Issues with PrusaSlicer

-

I would guess there is an errant setting in the Prusa Slicer profile.

What does the gcode preview in that area look like?

Have you tried a built in print profile?

-

@phaedrux Thanks for the reply.

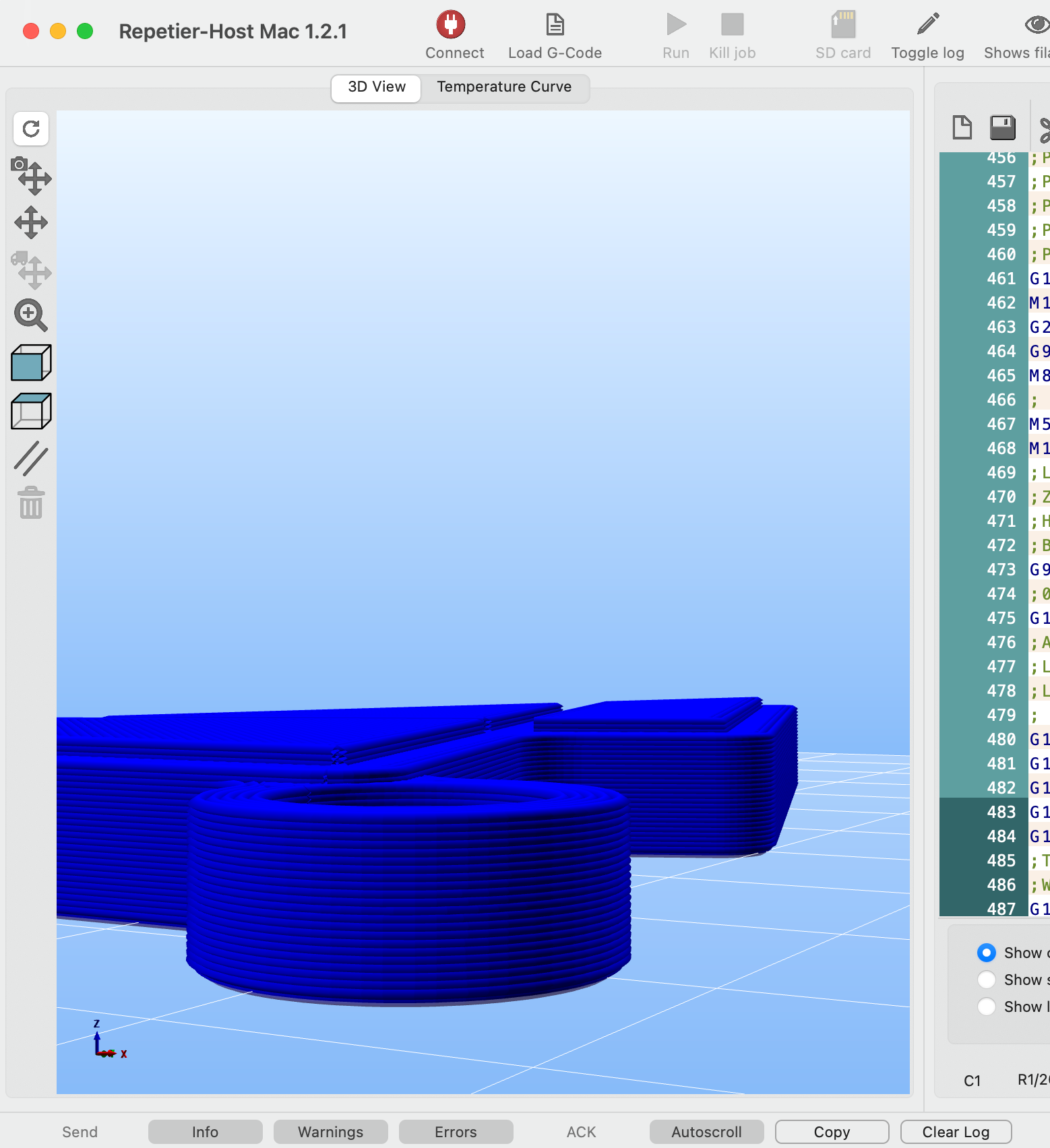

The gcode preview looks fine.

The profile has been built from scratch using the configuration assistant, custom printer with RepRapFirmware.

No big tweaks on the profile, except the gcodes scripts and multi extrusion parameters.I wasn't using PrusaSlicer before the Palette....

I am using Cura on a day to day basis, and S3D as a backup (it was my favorite for a long time, but it's outdated now against Cura 4 or 5)

Also printing the object with Canvas (Mosaic's slicer) with Slic3r provides the same bad results. Using Canvas with Kissslicer provides a good result on that feature but other issues regarding multi objects boundaries.

