Bed leveling using strain gauges as endstops/probes

-

I am trying to figure out best way level print bed on my printer (Duet 3 6hc board). I was wondering if it was possible to use strain gauges at each contact point of the bed to sense touching of a nozzle. Measuring the actual force would not be necessary. Instead use of the strain gauges as simple adjustable LOW/HIGH switch would be enough. I would still use regular mehcanical endstops at max to roughly level the bed.

Adafruit Industries LLC 4543:

https://www.digikey.fi/en/products/detail/adafruit-industries-llc/4543/13148777Some benefits of this kind of setup:

- Automatic bed leveling is possible

- Doesn't matter what kind of hotend is used or what height it is.

- Hitting the bed can always be sensed

Some problems:

- How to connect/wire strain gauges (cant be directly connected to Duet)?

- Strain gauges use low voltages

- Price and finding suitable strain gauge

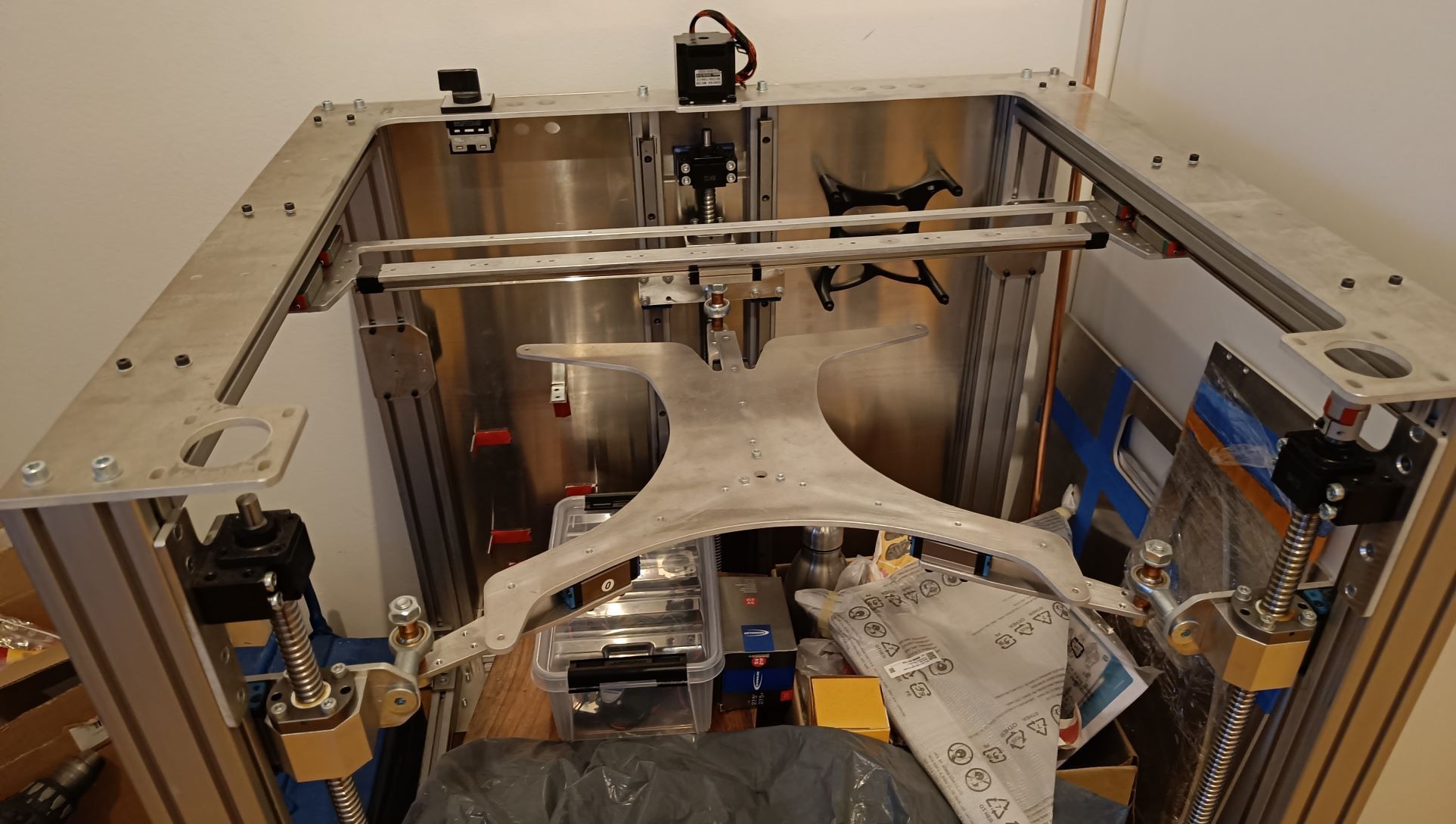

My printer has (or will have at some point) two extruders and 3 leadscrew bed setup that allows true bed leveling. The bed itself is machined aluminum plate with glass sheet as print surface so it can be assumed to be flat. I was thinking of placing the strain gauges at each arm plate (between ball joint and linear rail blocks in the picture).

-

@visionary strain gauges need to be used with amplifiers. There are some standard strain gauge ICs available, however many of them have slow sample rates because they are intended for use in digital scales.

To detect nozzle contact with the bed, you don't need to read absolute values of load, just sudden changes. You could use a circuit similar to the one we use in the Smart Effector version 3, which you can find at https://github.com/Duet3D/SmartEffector/tree/master/SmartEffector/SmartEffector_v3.0. With a little modification you could feed the output from the three op amps to a single attiny microcontroller.

An alternative would be to use force sensitive resistors, which have been used for many years on delta printers. See https://reprap.org/wiki/FSR for an overview. You can buy a board that interfaces three FSRs to a controller, see https://github.com/JohnSL/FSR_Endstop.

-

