another spurious heater issue

-

So I am setting up a duet 2 wifi board

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.4.1 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2022-06-01 21:05:38It's a Tevo Tornando cartesian printeer with a bunch of upgrades being switched over to a Duet board.

(Version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Sat Jun 25 2022 21:34:00 GMT-0230 (Newfoundland Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"&^&%^$" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes forwards//backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards//backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E417.87 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y300 Z400 S0 ; set axis maxima; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S3 ; configure sensorless endstop for low end on Y

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y-12 Z-.153 ; set Z probe trigger value, offset and trigger height

M557 X25:245 Y25:280 S50 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 R4700; configure sensor 0 as thermistor on pin bedtemp /4138 added r4700

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M307 H0 R0.463 K0.164:0.000 D19.80 E1.35 S1.00 B0 ; bed autotune parameters

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 R4700 ; configure sensor 1 as thermistor on pin e0temp /4138 added r4700

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M307 H1 R3.087 K0.572:0.000 D3.68 E1.35 S1.00 B0 V24.1 ; hotend autotune parameters

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Display

M918 P1 E-4 F2000000 ;setup of 12864 full graphics display; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory/disabled to test thermistorI was getting bed heat errors which i (Seemed???) to manage by switching out for a new thermistor which I pid tuned. I tuned my hotend and I leveled my bed with a simple 50mm mesh with just my bed heating. I want to do a better 20mm mesh with my hotend heated to 120 as well. I get

