Rounded corners with Pressure Advance

-

Hi,

I could use some suggestions on where to go from here.

Decided to try calibrate a new 0.8 Revo nozzle with PETG. I have been printing a 100x100x100mm cube with a single wall and no infill or top layers. I set the seam in the middle of the wall along the x-axis (towards the front of the printer).

PA = 0, I get a bulge in the seam. The corners look pretty ok, maybe a slight bulge.

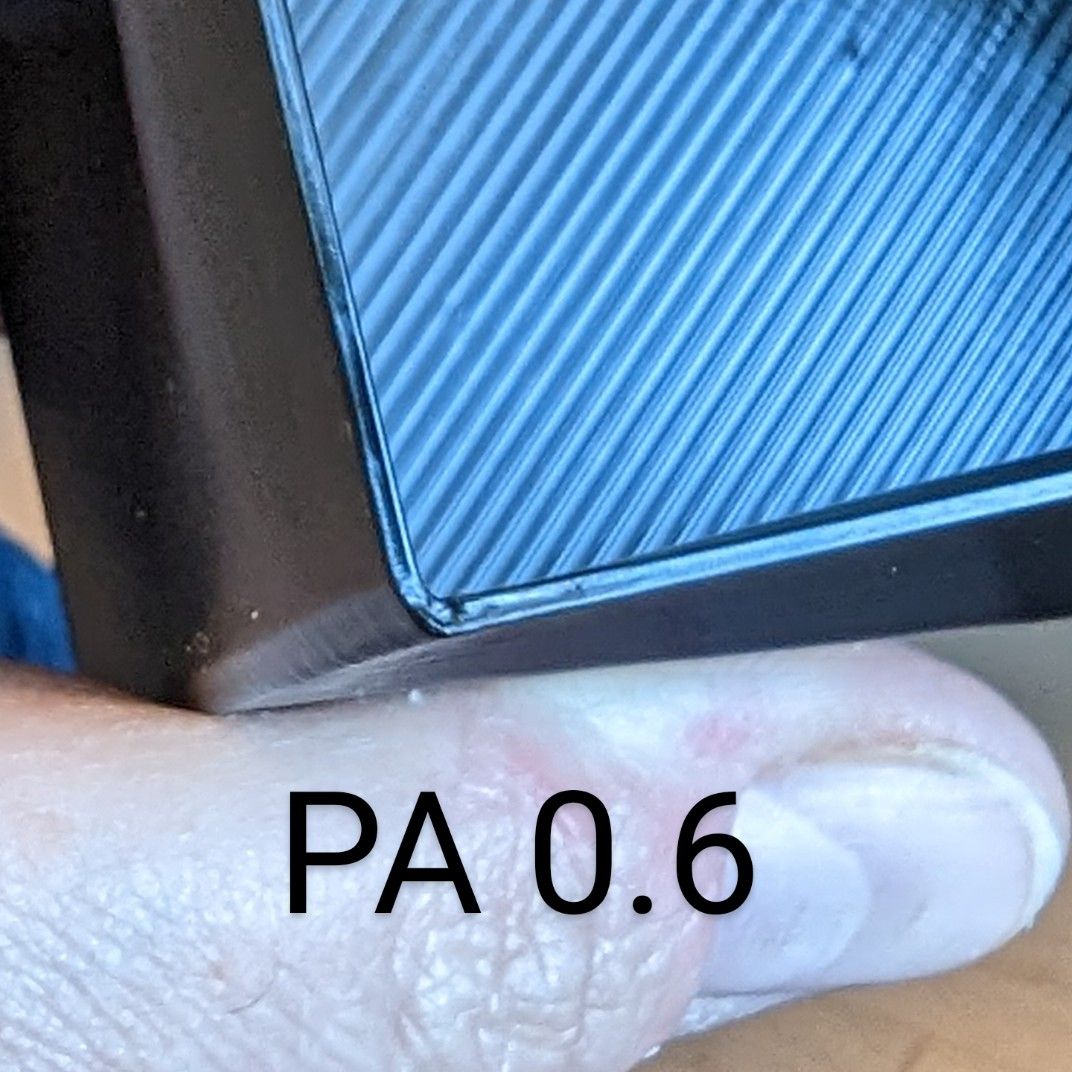

PA = 0.06 the seam is the prettiest, but now I got strangely rounded corners. Like they are being cut of too early.In between 0 and 0.06 I have to choose between rounded corners or bulge in seam. The inside corners look ok.

I did two tests with different acceleration and jerk increasing. Tested acceleration between 100 and 1300 and jerk between 150 and 2000 but nothing changed much, just slightly. 40mm/s is probably to slow to show much of a difference.

Could it be low quality PETG?

