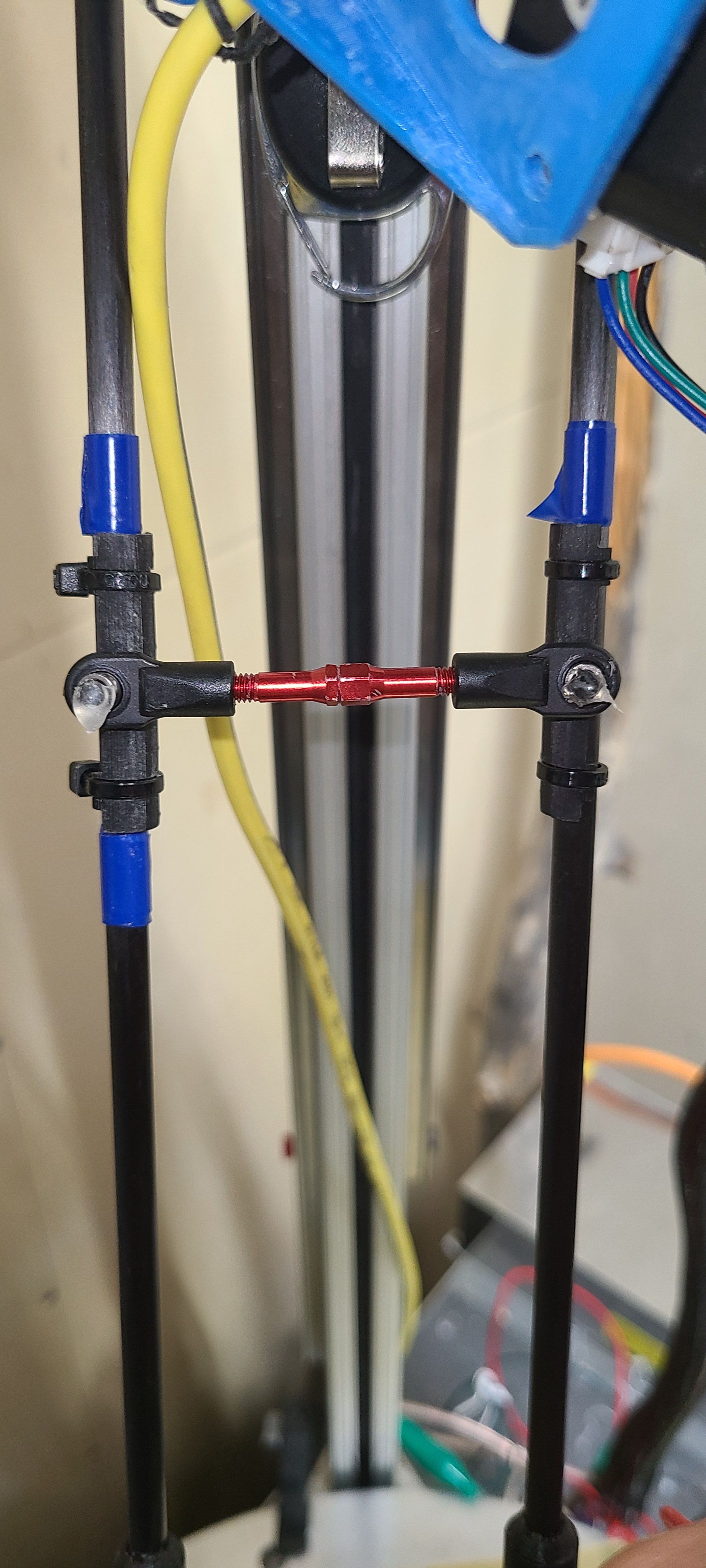

So I was about to keep chasing down rigidity in the arms of my delta printer and started poking around to see what else could have play in it. Linear rails, ball ends, arms are all really rigid, you tap on the carriage with your finger nail you feel it in each of the carriages like it was solid. Nothing stood out as a "wiggly". But then I realize I can move the effector, it returns to the same point, everything's connected well but there's play? I test it by using probing distance for reference. Turns out I can wiggle the effector over .5mm and even then unless I feel motors skip a step, the impact on the z probe is from 0.247 to 0.266. So outside of skipping a full step, it might (and usually did not when I was toying with it) mess up a microstep. So it's a spring like motion up to at least .5mm that returns effectively to the exact same spot. I feel around again, pushing on the effector even a slight bit you feel a corresponding movement in the belt up by the idlers. And this has me stumped, because nothing improves tightening a belt so it's not loose belts.

I feel like if I can address whatever "play" in the effector this is it would seriously help out on ringing. My gut says it is not in the belts, but it wouldn't be far fetched to say 9mm belts vs 6mm belts just don't do that. I feel like it is the stepper motors that are behind that movement, but I'm using 0.9 2.4A Nema17's ( Wantai 42BYGHM810) @ 2.4A. The play is not originating from the stepper motor shaft flexing (I have bearings stopping that).

I really like the performance I get from them otherwise so I'm stumped if I'll actually eliminate this flexible movement changing to a NEMA 23/24 and just taking the hit on motor specs (these ones have like 1.8mH inductance, nice for speeds on 24V). Would I have to go to closed loop steppers that'll actively counter that flex, but I'm not sure it'd even register since everything returns to normal after pressure is removed. And to rub it in, I feel like even if it's in the belts or steppers, how is this not prominent in those speedy CoreXY builds, they have long lengths of belts like my delta and nema17's (I think) are common components for them. Or is that just overlooked because it disappears when you go full servo.

My only options left in the sytem for the source of it is pulleys, belt, and stepper. I suppose pulleys could be the other issue, I don't have much for options on one half but I could swap idler pulleys to a large diameter and use a deflector pully to keep everything lined up. I'd love some input.