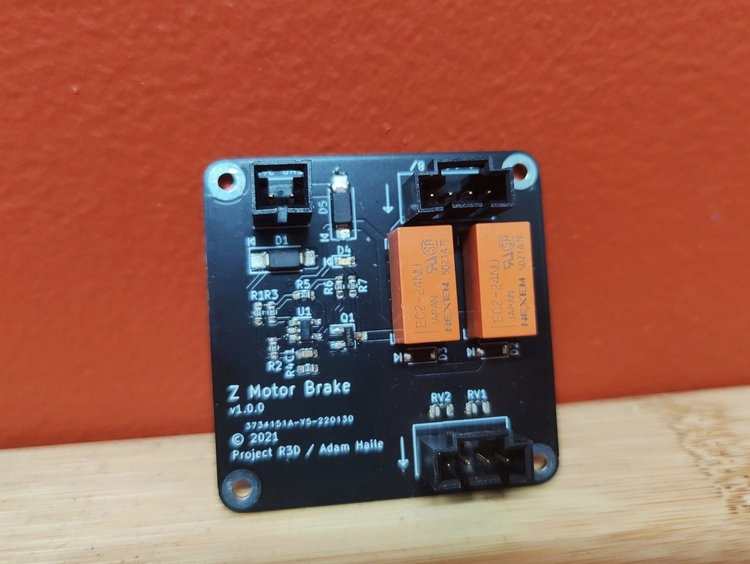

New product: Electronic Z motor brake

-

Not Duet specific but discussed here a few times. This new product is connected in serial to Z stepper motors (e.g. non-geared belted) and is supposed to brake the motor by shorting its coils when the controller stops providing power.

https://www.projectr3d.com/shop/p/z-motor-break

-

@zapta We got to check these out at MRRF. We initially went down this path and had working prototypes but opted to switch to z-steppers with electromagnetic brakes as our heavy gantries could/would still drop when powered down. However, for a lot of machines out there, this will be a great solution!

-

@oozebot, a card like this could also have a dry contact output to automatically activate a mechanical brake.

-

Do you have any video comparing bed drop without and with this device?

-

cool product

cool product -

@3dpmicro, another related cool product is a counter balancing spring https://youtu.be/EVZu_KIni_o?t=657

@mrehorstdmd , I don't have an experience with this product but you can try shorting the coils of a stepper and see how much resistance you get, including long term slow slippage, if any.

-

When the coils are shorted, the braking force is proportional to the motor speed. At zero speed there is no electromagnetic braking force, only the detent torque of the motor plus friction. So when a single Z motor is used to control a belt-driven Z axis, the effect of shorting the coils after power is removed will typically be to reduce the speed at which the bed drops. This may be acceptable if the drop is slow enough and the bed has a soft landing when it reaches the bottom. If the Z axis uses multiple motors then unfortunately they may drop at different rates, which would lead to the bed becoming skewed.

RepRapFirmware 3.4 supports motors with brake solenoids, which can be purchased from stepperonline and elsewhere.

-

@dc42 , Nero 3D tested the electronic brake with a core XZ printer and it works very well for him. There is only one caveat, it drops down over 10-15 minutes.

https://youtu.be/-39GtYVHS6M?t=866

Reminds me this experiment https://youtu.be/bP200zhX63Q?t=50

-

@zapta

I just read this for the 1st time and thought: maybe braking the belt would be an alternative?

Think of a hobby servo with excenter, which clamps the flat side of the belt against a solid surface, just before you switch off the printer... -

@o_lampe , that's an interesting idea.

Another approach is not to brake the motor or belt but to park the carriage. E.g. it moved to a given height and one or more servo/solenoid activated pins lock it in place.

BTW, the Voron Switchwire uses this to balance gravity. https://www.amazon.com/KEY-BAK-SUPER48-Retractable-Polycarbonate-Oversized/dp/B0088MQA10

Edit: from dc42's post above: "RepRapFirmware 3.4 supports motors with brake solenoids, which can be purchased from stepperonline and elsewhere."

-

If you're using a belt to lift the Z axis, you can most easily prevent Z axis drop by using a worm gear reducer on the motor. It doesn't require any extra electrical connections or any special configuration, and it stops the Z axis from moving at all when power is cut. I have one of these 30:1 reducers in my printer's Z axis (yes, one motor, so no autoleveling needed or used). It is driven by the driver chip on the Duet2 controller (current set to 1A). At that current it easily lifts a 3.5kg bed plus 4 kg of print weight. I set steps/mm in config.g and it's done. I chose drive pulleys that yield 20um/full step, so I get excellent Z axis quality when printing in layer thickness that is a multiple of 20um (100 um, 200 um, 500 um, etc.).

Note- you can get cheap planetary drives on steppers, and if the reduction ratio is high enough they might prevent Z axis drop, but they don't have whole number reduction ratios (read the fine print!) so you won't get "nice" full-step values from them.