Z 0 is positive

-

Can you give us some more context to your method?

-

https://docs.duet3d.com/en/User_manual/Connecting_hardware/Z_probe_testing

Calibrate the Z probe trigger height

-

@Phaedrux said in Z 0 is positive:

Can you give us some more context to your method?

SEND ME MORE MATERIAL -

Hi Luca, what material?

-

; Z-Probe

M558 B1 P8 R0.4 C"io3.in+io4.out" H15 F1500 T12000

G31 P100 X0 Y0 Z-0.557

M557 R225 S100

-

How are you setting Z0 before measuring the probe offset?

How are you determining Z0 before creating the mesh? -

home

move z down to get 0

g92z0

A few g30 s-1 to see that it is same

open config.g

edit G31 line with offset

save and M999See to that no compensation is active M561

G29 -

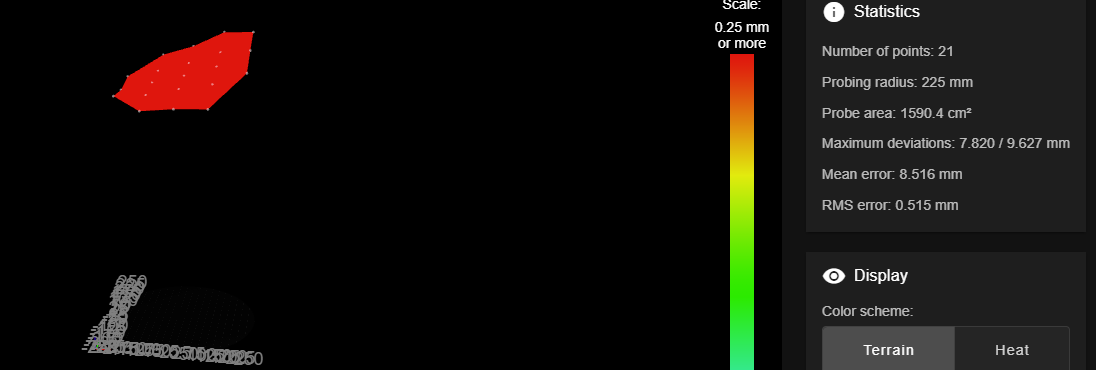

@luca-Massimiliano NO IT'S NOT ENOUGH I WANT TO SEE THE POINT QUOTAS OF YOUR PRINTING PLATE EACH POINT YOU SEE CORRESPONDS TO 3 CORDINATES OK?

-

-

-

@luca-Massimiliano EVERY POINT IS THE POINT WHERE THE PROBE BEATS OK FRIEND?

-

@luca-Massimiliano EVERY POINT IS THE POINT WHERE THE PROBE BEATS OK FRIEND?

-

@luca-Massimiliano FRIEND SORRY I HAVE TO GO NOW EXCUSE ME BYE

-

@luca-Massimiliano Phaedrux KNOWS MUCH MORE THAN I

-

@tecno said in Z 0 is positive:

save and M999

See to that no compensation is active M561

G29Try doing a single G30 at the center of the bed before sending G29 to create the mesh.

You should probably also redo your G32 first.

-

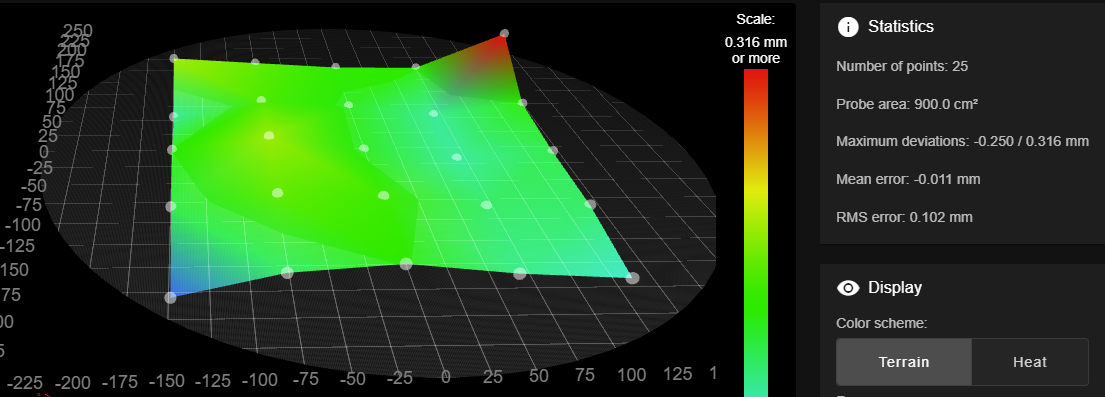

After a lot of tweaking this looks to be the best I can get.

Every adjustment of the plate (3-points) a G32 is a must, G30 and then G29.

Picture below is with 60°C heated bed.

New 8mm thick fine milled cast aluminium plate Ø600mm, what can I expect to get in flatness?

Cheers

Bengt -

8mm thick fine milled cast aluminium plate Ø600mm, what can I expect to get in flatness?

That’s a good flatness, except of the front/left and rear/right - hmmm - "corners"?. For a Delta, a square grid as you’ve pictured is inappropriate. See

M557: Set Z probe point or define probing grid for details. Instead of defining the grid by X/Y, use R to set a radius. -

@infiniteloop

M557 R225 S75 it is -

M557 R225 S75 it is

Within the radius of 225 mm, some points cannot be reached by the probe without mechanical problems. These are not related to the bed but probably to issues with your motion system - to spot these areas, narrow-down your mesh to an S value of 20 or similar. In the next step, you can either solve the issues (but maybe these are inherent to a Delta) or minimise the probing radius in order to get a proper mesh which merely represents the surface of your bed, excluding other factors. Else, you can’t use the result for mesh bed levelling.

-

Can somebody explain what @infiniteloop is trying to say as I can not grasp this?

@infiniteloop said in Z 0 is positive:

For a Delta, a square grid as you’ve pictured is inappropriate

@infiniteloop said in Z 0 is positive:

Else, you can’t use the result for mesh bed levelling.