Hollow shaft extruder

-

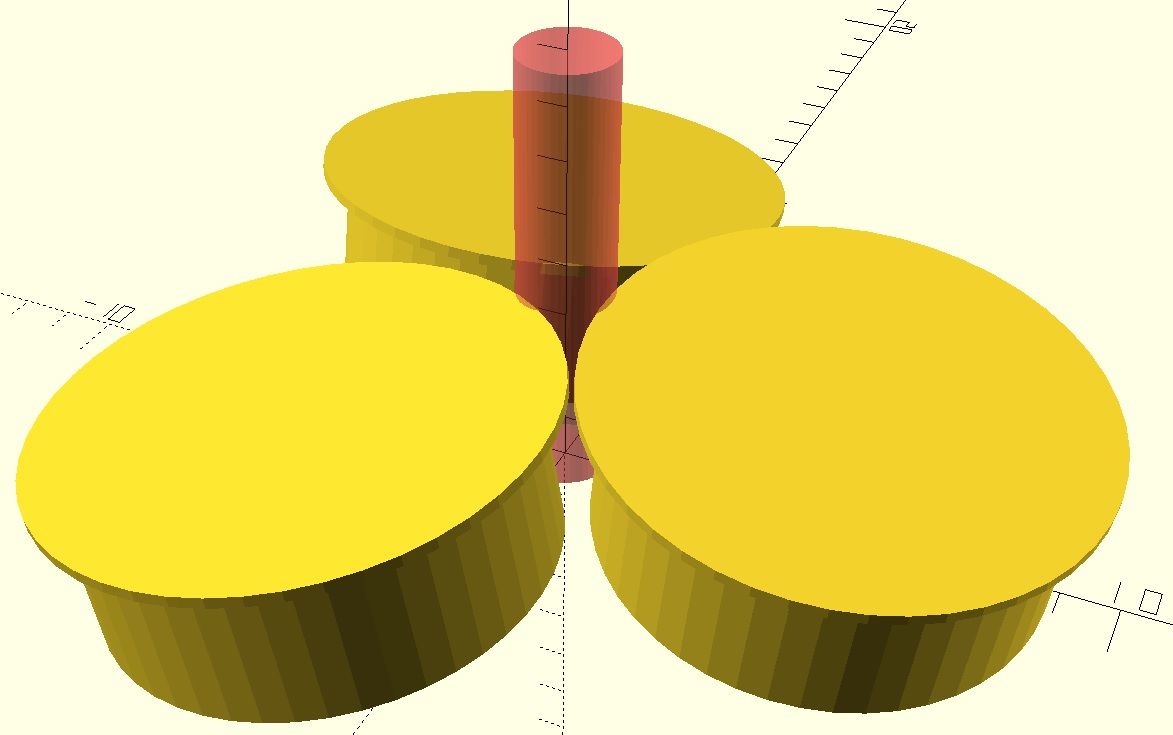

I made my first tilted VDE-100 carrier yesterday and tried to put some 10mm bearings on. Surprisingly they don't really cut it.

I tried several different setups, with or without washer underneath, 1,2 or 3 flanged bearings with flange up or down.My impression is, that it would work better with 8mm bearings, so I wrote another sketch to draw the bearings instead of the carrier.

Now I can see much clearer, how deep the flange would cut into the filament at a given offset and tilt-angle.

As a sidenote: the idea to push the bearings up with a ring lever will need extreme force, but one step at a time.

-

@o_lampe Yes, 10mm is too large. The bearings interfere with each other. I am now using MR85ZZ flanged bearings and a MF95ZZ pressure bearing. Even the MF95ZZ is a bit big and I have shaved the corners down a little to prevent interference.

And while I'm talking about bearings, ABEC rated bearings are a really good idea. Rq3 uses ABEC-5 and I have been using ABEC-3.

Your carrier appears to have all three bearings cutting the filament at the same height. This will create three grooves very close together and experience shows that that tends to just grind up the filament. I arrange my two knife-edged bearings so they run in the same groove.

Also note that the axis of rotation of each bearing needs to be positioned so that it comes to its closest point to the axis of the filament at the exact height where the knife edge cuts the filament.

-

@nikscha said in Hollow shaft extruder:

did you print mihaidesigns extruder test piece? I'd be curious whether any patterns show up there.

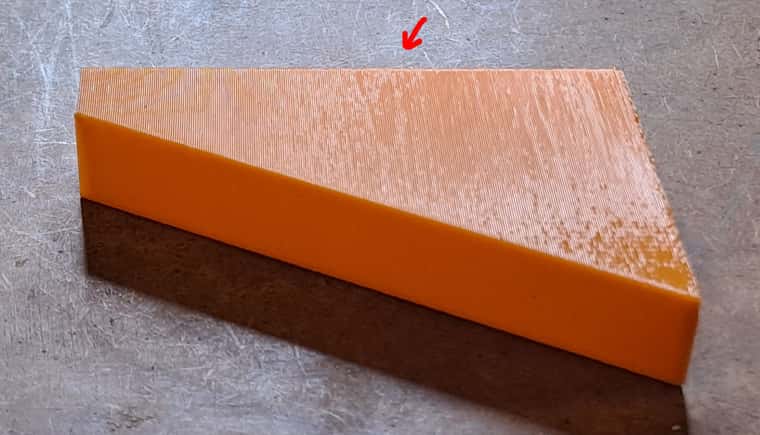

Here's a picture.

