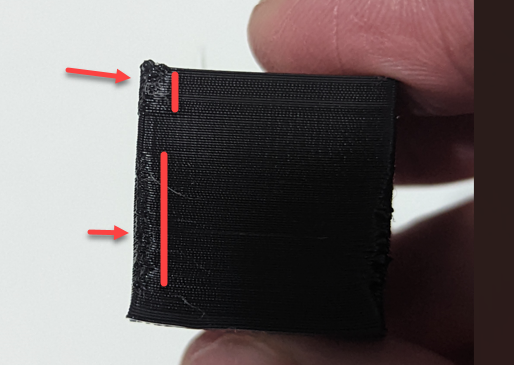

Help me identify what would be the cause of these artefacts

-

Hi all.. I'm doing some printer calibration and noticed on my XYZ cube, I get these odd artefacts on the edges, at inconsistent areas.

It looks like it's too hot and melting, or possibly over-extrusion? But I've just calibrated my e-steps and tested the feed 3x times and it's spot on now, but then I get this so I'm unsure.

Can someone suggest some possible causes of this so I can investigate?

Thanks!

-

@timsworkshop usually insufficient cooling and/or dwelling time due to low jerk and acceleration times.

-

@timsworkshop

If the nozzle stalled in those places, the cause could be an SD card that is too slow.

Here are the instructions for testing the speed of your SD card (Duet3D Docs).Another cause could also be an uneven diameter of the filament.

When measuring the diameter, note that many filaments are not circular but somewhat oval, so you should turn the filament at the point where it is measured and measure it again.Have you set a retract in the slicer at the beginning of the next shift?

What is the retract (Bowden or Direct).

I'm thinking of the filament clumping together for a short time during the heatbreak.

Or problems with the Z-seam.There are bound to be some sources of error from other commentators.

Google Translate

--- Original Text ---Wenn die Düse an den Stellen stockte, könnte die Ursache eine zu langsame SD Karte sein.

Hier die Anleitung zum testen der Geschwindigkeit Deiner SD Karte (Duet3D Docs).Eine andere Ursache könnte auch ein ungleichmäßiger Durchmesser des Filaments sein.

Beachte beim messen des Durchmessers das viele Filamente nicht Kreisrund sind sondern etwas Oval, daher sollte man das Filament an der Stelle wo gemessen wird, das Filament zu drehen und erneut messen.Hast Du im Slicer ein Retrakt zu beginn einer nächsten Schicht eingestellt ?

Wie hoch ist der Retrakt (Bowden oder Direkt).

Ich denke dabei an kurzzeitiges verklumpen des Filaments im Heatbreak.

Oder Probleme mit der Z-Naht.Es kommen bestimmt noch einige Fehlerquellen anderer Kommentatoren hinzu.

-

what slicer did you use... try another i had issues with cura and flow infills and over all flow rates which made the z seam or start stop bad like this

super slicer reprint for me was all it was

as for cura infill flow i used was 89% and the total flow rate to 98% fixed this on ASA prints and othersusually if the Z seems are bulging flow or retractions are out but speeds do play apart here too!

-

it also looks like you dont have any/much cooling on it or elephants foot compensation but try another slicer if you have active cooling working

what is the material? -

Thanks everyone for the suggestions! I've done some tweaking on the pressure advance, flow, steps etc. and it does look a lot better. I still get some bulging on these bottom edges, but on other test prints I get near perfect prints.

For the slicer question, I use PrusaSlicer and it seems to do pretty well.

-

@rexx Yeah, I started using rafts more to reduce the elephants foot and it has helped a lot. I use PrusaSlicer and do have elephants compensation at .2 for my .04 nozzle, but still see this problem.

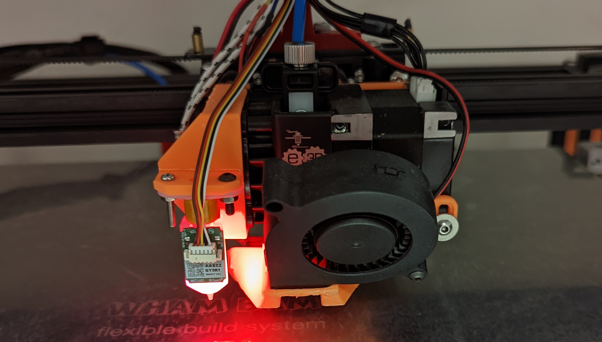

It may very well be cooling and I am looking for alternative part cooling shrouds for my Hemera.