That's why I'm focusing now on PrusaSlicer + P2PP, which is on top more easy to control when set up. -

@Phaedrux Here's the PS project used (and also the S3D references)

https://www.dropbox.com/scl/fo/37dvmh94rsolk6lkr9m4l/h?dl=0&rlkey=zxedt939wq7q1kn0yb6d049m9

-

In Prusa Slicer print settings>advanced check the elephant foot compensation. That number causes the first couple layers to print smaller than the STL defined perimeter of the part to compensate for "elephant foot" which is a swelling of those layers.

My opinion is that elephant foot is an indication of too hot bed temperature, but they like to compensate for it by modifying the shape of the print instead of simply printing with a slightly lower bed temperature.

-

@mrehorstdmd Thanks for your reply.

I do have an elephant foot compensation of half the nozzle size, as usual and on both PS and S3D.

My issue is not at the bottom of the print, but in the infill layers which are just below the top solid layers.

That said, I'm not fully in line with your assumption, having many years 3D printing as a business.

Elephant foot is created mainly by the fact the first layers are too squished on the build plate, linked with incorrect bed leveling / flatness most of the time. Mesh bed leveling + proper tuning of the printer account for that.

Indeed bed temperature has an effect when set too close or higher than the glass transition temperature of the material.

Having a slightly smaller first layer accounts for the higher flow rate used on the first layer. -

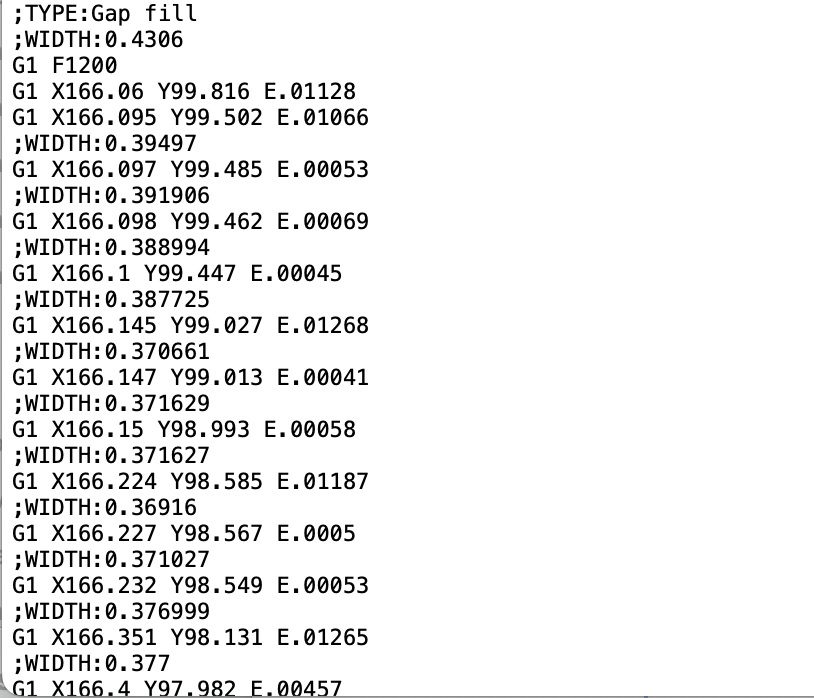

@Phaedrux I've been through the gcode generated by S3D and PS.

The main difference is that PS is making a variable line width gap fill on the top solid infill layers of the base part. (I have the feature "gap fill" enabled in PS).

I'm going to do a test print with no gap fill in PS

-

@v3dprinting I was not aware of elephant foot compensation on S3D. Are you manually creating that by using multiple processes?

Also, PrusaSlicer defaults like to have weird extrusion widths and layer heights for the first layer. Triple check that there is not some funny setting somewhere you didn't expect. Use explicit widths instead of percentages, and don't leave any extrusion widths blank otherwise Prusa will automatically choose a weird number for you. Make sure your nozzle is set to the right size too. In some of those auto-selected width cases, prusa uses the nozzle width to determine things.

-

@Phaedrux Bad luck, even with the "gap fill" feature disabled, I still have the same issue on my prints.

-

@bot said in Issues with PrusaSlicer:

@v3dprinting I was not aware of elephant foot compensation on S3D. Are you manually creating that by using multiple processes?

Yes, correct. I have a first process with the first layer only and an horizontal size compensation of half the nozzle diameter.

