing the Capricorn tubing. I would guess at 25% - 50% reduction in your previous retraction distance should work pretty well.

[c]Retraction: 5.00mm

Extra Restart Distance: -0.50mm

Retraction Vertical Lift = 0.15mm

Retraction Speed: 100mm/s

Coasting Distance: 1.50mm

Wipe Distance: 2.00mm[/c] -

The towers and the Groot were both set to 60mm/s, but what the actual speed was would be impossible to say, since both have sections small enough that acceleration settings would slow things down somewhat. The arm that you see in the Groot photo is approximately the same diameter as the retraction towers, so we might assume that the nozzle reached similar speeds going around that arm as it did on the towers, though the towers have 90 degree corners and the arm doesn't.

I just ran some more towers where I went from 2 to 3 perimeters to see if the difference was simply down to how much actual printing got done between retractions (see if maybe on the towers the extruder/bowden/nozzle system hadn't reached its normal steady state pressure due to how little was printed between retractions and repriming). At 2.0mm retraction I got enough oozing to create the usual "hangers" sticking off the side of the tower at an angle. At 2.5mm there were little nubbins sticking out, and at 3.0 there were nearly but not quite nonexistent nubbins, and at 3.5mm retraction no sign of any oozing whatsoever.

I've got to go somewhere for a while, so I just started a Baby Groot with retraction set to 3.1mm. I'll see how it went when I get back.

If it works great, and continues to work for other types of prints with larger pieces, sharper corners, wider spaces, etc., then I'll know that for at least this filament the new retraction of 3.1mm is it. This is compared to 4.6mm with my previous cheapo PTFE.

While I was hoping to get it all the way down to 2mm, and thought I had with my original retraction tests, I'll say that 3.1mm from 4.6mm is a huge improvement. It means that the pressure "spring" inside the tubing from the filament kinking up and absorbing or releasing incoming filament feed rates is substantially reduced by using this tubing with its smaller diameter.

This filament (Hatchbox black PLA) measures out at only 1.72 to 1.73mm, unfortunately. If reducing the diameter of the PTFE tube is mostly responsible for reducing the bowden tube pressure spring, then it's probably also true that the closer in diameter you get from the filament to the ID of the PTFE tube, the better. I'd be better off with filament measuring 1.76 or 1.77 than 1.73.

Sounds like a small difference, but the bowden tube pressure spring effect is responsible for keeping filament flowing more than you want going into corners where the deceleration of the nozzle requires slowing down the filament flowrate to avoid blobbing, and not accelerating as fast it should coming out of corners (which results in thinning of the part coming out of the corners). If a difference of only .15mm inside diameter of the bowden tube can drop my retraction from 4.6 to 3.1mm, then .03mm difference in filament diameter is a bigger deal than you'd think.

Most of my filaments measure out at 1.75 or 1.76 or so. I'll have to figure out what filaments tend larger and buy more of that, and less of the stuff that measures smaller. I'm disappointed that this Hatchbox PLA measured out smaller like this. My Hatchbox PETG typically comes in at least 1.75mm.

Did this work on the groot?

-

I had a Groot printout working great with 3.1mm with only a few faint whisps of string until one of his arms broke for unrelated reasons (only 2 perimeter walls, low infill, and .35mm nozzle with .35mm line width, on a fairly thin arm, so it was pretty weak).