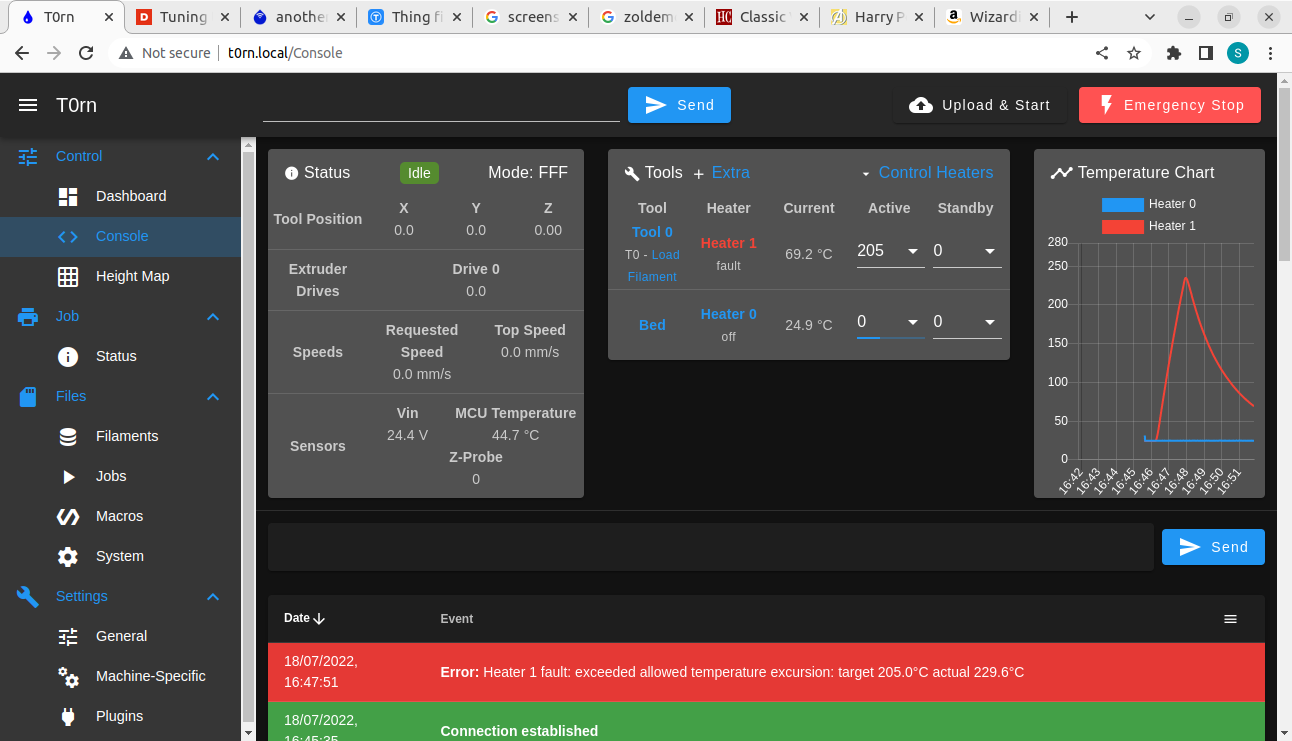

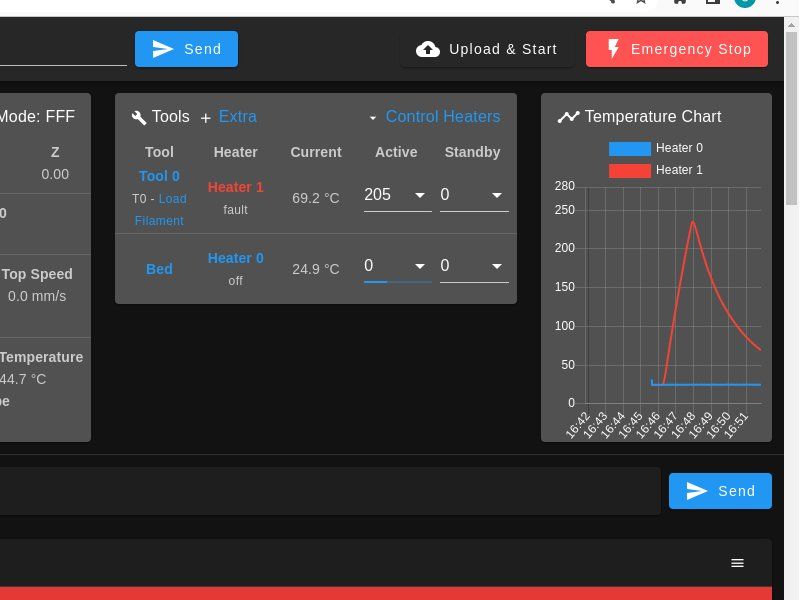

Error: Heater 1 fault: exceeded allowed temperature excursion: target 120.0°C actual 135.5°CI tried switching out thermistors and still ge the same error.

Thermistor type

100k Hisense 3950 - 1% up to 300°C for hotend "Simple ONE " & "All In ONE"

Im pulling my hair out atm. -

What does the temp graph looks like when it errors?

Is it heater1 or heater0 producing the error?

-

@cncmaker

Bang Bang Mode and PID Tuning for the Bed, could that be the Error ? -

@günter-jibben The error you posted referred to heater 1 which is the hot end, not the bed. Furthermore, the error stated that the target temperature was 120 but the actual was 135. So you either have the wrong thermistor values causing it to read high, or you have a big overshoot which might possibly be caused by using too large a heater cartridge for the heater block. You have several options. You could try PID tuning the heater to 120 but that would likely cause problems at "normal" print temperatures. Or you could increase the heater fault tolerance so that it doesn't error with a 15 Deg excursion. Or you could try your bed mesh with the hot end at normal print temperatures rather than the lower 120 Deg C. That's all assuming that you have the correct thermistor values for the sensor and you don't wish to use a smaller heater cartridge.

-

@deckingman said in another spurious heater issue:

@günter-jibben The error you posted referred to heater 1 which is the hot end, not the bed.

No, it's not like that.

I was referring to the following command lines...... M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M307 H0 R0.463 K0.164:0.000 D19.80 E1.35 S1.00 B0 ; bed autotune parameters ...I was referring to the bed, not the hotend.

Here Bang Bang is activated and also the PID tuning for the bed.

I always thought until now... both together does not work.Am I wrong, has it changed over the course of the firmware updates?

Do I need an update now ?

Google Translate

----- Original Text -----Nein, dem ist nicht so.

Ich bezog mich auf folgende Kommandozeilen...... M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M307 H0 R0.463 K0.164:0.000 D19.80 E1.35 S1.00 B0 ; bed autotune parameters ...Ich bezog mich auf das Bed, nicht auf das Hotend.

Hier ist Bang Bang aktiviert und auch das PID Tuning für das Bed.

Ich dachte bis jetzt immer... beides zusammen geht nicht.Liege ich da falsch, hat es sich im Laufe der Firmware-Updates verändert ?

Brauche ich jetzt ein Update ?

-

@günter-jibben You said this.................

.............with my hotend heated to 120 as well. I get

Error: Heater 1 fault: exceeded allowed temperature excursion: target 120.0°C actual 135.5°CHeater 1 is the hot end - not the bed. So the fault that was generated refers to the hot end reaching 135.5 deg C when the target temperature was set to 120 degC. You can play around all you want with the bed PID settings, but it won't have any effect on the hot end heater fault.

-

@deckingman

You are confusing something there. @cncmaker wrote that, not me.

He has the problem and I just wanted to help.

----- Original Text -----

Da verwechselst Du etwas. Das hat @cncmaker geschrieben, nicht ich.

Er hat das Problem und ich wollte nur helfen.

-

@günter-jibben Ahh OK. For info, the OPs second M307 will override the first. So the B1 in the first M307 will be overridden by the B0 in the second M307 (but he still has a problem with heater 1, which is nothing to do with the PID settings for heater 0).

-

@deckingman

Oh, that will be completely overwritten, I thought it would complement each other and this could lead to errors.

OK thank you for the info.

Yes, then the problem is probably somewhere else.

Google Translate

----- Original Text -----Ach das wird komplett überschrieben, ich dachte es würde sich ergänzen und dadurch könnte es zu Fehlern kommen.

OK, Danke für die Info.

Ja, dann liegt der Fehler wohl woanders.

-

Thank you for the help. Sorry about the confusion I am currently having issues with H1 the hotend heater. I was having the opposite issue with the bed that it wasnt heating up fast enough.

