Independent Dual Gantry - any examples out there?

-

I got a different message in this thread about the possibility of making a dual gantry work; what missing feature would be needed in RRF 3.5 to enable this?

Thanks.

Also, are you aware of any public references to a machine like this? I'll put mine on GitHub soon enough, but curious to see any others. Dual Gantry is a lotta work, but it's definitely an interesting setup if your goal is to learn.

-

@zruncho Yes, if you define multiple tools in the slicer, and load a model that needs more than one type of extrusion, the slicer takes care of sending the commands to change tool. When a tool change command is received, the Duet takes over the actual tool change, using whatever has been programmed into the tool change macros. See https://docs.duet3d.com/en/User_manual/Tuning/Tool_changing

The development in RRF 3.5 is for independent streams of Gcode, ie you can run two different gcode files at the same time, and cause the different tools to move independently. However, some coordination may be necessary if trying to print two different objects, each with a different tool; the firmware doesn't stop clashes between tools trying to move in the same area (probably best to limit print area of each tool so they can't clash), or synchronising layer changes (not sure how this is going to get dealt with). Fun times!

Ian

-

Interesting. I really don't see how that would be useful without a way to sync Z motion between the two streams. What's the driving use case for that functionality?

-

@zruncho for a simple single gcode stream idexy it's def possible. I've been working on two designs for a while now but other projects have pushed them back in priority. Remember you are still gonna need a way to adjust z on one head to the other with the probe.

-

@zruncho would love to see the printer and what belt routings you went with.

-

On my Hybrid-CoreXY IDEX ("Double Dragon"), I enlarged the toolhead mount holes slightly, then tapped one toolhead into position, using a shared nozzle endstop to precisely measure the Z height difference. Took < 5 m to get < 0.01mm alignment.

https://github.com/zruncho3d/double-dragon

https://www.youtube.com/watch?v=GY29F2O1unw

Gonna do the same thing on the IDG printer, since I know it works...

-

I'll share it all on GitHub once I've addressed a few minor items, just like all my other printer mods:

As a teaser, imagine two BoxZero gantries, with one rotated 180 degrees, plus all-custom XY joints so that both gantries can have shared rails.

-

On v3.4, I was able to get everything working without issue, from your suggestions. Thanks!

It was all pretty straightforward - define a CoreXYUV, map the axes and endstops, and verify it all as a CoreXYUV, first. Then set up to the tools, where the second one maps (U, V) to (X, Y), and ensure they work as expected with T0 and T1, where each of these parks the toolhead.

Seems all good... with no pain, surprisingly, so far. I know the XY offset calibration to come will be the bigger pain.

-

@zruncho super interesting! for someonwhat simplified belt runs, you could look at Dual Wire Gantry / Slid3r kinematics.

-

@zruncho said in Independent Dual Gantry - any examples out there?:

On my Hybrid-CoreXY IDEX ("Double Dragon"), I enlarged the toolhead mount holes slightly, then tapped one toolhead into position, using a shared nozzle endstop to precisely measure the Z height difference. Took < 5 m to get < 0.01mm alignment.

https://github.com/zruncho3d/double-dragon

https://www.youtube.com/watch?v=GY29F2O1unw

Gonna do the same thing on the IDG printer, since I know it works...

The main culprit about dual independent gcodes is: you can't use mesh leveling.

So, even when you have adjusted both toolheads to same height, your bed needs to be 100% flat and true to the XYUV axes.I've designed a 4-toolhead printer called the hashPrinter. It's not a CoreXY design, which makes beltpaths short enough to increase the framesize. I can park all tools outside of the printzone, which eliminates the need of most of the endzone dance you described on your Github.

See here for details -

Amazing work on that! I hadn't really understood it from skimming the thread, but I watched your video:

https://www.youtube.com/watch?v=Lo-ymCO0Ekw... and the great animations made it clear. How did you do them?!?!?

Anyway, I'm personally not too worried about mesh leveling, as all my printers either use a MIC6 bed or glass plate and none require mesh leveling, just bed tramming. A little variance in the first layer is probably OK anyway, especially if using textured beds, with parts that have first-layer chamfers.

re: parking outside - that's an option w/a Dual Gantry too. You can do that with the world's simplest T0/T1 gcodes to move to a parking position:

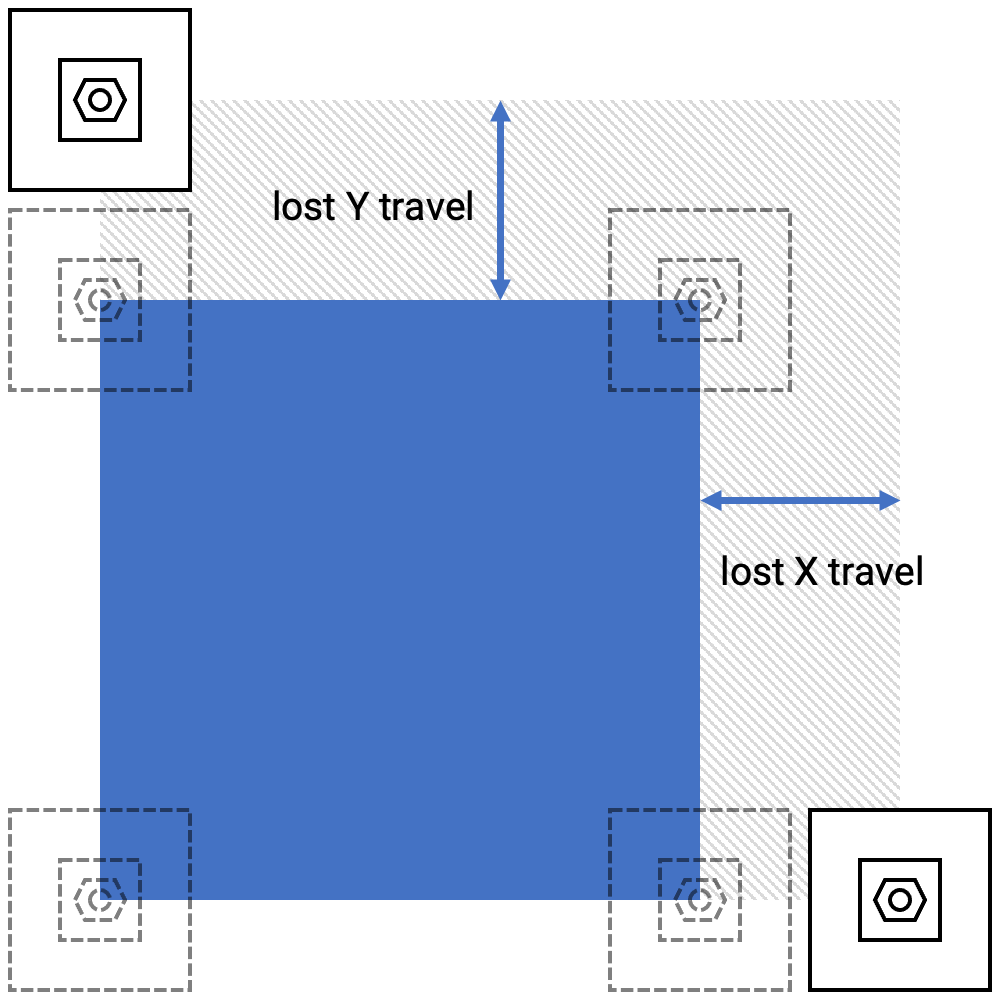

https://github.com/zruncho3d/DuelingZero/blob/main/Diagrams/workspace_dual_corners.png

-

modern magnetic flex Steel print surfaces are easy to shim too. you can even have differently shimmed sets for different target temperatures.

-

@zruncho said in Independent Dual Gantry - any examples out there?:

... and the great animations made it clear. How did you do them?!?!?

They're not my work, but a starting point for my design with the anti-racking Aramid wire stuff. I can drive each axis with only one belt, which makes the whole setup very compact and simple.

@oliof I agree, we don't necessarily need mesh leveling, since there is also the option to print a raft first.

But I mainly build prototypes with a little less accuracy, just as a proof of concept. So I'm glad there is some cheat mode available....and there is still no cure against gantry sag, other than mesh leveling. Except building an oversized, but heavy gantry.

-

Appreciate that this is an old post - but I have been recently doing some investigations of dual gantry IDEX printers, and came across this post via the zrucho3d DuelingZero design on github.

I am looking at creating something probably based on a Ratrig VCore4 RMMU IDEX, but with a 2nd IDEX Gantry added.

Looks like with that number of motors and also ideally getting the system to do parallel colour changes on idle extruders that I would need to be looking at Reprap 3.5 at least as the firmware.

Initial ideas in a series of video animations if anyone is interested.

It won't let me post the link as I am new to this forum - but should come up hopefully if you search for 'IDEX Part 3 dual' on youtube.

-

@dwuk I presume the link you were not allowed to post is https://www.youtube.com/watch?v=IhzRKjXgYK4. and the Github link is https://github.com/zruncho3d/DuelingZero.

-

@dc42 Thanks yes - thats the correct links.

I have just created a longer post with a few more thoughts on the Multi Axis Printing / IDEX Both on Core XY thread.