an alternative strain gauge design that uses resistors like Smart Effector is available at https://github.com/IvDm/Z-probe-on-smd-resistors-2512 and may be easier to adapt for a typical box style printer.

-

Using actual strain gauges seems hard. FSR mounting is not easy either, but it is much easier to wire/connect to Duet if I can just make use of voltage dividers.

-

@oliof said in Bed leveling using strain gauges as endstops/probes:

an alternative strain gauge design that uses resistors like Smart Effector is available at https://github.com/IvDm/Z-probe-on-smd-resistors-2512 and may be easier to adapt for a typical box style printer.

I advise against using the electronics in that design because the HX711 chip it uses suffers from the slow sample rate that I mentioned.

-

@Visionary on a complete side note, I really like you implementation of your bed setup. I have been looking for a way to do that without printing parts. Given me some food for thought

-

I used the FSR and johnsl board on my delta for awhile and it did pretty well after working out some kinks in my mounting. Mapping a bed for delta autocal isn't so great since there is some deviation in response simply since the force varies between 3 sensors based on where you touch, but for leveling it was more than sufficient. Main reason i went contact-less on any sensor i could. Using a brass nozzle to touch the bed would deform the hole eventually, enough to irk me on a calibration cube (well, immediately if i crashed as you'd expect). The johnsl board would likely do great on sensitivity if the fsr's weren't loaded by a weight like the bed depending how you arrange it too.

-

@samlogan87

If I did another printer like this I would use belts instead of screws on z-axis. However, Use of screws allowed me to not have any printed parts on z. -

@lord-binky

I just ordered some fsr resistors. I was thinking of adding potentiometers in series with them or correcting z height with g-code commands if necessary. If adding fsr resistors to bed wont work I will try putting them on extruder instead. -

@visionary if you are using FSRs then I suggest you get the JohnSL board.

-

I couldn't find European supplier for them, but I will try ordering one from the US.