There is a very slight pattern but I found it really difficult to photograph. I have indicated with an arrow where you can see it in the photo.

-

@tombrazier said in Hollow shaft extruder:

Your carrier appears to have all three bearings cutting the filament at the same height. This will create three grooves very close together and experience shows that that tends to just grind up the filament

I agree, there is a downside with this arrangement, but each bearing has two opponent bearings and the filament has no way to move or flex.

I'm under the impression that the flanged bearing idea is not the best solution.

Maybe it's better to have three rotating shafts with blades at different heights and the ends of the shafts run in bearings.

These shafts could easily be CNC'd on a lathe and would cost next to nothing (thinking big) -

@o_lampe rq3 tried lots of those kinds of variations, including diamond dust glued to the bearings. Flanged bearings won handily. The problem with stacked blades is that there is only one point along the axis of the bearing/shaft that is the correct point for interfacing with the filament. It's the point I mentioned above where the axis of the bearing/shaft is closest to the axis of the filament. I would have to stop and think now to remember why that was so important, but I remember it was important.

[Edit: But do experiment. I experimented a lot as well and repeated a lot of rq3's findings. But there's always scope for finding something we've missed.]

-

@tombrazier

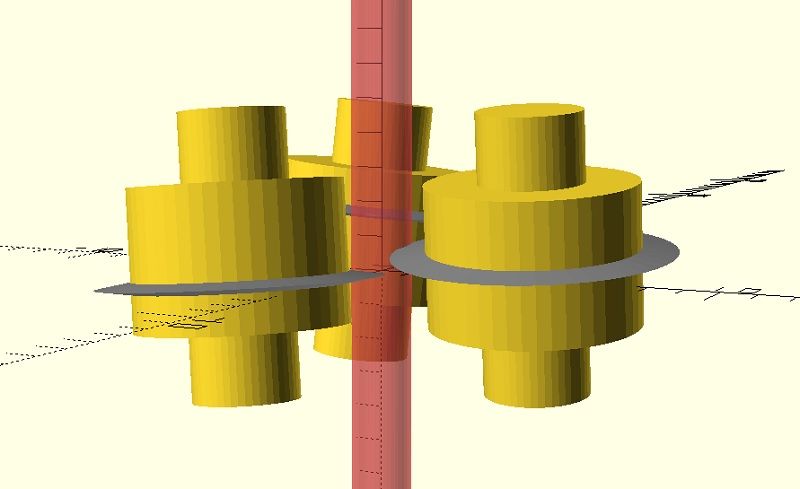

I quickly sketched something that looks like it could work. The blades are each 0.5mm different in height. That should be correct, when they are 120° apart and the advance is 1.5mm? Somehow it looks wrong, but it's just a matter of adapting the formula.

-

@o_lampe I see I misunderstood you. I thought you meant multiple blades per shaft.

The extruder you show with three blades is pretty much what I have been using for the last year, except I only have two blades and the third bearing is just a plain one that acts as am idler for the two blades. And, yes, the vertical spacing would be something like 0.5mm each for a 1.5mm thread pitch. For me this was really easy to implement using flanged bearings once I worked out an easy way of grinding the bearings. But shafts with blades as you suggest would work just as well and I agree it's more a matter of what is easier to manufacture.

-

@tombrazier said in Hollow shaft extruder:

That was my expectation too - mainly informed by how grip works on ice skates. The closer to vertical the side of the blade is, the more grip there is. But the thread widening effect acts like a plough wheel. It's not grip that is the problem but rather that a furrow is being ploughed through the plastic. You can actually see this and it really does look like ploughed earth with a little ridge piled up parallel to the thread. I am now wondering whether different plough wheel profiles would have different ploughing effects. I notice plough wheels tend to be thin. So if I don't actually want to plough, what if I used a more wedged shaped wheel?

I see. Do you have a macro shot of the filament after it has been extruded? Would also be interesting to see the difference between filament that has been extruded with a "load" applied vs without. Probably the pitch will change then? And/or the amount of "plow"? Maybe even steps/mm will change depending of load/resistance from the nozzle?

I also don't understand why you only grind one of the 3 bearings, wouldn't all 3 be better? Is there some mechanical constraint? Or is 1 just enough for the purposes of the extruder?@tombrazier said in Hollow shaft extruder:

It's printing now.

Awesome!

Edit: I just saw that my question about the 3 cutting bearings was answered already!

-

@tombrazier that's basically non-existent. I'd say the VDE-100 passes with flying colors.

