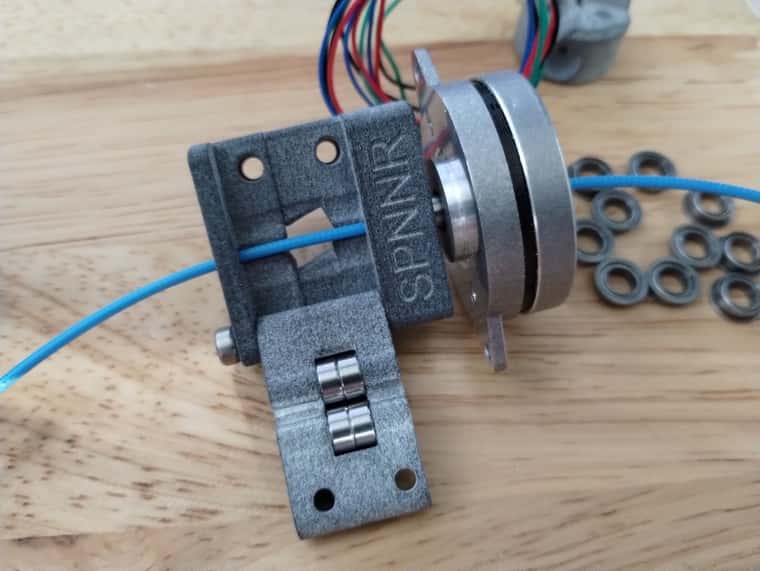

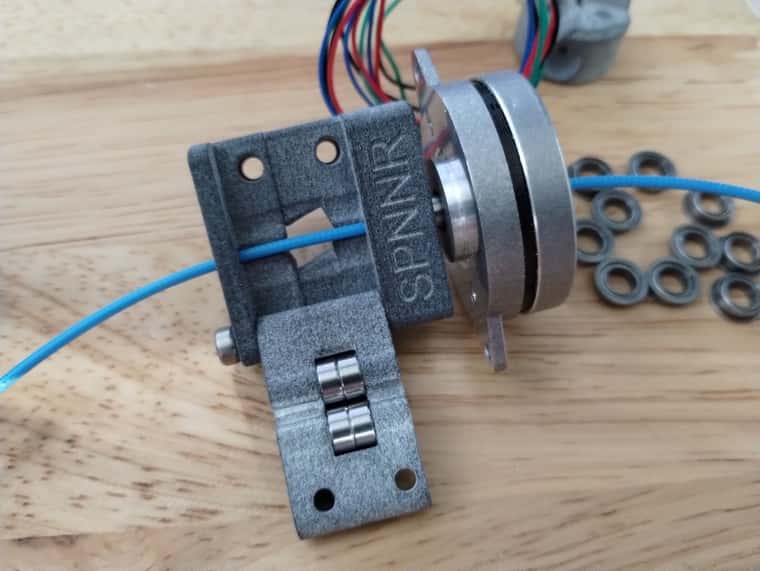

shoulder bolts finally showed up. guess its time to grind some bearings and make a roller on the lathe.

Best posts made by breed

-

RE: Hollow shaft extruderposted in General Discussion

-

RE: Hollow shaft extruderposted in General Discussion

Those rollers that were on funssor store on AliExpress a month or so ago finally showed up. They don't look anywhere near as bad as far as machining quality goes compared to the pictures. Id be hard to pressed to make better ones on the lathe. I'll send some pictures later today, gotta get to bed so I can watch some college football today.

-

RE: Duet 2 Hangprinter, 5-bar Scara, Polar, Rotary Delta kinematicsposted in General Discussion

@dc42 I vote get rid of them. Would much rather have more modern features on my production printers than a shorter path to an odd kinematic play toy printer.

-

RE: Hollow shaft extruderposted in General Discussion

https://www.printables.com/model/565908-screw-extruder

I put my old screw extruder design I had been working on a few years ago and an updated design made for a stepper motor that Ive been working on lately. Im gonna start working on it again, let me know what you guys think. def not as light weight as the VDE100, but was orginally intended to go on a smart effector on my Anycubic Predators. Also at one time I considered remote direct drive as the screw extruder is low torque high rpm and the zesty nimble and such were en vogue at the time.

