Chamber circulation fan control

-

@travasky said in Chamber circulation fan control:

I'm in the process of retrofitting and rebuilding a Stratasys SST1200. Ive chosen the Duet3 6HC since Im familiar with the older Duet 2 boards from previous builds. This machine uses two resistive heating elements which Ill control with an SSR via a standard output channel (OUT9 in this case). However, any time the heaters are on, the chamber fans must be running also. This blows air over the heaters which sit in side compartments and then into the main chamber via two air knifes. I'm familiar with thermostatically controlled fans but in this situation the temperature isn't the deciding factor as to whether or not the fans should be running. Instead, if the heaters are being used, the fans must be on at full power. What is the best way to implement this? FYI, these 4 fans draw more current than any of the other devices so I've planned to assign them to OUT 0.

Why not drive both the fans and the heater SSR from out0 ? That way they will always be on together.

-

@travasky I'd recommend taking a look through this thread: https://forum.duet3d.com/topic/12647/another-stratasys-uprint-retrofit/41

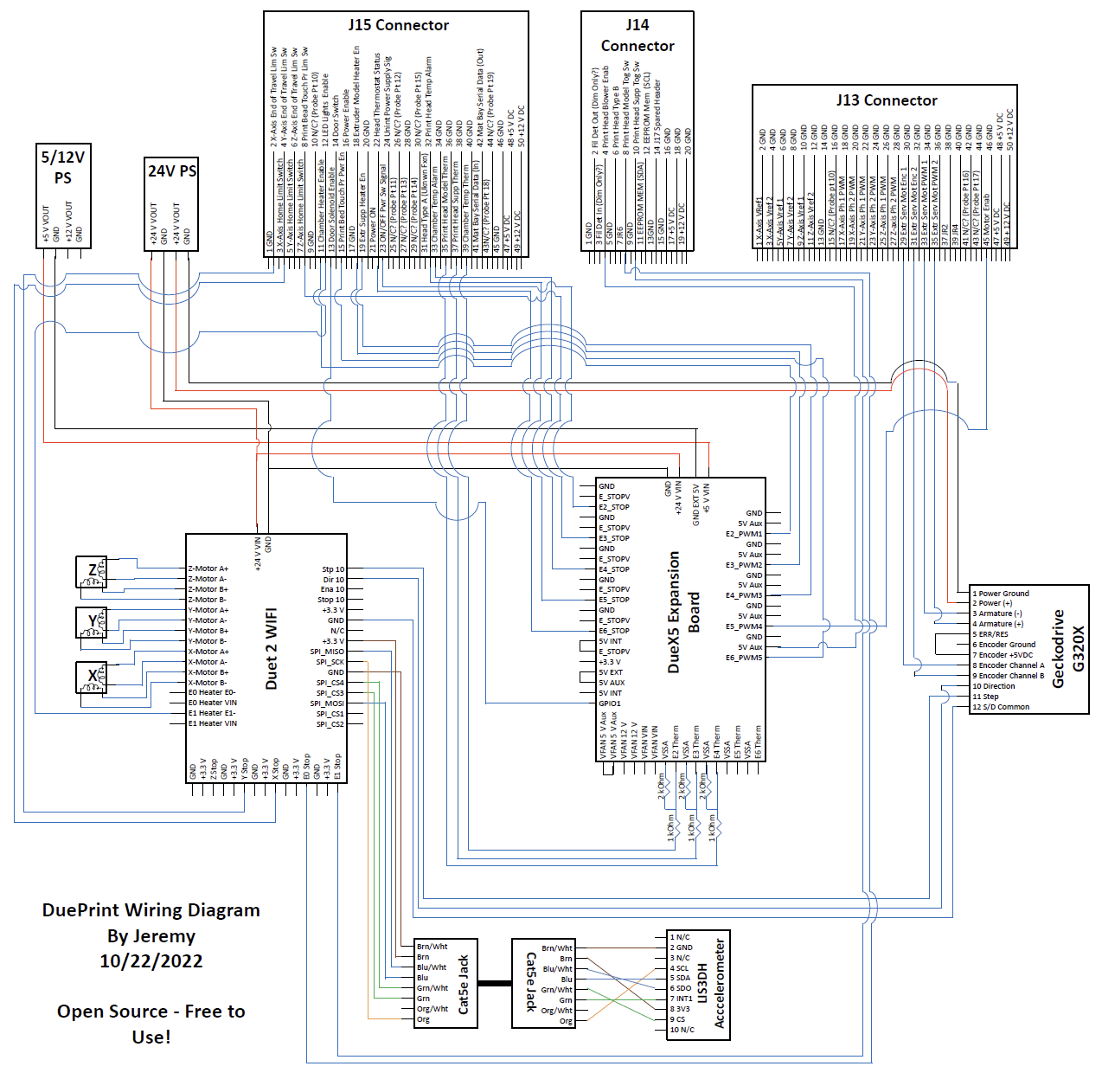

And the associated Hackaday project (under files there is a wiring diagram): https://hackaday.io/project/186419-dueprintWhile this retrofit replaces the Stratasys SBC and control board with a Duet 2 + Duex, it retains the Stratasys PDB. For the most part the Duet and Duex interface with the PDB, so you don't have to worry about the specifics of the existing components when connecting the Duet boards.