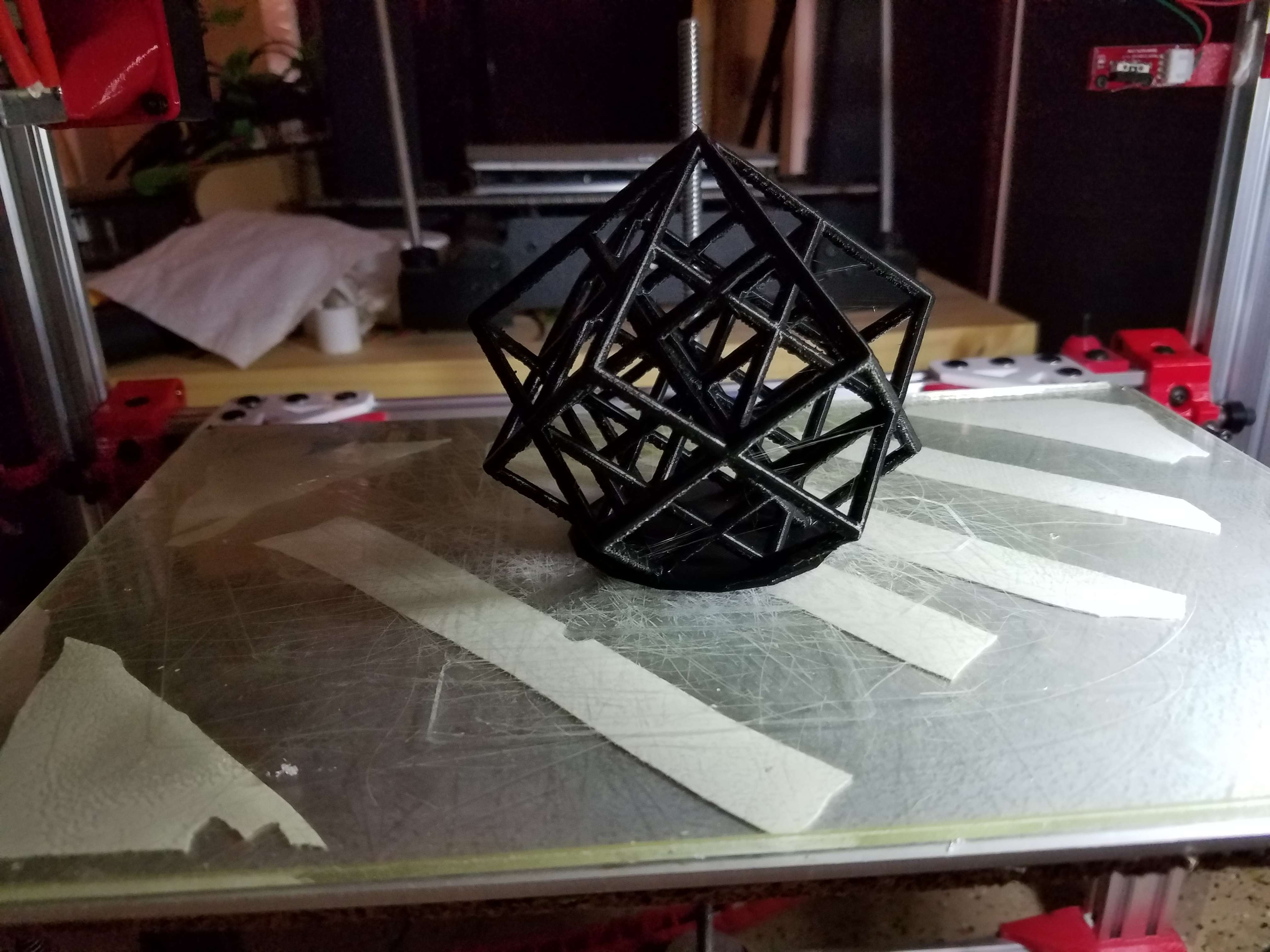

I did print out this geometric torture test thingy with it this morning. This was 3.2mm retraction, .35mm nozzle, .18mm layer height.

You can see a few very faint whisps of string. Given the challenge of printing this, I think that's pretty decent. With my normal PTFE tube I wouldn't have printed this with less than 4.5 or 4.6mm retraction. And this is with 1.71-1.72mm filament.

I haven't loaded the ASA filament again to try it out. It measures out at an even 1.75mm.

-

Wow. This stuff is amazing. I'm running TPU through a 2 foot bowden tube pushed by a Titan extruder and no problems at all.

-

I don't remember if these links have been posted on this forum. In case, you may find them usefull to calibrate retract with Bowden config:

https://airtripper.com/1320/airtripper-extruder-filament-force-sensor-announcement

https://airtripper.com/1338/airtripper-extruder-filament-force-sensor-introduction

https://airtripper.com/1473/airtripper-extruder-filament-force-sensor-design-3d-print

https://airtripper.com/1397/electronic-kitchen-scales-teardown-versus-load-cells

https://airtripper.com/1626/arduino-load-cell-circuit-sketch-for-calibration-testI will soon order this load cell:

-

If you need/want more than a meter of it, you can find it cheaper directly from Capricorn. They have a few bundle options too that come with a cutter and stickers.