-

@o_lampe Neat! But how would you attach the blades? Or make it from a single piece?

-

Maybe replacement cutting wheels for this sort of tubing cutter could be used:

-

Just wanted to jump in as the video says that the motors was special-order.

There seems to be both nema 8/14/16/17 motors available with hollow shafts with a 3mm ID.

The nema 8 comes in at 50g weight while still providing 1.5Ncm.https://www.omc-stepperonline.com/dual-shaft-nema-8-hollow-shaft-stepper-motor-bipolar-1-5ncm-2-12oz-in-0-49a-20x20x27mm-8hs12-0494h

https://www.omc-stepperonline.com/nema-14-hollow-shaft-stepper-motor-bipolar-18ncm-25-5oz-in-0-8a-35x35x34mm-14hs13-0804sh -

This one even comes mounted on a ball bearing: https://www.aliexpress.us/item/2251832765359999.html?gatewayAdapt=glo2usa4itemAdapt

-

@mrehorstdmd at 33mm diameter, I think it’s probably a bit big! Normal ones are 15mm, with a 3mm bore. But a good idea and worth testing, I’d think.

Ian

-

@nikscha said in Hollow shaft extruder:

that's basically non-existent. I'd say the VDE-100 passes with flying colors.

It's slightly easier to see with the naked eye. I suspect it's actually caused by the motor, not the VDE-100. It's a very old motor and the hole I drilled down the shaft is a little off-centre.

Do you have a macro shot of the filament after it has been extruded? Would also be interesting to see the difference between filament that has been extruded with a "load" applied vs without. Probably the pitch will change then? And/or the amount of "plow"? Maybe even steps/mm will change depending of load/resistance from the nozzle?

I do have a picture somewhere but can't lay my hands on it just at the moment. In a recent experiment I found that the thread pitch would compress by approaching 50% when I attempted a filament feed rate of 7.5mm/s on 1.75mm filament. And, yes, this affects steps/mm. But you have to be printing with a large layer height and wide line and going fast to need 7.5mm/s. The same happens with all extruders but it happens earlier with VDE-100.

This reminds me about some other things I wanted to mention to you: It would be interesting to see how much feed rate is reduced in your extruder due to filament distortion. There will be some effect, but given the number of teeth contacting the filament at once the expectation is that it will be less than for the VDE-100. And the other thing is that rq3 and I both concluded in our experiments that pushing filament is a different thing to pulling filament. Pushing causes compression whereas pulling causes stretch and these may interact differently with the drive system. It is, of course, a lot easier to measure how much weight an extruder can lift but in the end it is the pushing force that is key.

-

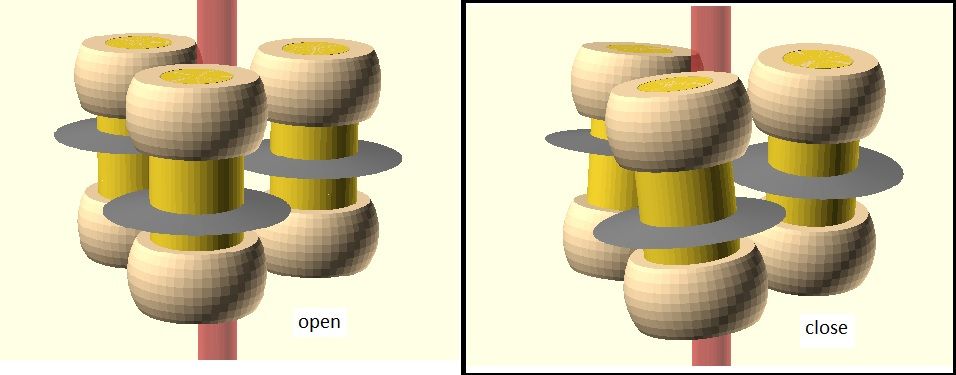

I have added ball-joints to the fila-rollers. The idea was to have a seperate upper and lower half of the carrier and with a little twist, I can unwrap the rollers from the filament and pull it out.

Because the twist also changes the depth of cut.//edit It's sadly not enough unwrapping, maybe if I also spread them apart while twisting....

-

@o_lampe would it be possible to prepare the filament (eg near the filament holder) with grooves in advance, so the requirements are lower for the extruder (only Z movement needs to be exact), or is this patent protected? (I cannot remember the printer name, with special filament gear rod at one side)

-

@JoergS5 There are more and more people using push-pull dual extruder motors. If the stationary motor would already cut the thread (with a beefy NEMA17 motor) it would help for sure. Just wondering, if the threaded filament would still fit through common PTFE tube?

I'm impressed of the pancake motor weighting only 28 grams. It would be a good candidate then (with a hollow shaft) -

Guys, this is a can of worms with hollow shaft.

-

@tecno A few years ago, that's what they said about geared extruders, too.

I see it as a challenge. Maybe we'll end up with a ballscrew-extruder? I've drawn some sketches already