Out of Sync for sync motors (same Axis)

-

@jay_s_uk

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.3 (2021-06-15)

Duet WiFi Server Version: 1.26we did define 4/2 Z motor, depending on a specific machine

M584 X3 Y1:2 Z5:7:8:9 E4:0 -

@maor3degem-co-il best to update to 3.5.2 then. and post a config for the actual machine with the issue

-

-

This post is deleted! -

@maor3degem-co-il best update the firmware and try again

then if it happens again, grab an M122 output after the occurance -

@jay_s_uk

thanks

will do so and keep you posted -

-

Any macros being called during the print? Anything running in daemon.g?

In your first post's video the right-hand motor looks to be turning 16x faster than the left, so, that's no random number. Wonder if code is being called somewhere that is changing your microstepping or steps/mm?

-

@Maestro

I alsothought this could be,

but. this 2 motor define as the same axis. so cannot be done.

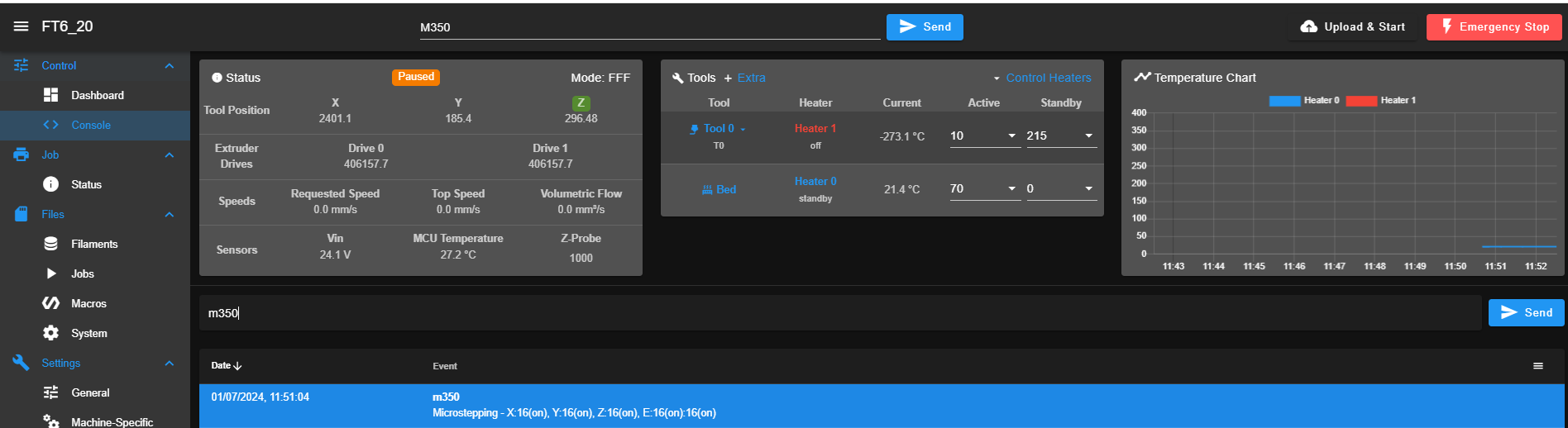

and also I check the m350 and it remain OK as define in the config

-

@maor3degem-co-il Sorry you are having issues. I notice that the failing axes are usually plugged in to the DueX board. In your first crash it was Z that lost sync, when the following was defined:

M584 X3 Y1:2 Z5:7:8:9 E4:0In the second, it looks like X lost sync, and dropped on the Z axis that knocked the bed out of level. Were the Z motors also turning at different speeds? The M584 was:

M584 X5:6:7:8 Y3 Z2:1 E4:9As you have been using quite old firmware, and this has not been reported before, we do not think this is a firmware bug. Most likely is interference on the ribbon cable, that carries the SPI commands that set up the drivers, as well as controlling them. It could also be due to a poor earth wire between the Duet and Duex, causing ground issues on ribbon cable between the two boards.

Please check the following:

- Check there are no other wires running close to or across the ribbon cable between the Duet and Duex. Ribbon cables are quite susceptible to interference; wrapping them in foil can help, but better to remove any close source of interference.

- Check that the DueX board is properly grounded. See https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/DueX2_and_DueX5#power-wiring

If that doesn't help, please take a picture and post it, showing how your Duet and DueX boards are wired.