I JUST bought some generic PTFE off of Amazon Prime. While it seems to have made a nice improvement over my worn out tube, I kinda wish I had remembered about this Capricorn stuff.

-

If you need/want more than a meter of it, you can find it cheaper directly from Capricorn. They have a few bundle options too that come with a cutter and stickers.

I JUST bought some generic PTFE off of Amazon Prime. While it seems to have made a nice improvement over my worn out tube, I kinda wish I had remembered about this Capricorn stuff.

I just ordered some direct from Capricorn, but based on the live Q&A Tom did with E3D they are about to become a UK reseller for it.

-

I just ordered 2 meters of the XS (the dark blue 1.9 or 1.8 ID) Capricorn tubing. I will try to report back once I receive and install it.

-

I've got both the XS and TL series. The supposedly smaller inner diameter of the XS series is actually slightly larger than the TL series, but I'm sure it's just a batch issue. Both the XS and TL tubing does have very high quality. Maybe because of my old PTFE tubing already has a small inner diameter, the optimal pressure advance value for me only lowered to 0.5 from 0.6.

-

I've got both the XS and TL series. The supposedly smaller inner diameter of the XS series is actually slightly larger than the TL series, but I'm sure it's just a batch issue. Both the XS and TL tubing does have very high quality. Maybe because of my old PTFE tubing already has a small inner diameter, the optimal pressure advance value for me only lowered to 0.5 from 0.6.

What sort of hot end do you have, and how long is the Bowden tube? It's unusual to need as much pressure advance as 0.5 or 0.6 except when using mixing extruders.

-

I've got both the XS and TL series. The supposedly smaller inner diameter of the XS series is actually slightly larger than the TL series, but I'm sure it's just a batch issue. Both the XS and TL tubing does have very high quality. Maybe because of my old PTFE tubing already has a small inner diameter, the optimal pressure advance value for me only lowered to 0.5 from 0.6.

What sort of hot end do you have, and how long is the Bowden tube? It's unusual to need as much pressure advance as 0.5 or 0.6 except when using mixing extruders.

I'm using it on a BCN3D sigma converted to duet wifi and 1.75mm e3d v6. The bowden tube is about 60cm. Maybe my way of finding out pressure advance value is wrong. I was doing a 20mm x 20mm tower in vase mode at 100mm/s speed. The problem on the corners resolves at a pressure advance value of 0.5.

-

Thanks! That's a perfectly good way of finding a good pressure advance setting (but see the caveat below). The corners look quite bad with no pressure advance, but perhaps that's because you were printing quite fast, and pressure advance matters more at high printing speeds.

One thing to watch out for is that high pressure advance settings have the side effect of reducing acceleration unless the extruder jerk is set quite high, and the reduced acceleration may contribute towards the pressure advance "working".

-

Thanks! That's a perfectly good way of finding a good pressure advance setting (but see the caveat below). The corners look quite bad with no pressure advance, but perhaps that's because you were printing quite fast, and pressure advance matters more at high printing speeds.

One thing to watch out for is that high pressure advance settings have the side effect of reducing acceleration unless the extruder jerk is set quite high, and the reduced acceleration may contribute towards the pressure advance "working".

Since pressure advance should work independent of speed, I purposely used a high speed for magnifying it's effect. I don't print at such high speed. My extruder acceleration is 5000mm/s and jerk is 10mm/s, whereas the X/Y acceleration is 2000mm/s and jerk is 8mm/s. I guess you are right, maybe the limited printing speed from pressure advance is contribute towards the pressure advance "working". I should re-run the test with lower X/Y jerk and higher E jerk.

-

Has anybody found a UK supplier of Capricorn PTFE Tubing XS- Low Friction?

-

E3D will be selling it soon.

-

I bought a chunk of this when ordering my Smart Effector. I didn't measure before hand or even after cutting it to attach to my printer, but I have 150mm left of whatever the length was that I got. I am currently running some pieces at 5mm retraction (no pressure advance) and haven't seen a whiff of stringing.

Direct drive extruder flipped so the marks being left by the extruder gear are on the inside radius of the Bowden tube.

Lower retraction tests soon to come.

-

E3D will be selling it soon.

Yes. I also noticed that they are including it with their "Gold Edition V6" https://e3d-online.com/v6-gold-hotend.

-

Yeah E3D have it listed now in 100mm lengths. Can buy longer lengths if you increase the qty