I have a BST1200, and a near term goal is to perform a similar retrofit but with the Duet 3 ecosystem (in my case, other projects keep getting in the way!). One issue I believe, and this is just from counting up I/O from the wiring diagram), is the Duet 3 6HC is one I/O short to be a direct swap for the Duet2+Duex. It may be possible to reassign/repurpose a heater channel or 5V PWM output to fill this gap, but I haven't looked into too much detail yet.

If you read through the project linked above, they drive the extruder DC motor via a Geckodrive G320x - but this actually then goes to the PDB's L298P full bridge. To do a similar setup with the Duet3 system, you'd likely need to go 6HC->1XD->G320x, so with the 1XD you could likely make up that previously mentioned I/O gap. I'm looking at alternative ways of driving the DC motor (Which I highly recommend keeping in the system), but I'm also not there yet

Duet2/Duex wiring

-

@travasky I use one 500W Stratasys heater in my printer. I have the fan wired in parallel with the heater so that when the heater turns on, the fan runs. Those heaters will get scary hot without the fan(s), but you don't need a lot of air speed over them to keep them at safer temperatures. I used a 220VAC fan and run it from 117VAC. It turns slowly and quietly and moves just enough air without causing a hurricane inside the printer that might mess with the print.

-

@oliof The hardware side of things is my strong point but the software side, less so. Is there a good guide that would get me started down this road?

@soare0 The fans are DC, the chamber heaters are AC. But the bigger issue is that the chamber heaters will need to be controlled with a PID loop so there are moments when the fans would be off if the heaters are off. The air still should be circulating during the whole print.

@dc42 As above, different voltages and I don't want the fans to turn off when the heaters have reached temp or between "bang bangs".

@sebkritikel I actually did read through that thread a few weeks ago. There's a surplus of I/O on the Duet board - at least for my design. I ended up just doing a full on gutting of the machine and Im doing all new stuff. I've only retained the chamber heaters and fans, LED lights at the front of the chamber, and part cooling fan. The idea of doing all the work to interface to old and hard to find hardware just didnt feel worth it to me. Because Im using the SBC Ive added a 10" touch screen with some buttons below that control the material cartridge drive motor and solenoids. Ive also designed a circuit that controls the cartridge latching system. Ill probably design new cartridges that allow fast and easy material swaps. My current build only has a single extruder but once the machine is up and running Ill start on a dual extruder model with tilting hotends similar to the original design (mechanically actuated instead of servo driven like you see in other hobby machines).

@mrehorstdmd how are you getting around the fans turning off / pulsing when the chamber hits the target temp? In the original machine fans were on 100% of the time the machine was on. In my case I'd like the ability to control them if I decide to print a material other than ABS for example. I added a heated bed to give me flexibility on materials instead of the plastic build plate that was passively heated on the original. Seems like a shame to not be able to use or not use the fans at will.

-

I read a bit more about the daemon.g file and the object model. Again this is way over my pay grade but could I get away with just monitoring whether or not the chamber heaters are active and the turn the fan on if so? Like this:

if heat.heaters[2].state == active

M106 P3 S1Where the chamber heater is heater 2 and the chamber fans are fan 3

-

@travasky

I too have a chamber heater that needed a fan. I do not consider it safe to run the fan control from the printer controller unless there is some sort of safety that is preferably totally independent of the controller. In my case I opted to turn the fan on whenever the heater is on (turned on by the power to the heater). My heater is a PTC heater so it has a bit of a built in safety.

Another option is to run a second fan that is software controlled that you can run during the entire print to circulate the chamber air. -

The heated side chambers have thermal fuses. I’m not sure what the ratings are but Stratasys deemed them appropriate.

-

@travasky, that is the proper way to go .....

-

Just opened up the sides to check the PN. Here they are: https://www.selcoproducts.com/product/12-disc-thermostat-manual-reset-om-250

-

@travasky said in Chamber circulation fan control:

@soare0 The fans are DC, the chamber heaters are AC. But the bigger issue is that the chamber heaters will need to be controlled with a PID loop so there are moments when the fans would be off if the heaters are off. The air still should be circulating during the whole print.

Then add a small time relay (not mechanical, of course), set with the same period like your cicle, or such. If a little higher, will be no issue. I assume that something with a 555 will do, or even a simpler circuit. Probably you will find some little boards, wicj would do, like this one:

Probably needs adapted, and the SSR or whatever will replace the relay.

I hope I understood your needs, though... I would not use daemon.g but only for big cycles, like 1 min or more, and only if no other cheap choice, or reliable choice, but maybe I am wrong on this. Still, for sure it works with it. -

@travasky said in Chamber circulation fan control:

@mrehorstdmd how are you getting around the fans turning off / pulsing when the chamber hits the target temp? In the original machine fans were on 100% of the time the machine was on. In my case I'd like the ability to control them if I decide to print a material other than ABS for example. I added a heated bed to give me flexibility on materials instead of the plastic build plate that was passively heated on the original. Seems like a shame to not be able to use or not use the fans at will.

I don't. The fan turns on and off with the heater. The printer is tall and the heater/fan located at the bottom of the machine. I only heat to 50C when printing ABS and don't want a lot of air movement at the print, so for my printer, it's fine that the fan is low powered and doesn't spin continuously.