-

RE: Hollow shaft extruderposted in General Discussion

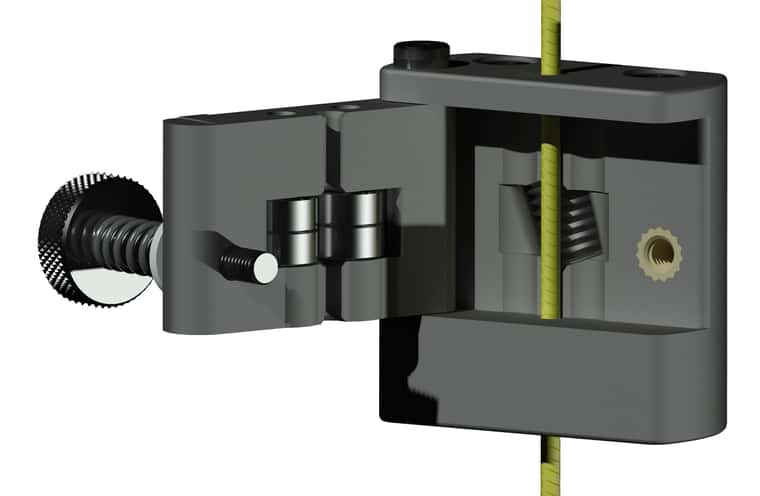

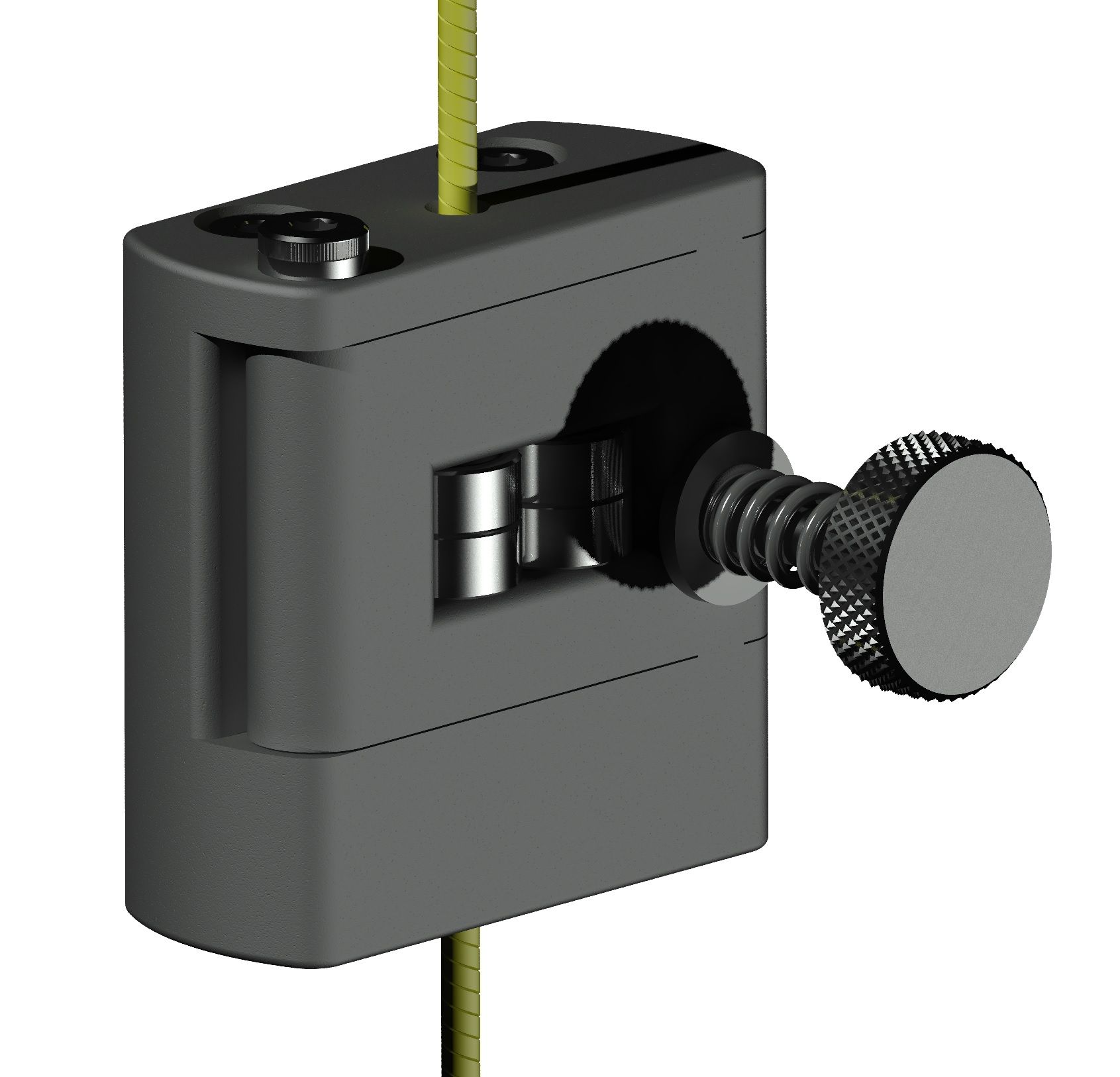

Been playing around this week in cad. 8mm roller would have to be made on a lathe. 683 bearings. Would make a 2mm lead 2 start thread on the filament. https://www.printables.com/model/573540-extruder-8mm-quick-release

-

RE: Monitoring of extruder head using laser distance sensorsposted in Third-party add-ons

@tylersuard closed loop steppers. The newer ones from mks work great. Everyone will tell you here to fix the printing problem first, which is fine on a 20 hour print. I print 100+ hours quite often on big machines, fixing the printing problem only goes so far. Id much rather have a completed print with a small blemish, that is still usable.

-

RE: Entry level Resin Printer Adviceposted in General Discussion

@cncmodeller most resin printers are the same. Almost all use chitu brand controls. Def get a mono screen or one of the newer dlp printers, mono prints much much faster. Suggest getting two tanks for which ever wash station you decide. Dirty tank and a cleanish tank. Remember once the ipa gets cloudy you can pour it into a glass jar and set it out in the sun. The resin will coagulate and can be filtered out through a coffee filter to be reused. I usually add some fresh in also. Cheers.

-

RE: My Delta Toolchanger - Finally printingposted in My Duet controlled machine

@itslikeboo I love this project. Hope to do something similar on one of my anycubic predators except with two smart effectors. Keep up the good work.

-

RE: 6 Axis linear Deltaposted in Firmware installation

@tkln very interesting. Think this could be the future if they ever get a good slicer.

Latest posts made by breed

-

Mostly 3d printed automated material system design.posted in General Discussion

