Hollow shaft extruder

-

@o_lampe The rods are mounted at an angle so the center of the rods will be closer to each other than the bearings.

PS I have sent a message to Funssor.

-

@tombrazier Making a bearing-holder to grind three bearings at once doesn't sound too hard? I hought, there was a guy in discord channel working on it?

-

@o_lampe Deadlock is working on it. His initial design has too much friction.

I reckon we need lots of ways of getting these bearings as different people will be happy with different solutions. e.g. pretty much anyone can already use my method but most regard it as too fiddly. Some will be happy to use a home-printed jig. Others will just want to buy the part and not be too worried about cost.

-

@tombrazier My concern is that the chinese guys will be tempted to use cheap labour child-slaves to grind your bearings by hand. We'd have to buy 10pcs. to find three good ones...

-

I ordered a set. I'll take pics and let you know what they measure. If you get someone to commercially make sharpened flange bearings for the vde that would be awesome.

-

@o_lampe I remember talking to you about that screw extruder. Are these the right size screws for that design? You had 3d printed the rollers correct to see what the looked like?

-

@o_lampe That is a very reasonable concern and a good point.

-

This post is deleted! -

@o_lampe did you publish your Stepper-to-BLDC-via-simpleFOC solution somewhere? People are interested in it for other use cases.

-

@breed The version I made was a forked design called "skrewder". Their rollers have an OD of 8.2mm.

From the aliexpress picture it's hard to tell such a small difference, but you will know soon. -

@oliof I've only tested the BLDC-sherpa version with magnetic sensor. (see attached .txt)

My next test will be a torque controlled BLDC as remote pusher and a NEMA08 as direct drive as pacemaker on the effector. It's not published anywhere, yet.

I expect best of both world from this combo: strong Bowden tube motor and smallest direct drive motor.

ESP32_stepDIR_24V.txt -

shoulder bolts finally showed up. guess its time to grind some bearings and make a roller on the lathe. -

I've just posted a brief video featuring a bearing grinder I am working on. [Edit: credit to user DeadLock on the 3D Printing Discord server whose ideas I have borrowed.]

-

@tombrazier It has potential. I never thought of using the threaded collar of the grinder for that.

I pictured a fixed grinder on a 2040 extrusion and the bearing holder slides on a linear guide.Any news from LDO regarding delivery?

-

@tombrazier that's genius. Too fast for the bearings?

-

@o_lampe Using the threaded collar to feed the cutting edge was entirely something I stumbled across. But it works well.

Oliof says the motors are schedule for delivery this week.

@breed Speed didn't seem to be an issue even at top speed. But there is more driving of the bearings than cutting of the edge going on. If I move the bearings so they are more off-centre from the mandrel shaft then the motion of the cutting disk over the flanges should have a greater radial component over the flanges and, therefore, result in more cutting.

-

I vaguely think someone asked me to grind some bearings for them some time back, but can't remember who. If it was anyone here, can you remind me?

-

@tombrazier it was me

-

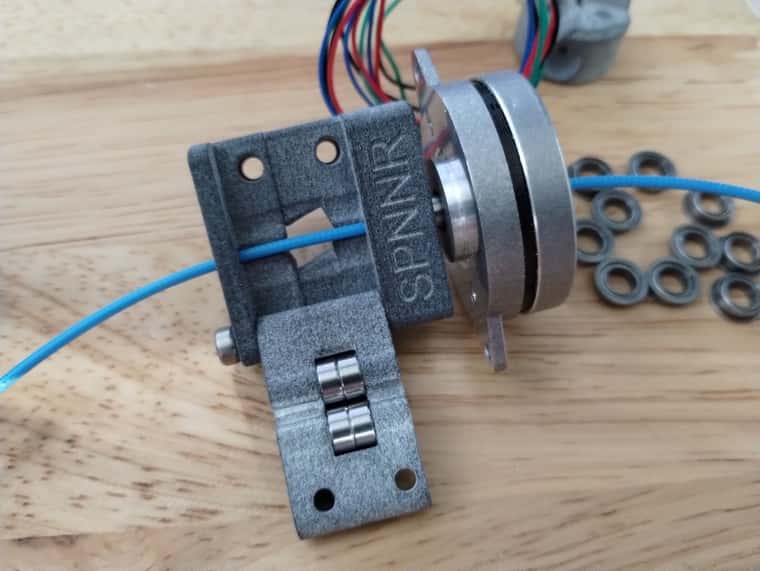

My NEMA08 pacemaker setup.

It got pretty tall, but saves a lot of weight compared to other DD extruders.

Bracket and motor alone weight 58grams

-

@o_lampe Looks really good. The filament should be constrained as soon as possible after leaving the extruder. Can you get some PTFE tube in there?