I'm levitating towards having crisp corners and having to live with a bulging seam.- Ender 5 Plus

- Hemera direct drive with Revo 0.8mm nozzle

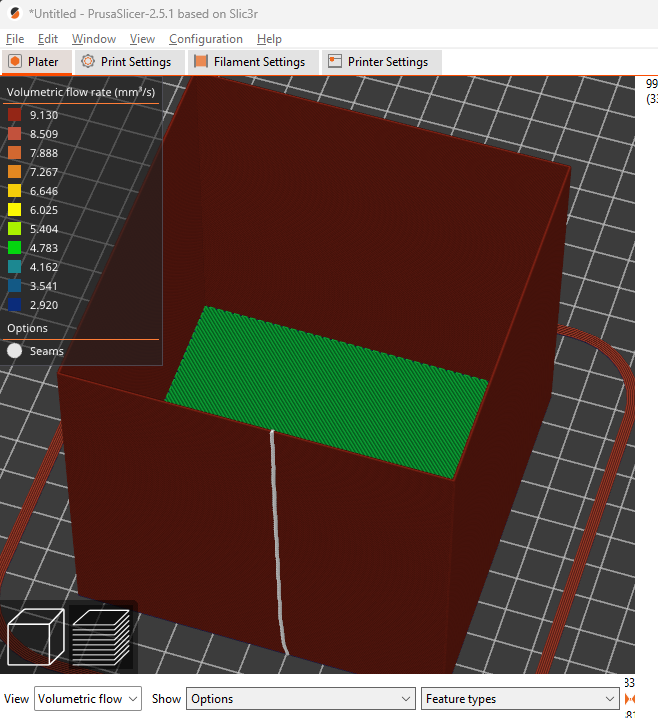

- Volumetric flow for is constant ~9mm3/s for whole print

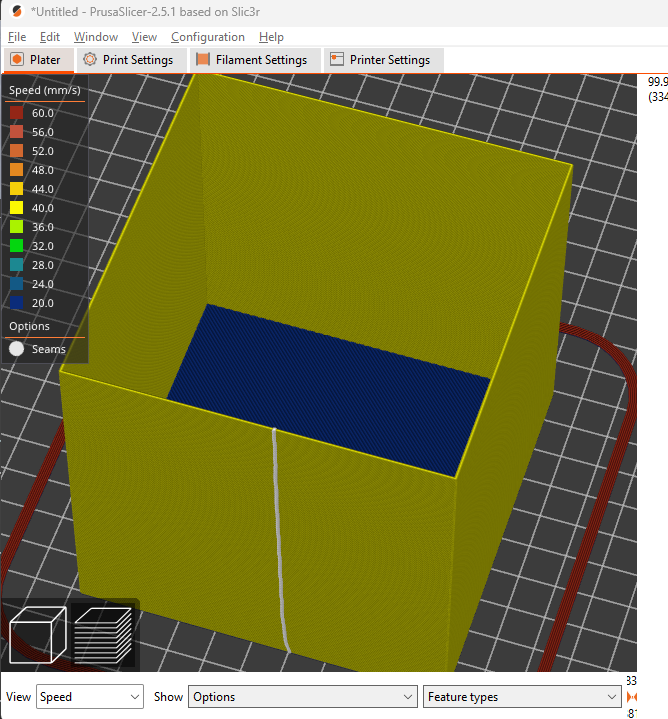

- Speed 40mm/s

- 0.3mm layer height

- 0.87 mm width

- All retraction has been disabled for tests

M203 X15000 Y15000 Z1200 E3600 ; Speed - set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E1000.00 ; Accelerations (mm/s^2) M566 X900 Y900 Z60 E3000 ; Jerk - gammel. brukt en stund nåAny suggestions?

-

@strips I believe it's related to the "constant flow rate" setting. Maybe PA works better with constant speed?

Trying to find the sweet spot without retraction is not helpful either IMHO. I think you'll have to start all over again, when retraction is ON.Just my 2 cents, hope you'll prove me wrong

-

Thanks. Since you often need less retraction when using PA, I thought to do an initial PA calibration without any retraction. Then calibrate retraction and eventually a new PA calibration to see if it changes in any way.

I usually have retraction set between 0.2 - 0.4, so it's not a lot anyways.

In reality I have a constant speed of 40mm/s in all moves in the test which coincidently gives me a constant flow with only a single wall. At least according to speed and volumetric view in Prusaslicer.

-

@strips I would focus more on the corners with the single wall box test.

In a normal print, the seam comes on a travel move from the infil and internal perimeter, not just the external perimeter jumping up. So if you tune for the seam on the single wall test, you are not really tuning for a real use case.

You can then tune retraction etc for the seams on a more representative test once you're happy with your corners PA -

Thanks! That sounds sensible.

-

Do you have a direct drive setup? If so, you should look at very low PA settings, we're talking between 0.015 and up, up to like 0.3 at most.

I'm running 0.03 for example for a 0.4mm nozzle