https://grabcad.com/library/cycle-test-prototype-for-automated-filament-loading-system-1

Started working on a mechanical prototype of ams system similar to bambus. Hoping to set one up to just cycle back and forth thousands of times to find issues. Take a look and let me know what you guys think.

-

RE: Bed surfaceposted in General Discussion

@fcwilt Seems to stick. My brother is gonna cut it for me on the laser at work. Should know in a few days.

-

Bed surfaceposted in General Discussion

Does anyone know what type of steel is normally used for spring steel sheets? 400 series stainless?

-

Cdy v3 and hobby servos.posted in STM

I bought a mellow cdy v3 a while back to play with and never got around to putting it on a machine. I had an idea for a Bambu style ams a while back and I was thinking about printing some of the mechanicals and doing some testing. On the cdy can I connect a servo to say a fan output and use m950 s0 "fan1", as long as I have a separate 5v supply for the servo and tie negatives?

-

RE: Hollow shaft extruderposted in General Discussion

Those rollers that were on funssor store on AliExpress a month or so ago finally showed up. They don't look anywhere near as bad as far as machining quality goes compared to the pictures. Id be hard to pressed to make better ones on the lathe. I'll send some pictures later today, gotta get to bed so I can watch some college football today.

-

RE: Hollow shaft extruderposted in General Discussion

@tombrazier that's genius. Too fast for the bearings?

-

RE: Hollow shaft extruderposted in General Discussion

shoulder bolts finally showed up. guess its time to grind some bearings and make a roller on the lathe. -

RE: Hollow shaft extruderposted in General Discussion

@o_lampe I remember talking to you about that screw extruder. Are these the right size screws for that design? You had 3d printed the rollers correct to see what the looked like?