Ive built 14 cnc type machines and designed 7 of them. I have modded/upgraded/overhauled a couple hundred machines. CNC, 3d printers, engravers, plotters, whatever.

I usually use marlin or GRBL except for one rrf machine and that was running rrf1 and I didnt like it too much. This tevo overhaul is a customer request. I am still on the fence about rrf overall I like it I just need some more screw ups to happen so i actually know what I am doing. Im thinking about switching my MPCNC over to rrf if I can figure it out.

@Phaedrux

@deckingman I am not 100% sure if I have the thermistor set up properly.I know it is a 3950 100k thermistor. I use it as a type 13 with marlin all the time.

I have a bunch of thermistors but dont know the values of them and find it hard to figure out exactly how to determine the b number i need. I can easily measure resistance i have a high end fluke meter with temperature but not a second meter. I installed it then tuned it i thought correctly but it seems i have something messed with my config file.One thing about the thermistor say the value was incorrect so why the overshoot? Its not reading right when does the machine realize that 120 is 135? If the thermistor is wrong its wrong it should just goto 120 and think its 120 even if its only 80, instead of blowing by it. Am I wrong?

I seen in thnother thread about some heater issues faults with 3.4 i was thinking of downgrading to 3.3.

-

@cncmaker You haven't necessarily messed anything up. If you've done the PID tuning and correctly entered the results in your config.g, then it might just be that the heater is overpowered for the heater block. PID control can only do so much. I have very little information to go on except your original post where you stated that there was a fault message triggered by the heater reaching 135 when the set point was 120. Coupled with what seems to be a rapid rise time in the graph you posted, indicates that it might be a temperature overshoot. What is the power of the cartridge and are you sure it's the correct voltage for your machine?

You don't have an M570 in your config.g so default values would apply. You could use M570 to provide wider fault tolerance (say 25 Deg for 20 secs), but be aware that if you get a genuine fault, bad things might happen.

-

@deckingman said in another spurious heater issue:

@cncmaker You haven't necessarily messed anything up. If you've done the PID tuning and correctly entered the results in your config.g, then it might just be that the heater is overpowered for the heater block. PID control can only do so much. I have very little information to go on except your original post where you stated that there was a fault message triggered by the heater reaching 135 when the set point was 120. Coupled with what seems to be a rapid rise time in the graph you posted, indicates that it might be a temperature overshoot. What is the power of the cartridge and are you sure it's the correct voltage for your machine?

You don't have an M570 in your config.g so default values would apply. You could use M570 to provide wider fault tolerance (say 25 Deg for 20 secs), but be aware that if you get a genuine fault, bad things might happen.

So I'm just about to determine the thermistor by measuring the R at 25C and then 100c, change it over to Kelvin then some division I believe and confirm the thermistor for sure.

So its a micro Swiss hotend with a 40w cartridge. This is mostly a conversion on a working tevo tornado that I've already done a bunch of upgrades to.

Thank you for the m570 idea though I can at least make the machine work now

-

@cncmaker just double checking, you aren't using a 12V heater in a 24V system? else you'll actually have a 160W heater and bad things may happen...

-

@engikeneer said in another spurious heater issue:

@cncmaker just double checking, you aren't using a 12V heater in a 24V system? else you'll actually have a 160W heater and bad things may happen...

I wish thats what it was. I measured the resistance it came out to 14.8r so thats a 24v cartridge

-

Can you post your config-override.g file? Maybe you're loading some old tuning values that are over writing the values you've copied into config.g

Did the PID tuning for the hotend heater go alright?

That rapid of a heatup sure seems like a 12v heater on a 24v system. Do you have another cartridge to test with?

-

@phaedrux sorry for the late reply I had to go away for a little while.

config-override.g

The cartridge had 24v printed on it and the measured resistance of the cartridge was 14.7. On top of that the cartridge works with marlin. I will still try another cartridge as I have many. -

Config-override.g

M307 H1 R3.052 K4.617:0.786 D4.61 E1.35 S1.00 B0 V24.1Config.g

M307 H1 R3.087 K0.572:0.000 D3.68 E1.35 S1.00 B0 V24.1Is that perhaps the difference between you tuning it as a tool, versus tuning it as a simple heater?

-

@phaedrux

So I went into the override file and it says dont modify or delete lines or whatever. So I took the tuning values from the config file and pasted them in. This worked.I always wondered why it showed as a tool so what did i do wrong and what can i do to fix it?

Thanks alot

-

the values in config-override.g are written there when you send M500. Which you would normally do after tuning completes.

What command did you use to start the tuning?

-

@phaedrux m303 h1 s240 or something like that. I cant seem to see a history of my commands in dwc.

I dont know if i should start a new thread but id like to ask you about another issue im having.

I followed this link to connect a 12864 display I used this menu system suggested in the above link.

I tried updating thru dwc all it did was put the folder on the system. I seen that the files are suppose to be in a menu folder which i created and added the files to it. Im using a reprap full graphics display which is a 12864. I dont get any sort of menu on the display.