-

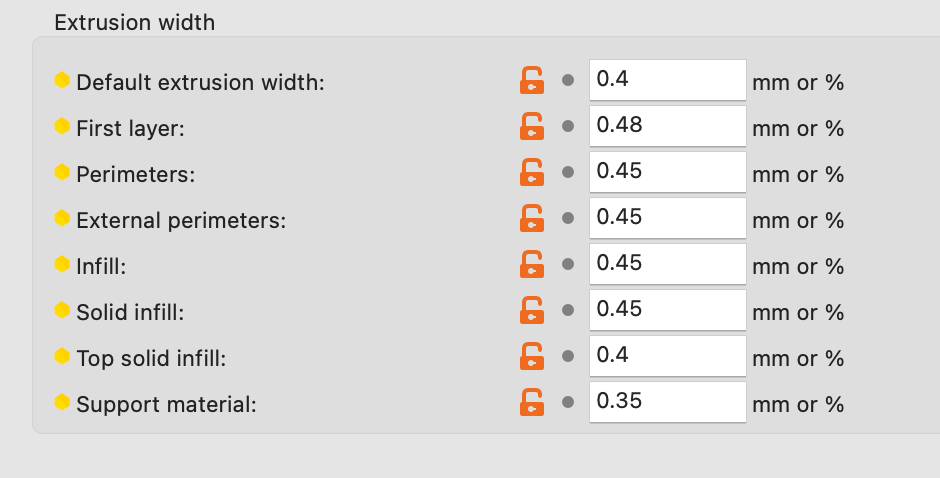

@bot I have checked extrusion width and layer height settings.

I had explicitly set widths at the beginning of my PS configuration. I remember the PS defaults were too weird regarding the references used...

I remember having played with the extrusion width and had them set all to 0.4 mm (nozzle size) for a test, to see if there's an impact. But no luck on that side.

-

@v3dprinting what is your nozzle diameter set to under printer settings?

IIRC, PrusaSlicer has different behaviour if the

extrusion width <= nozzle diameterPerhaps, increase the default extrusion width to .42 or .45. Otherwise, PrusaSlicer might be choosing different weird values for you (I forget the exact behaviour, but PrusaSlicer likes to do lots of things).

-

@bot The nozzle diameter has been set to 0.4 mm for all my 8 extruders (using a Mosaic Palette 3 Pro)

So except for the support material, I'm in the standard settings.I will make another try tomorrow, setting the default extrusion width a bit above the nozzle diameter as suggested.

Maybe having the default extrusion width = nozzle diameter is causing the issue. -

@v3dprinting given you are seeing the part taper in towards the top, could be that it is warping, rather than a specific part issue? It also sticks out at the top where you have the solid layers (and so are putting in a lot of heat and different cooling?).

Have you check what the temperatures and cooling fan percentages are between the two slicers? I know PrusaSlicer can display the cooling fan % thought the gcode preview

-

warping/shrinkage seems likely.

When does your layer fan kick in?

Can you try a print without the fan?

-

@engikeneer I 100% sure of my bed adhesion.

Many years of practice as a 3d printing service provider. -

@phaedrux

The part is printed in PLA, so shrinkage is minimal.

Remember the same part with same material on the same printer printed with S3D with the same main parameters turns out well -

@engikeneer said in Issues with PrusaSlicer:

Have you check what the temperatures and cooling fan percentages are between the two slicers? I know PrusaSlicer can display the cooling fan % thought the gcode preview

Temperature is even throughout the whole print.

I need to dig much more into the cooling settings as PS is fiddling with it. That’s a difference with S3D. Maybe the cause.Setting the default extrusion width to 0.42 for a 0.4 nozzle didn’t solved the issue.

-

@engikeneer

It looks like the layers were the issue happens are infill layers were the fan is on. For bottom and top solid layers, nearly no fan.

With S3D I have a constant 50% fan on starting layer 2 an 15% on first layer.

PS is making is own fan speed profile from 15 % to 50 % with my current parameters.

I need to get back to something much simpler and close to S3D first to see if it has an impact.

I will do the test tomorrow morning, when back in the office.

-

@v3dprinting said in Issues with PrusaSlicer:

@phaedrux

The part is printed in PLA, so shrinkage is minimal.

Remember the same part with same material on the same printer printed with S3D with the same main parameters turns out wellUh huh.

-

@phaedrux Yes, not as simple as a simple shrinkage.

I was a bit quick when setting up the cooling options, it's not as straight forward as on S3D or Cura.

I will do a new test print with PS with no variable fan cooling : 50% starting on layer 2 and always on.

I'll keep you updated