-

rafts are great when needed did you look around to see if you can mate a generic one up for the Hemera? show us a pic maybe we can help

try it with some fan on initially... -

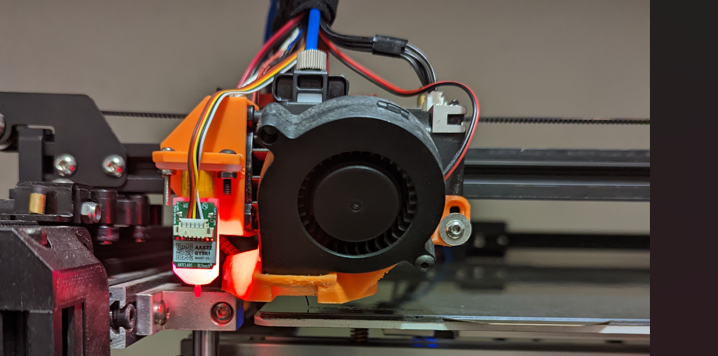

@rexx Thanks mate. This is my fan shroud and I think my hemera setup is sagging on the left as no matter what I do, I cannot get this left hand side more green than blue.

I previously had a Microswiss and could get pretty level meshes, but with this Hemera, my left side is always sagging down.

The other weird thing is when I put a level on my bed, it is not showing level at all, and if I try to adjust according to the level, then fun a

G32, I have to make huge adjustments, which puts me back on a unlevel bed (according to to the level, but notG32) -

@timsworkshop

While I don’t think this is your main problem, food for thought.

Is that Capricorn tubing you are using for your filament feedpath? I’ve had issues with Capricorn tubing in the past dragging on the filament resulting in inconsistent feeding of filament. I would suggest moving to standard ptfe tubing or even thin walled tubing as it appears you are using a direct drive and the tighter ID of Capricorn can cause more drag.Just a thought!

-

@timsworkshop said in Help me identify what would be the cause of these artefacts:

The other weird thing is when I put a level on my bed, it is not showing level at all, and if I try to adjust according to the level, then fun a G32, I have to make huge adjustments, which puts me back on a unlevel bed (according to to the level, but not G32)

Please post the contents of the config.g and bed.g files.

In order to understand it correctly, since I don't speak English very well, I use the Google Translator and it translates some texts so cryptically that you have to guess what is meant, and sometimes there are problems with understanding.

That's why I usually post my comments in two languages, so that in case of problems with understanding, a user who speaks both languages can clarify the situation.

It has happened before.

So you use G32 to get a mesh for the later automatic bed leveling (ABL) after manually leveling the adjustment screws and heating up the print bed ?

And then you have the suspicion that this ABL is not used at all, because the prints don't hold up or, as in the case of the cube, some layers look squashed ?Please also post which filament you use exactly (brand and name) and also post the temperatures with which you printed this filament.

Google Translate

--- Original Text ---Poste doch bitte mal den Inhalt der config.g und der bed.g Datei.

Um es richtig zu verstehen, da ich die englische Sprache nicht sooo gut beherrsche, nutze ich den Google Translator und der übersetzt manche Texte so kryptisch das man raten muss was gemeint ist, und es dabei manchmal zu Verständnisproblemen kommt.

Deswegen poste ich meine Kommentare auch meist in zwei Sprachen, damit im Fall von Verständnisproblemen irgend ein User der beide Sprachen beherrscht, die Situation klären kann.

Es ist schon einmal vorgekommen.

Also Du nutzt G32 um nach dem manuellen Leveln der Einstellschrauben und dem aufheizen des Druckbettes diesen G32 Befehl um ein Mesh zu erhalten für das spätere automatische Bettlevelling (ABL) ?

Und dann hast Du den Verdacht das dieses ABL gar nicht angewandt wird , da die Drucke nicht halten oder wie im Fall des Würfels, manche Layer gequetscht aussehen ?Poste bitte auch welches Filament Du genau benutzt (Marke und Bezeichnung) und poste auch die Temperaturen mit dem Du dieses Filament gedruckt hast.