Ian

-

@droftarts Hi

thanks for your help,

in the second, the Z motor also turning different length , the same symptom as with the X axis. and the Z connected to the main board...in addition we face this problem with a few machines we have (5) and it is occur also in the main boards drivers.

please advice what else can help us to solve this problems

Regards

Maor -

@maor3degem-co-il said in Out of Sync for sync motors (same Axis):

in the second, the Z motor also turning different length , the same symptom as with the X axis. and the Z connected to the main board

It is possible interference on the SPI bus via the ribbon cable, or poor ground between the Duet and DueX, could affect the drivers on the main board as well. Please look at my previous message for advice. Please post a picture of the wiring if that doesn't help.

in addition we face this problem with a few machines we have (5) and it is occur also in the main boards drivers.

Maybe they are all wired the same way? What is different about these 5 machines compared to the other 15?

please advice what else can help us to solve this problems

At the moment, I don't have any other theory about what is wrong based on the information you have give, or I'd tell you.

Ian

-

@maor3degem-co-il

we have 15 machine that look pretty much the same.

we used them for 4 years without any problem like this,

this start happen in the last 4 months...can heavy dust cause this?

-

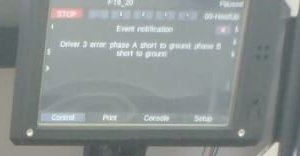

@maor3degem-co-il I also note on your last image there is an error on the PanelDue:

I think this says "Driver 3 error: Phase A short to ground phase B short to ground". Is that correct? Did the Y axis wires cut when the carriage fell?

can heavy dust cause this?

Do you mean on the Duet boards, or on the mechanical components? However, I don't think either would cause these kind of problems, because something is causing the configuration of the driver chip to change without the firmware knowing. Though it wouldn't hurt to use compressed air to clean off the boards, if there's a lot of dust on the boards. If there's dust in the mechanics, I'd expect skipped steps rather than a change in the driver configuration.

After 4 years, it's probably time to check/replace wiring, check contact especially in screw terminals, etc.

Ian

-

@droftarts

The driver error is due to the carriage fall cut the wire.by the way, the machine is on pause right now and I can see the problem of the motors. if I will restart the machine the problem will go a way till next time.

and before restart the is no evidence of changing in the configuration

-

@Maestro

I double checked it and

the motor doesn't move 1/16 cycles than the other

both motors are define in the same axis so it is impossible to define different micro stepping for each motor. and when I typed M584 the machine return 1:16 micro stepping for those X axis drivers/motorsRegards

Maor -

@maor3degem-co-il @Maestro

I double checked it and

the motor doesn't move 1/16 cycles than the other

both motors are define in the same axis so it is impossible to define different micro stepping for each motor. and when I typed M584 the machine return 1:16 micro stepping for those X axis drivers/motorsRegards

Maor -

@maor3degem-co-il

I'm not sure what you mean by "the motor doesn't move 1/16 cycles than the other"? Irrespective of whatever values are read from firmware or anywhere else, that first video you loaded shows one motor moving 1/16 the speed of the other, at least within the resolution of the video to quantify.Even it if is not possible to deliberately set different microstepping for 2 motors on the same axis in the firmware, that doesn't negate @droftarts's point that the drivers themselves could potentially decide that they've been given a different value due to noisy instruction sets.

-

@maor3degem-co-il Sorry you are continuing to have issues.

To reiterate, I believe the problem is caused by the interference on the SPI bus causing one or more stepper drivers to reset its configuration, usually on the Duex, independently of the firmware. I think there are three possible reasons for this:

- Interference caused by poor grounding between Duet and Duex boards, causing a potential difference in signalling on the SPI bus. Check/replace the grounding between the Duet and Duex, as described here https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/DueX2_and_DueX5#power-wiring. Check for good contact of power and ground wires, especially in screw terminals.

- Interference caused by other wires. Check there are no other wires running close to or across the ribbon cable between the Duet and Duex. Ribbon cables are quite susceptible to interference; wrapping them in foil can help, but better to remove any close source of interference.

- Interference caused by ESD (Electro Static Discharge). You mentioned dust in the environment. Is it a particularly low humidity time of year? This could cause more static shocks that usual. How is the rest of the machine grounded? Is the hot end grounded (we recommend doing this)? Have you changed to a different type of filament that may be more susceptible to static build up?

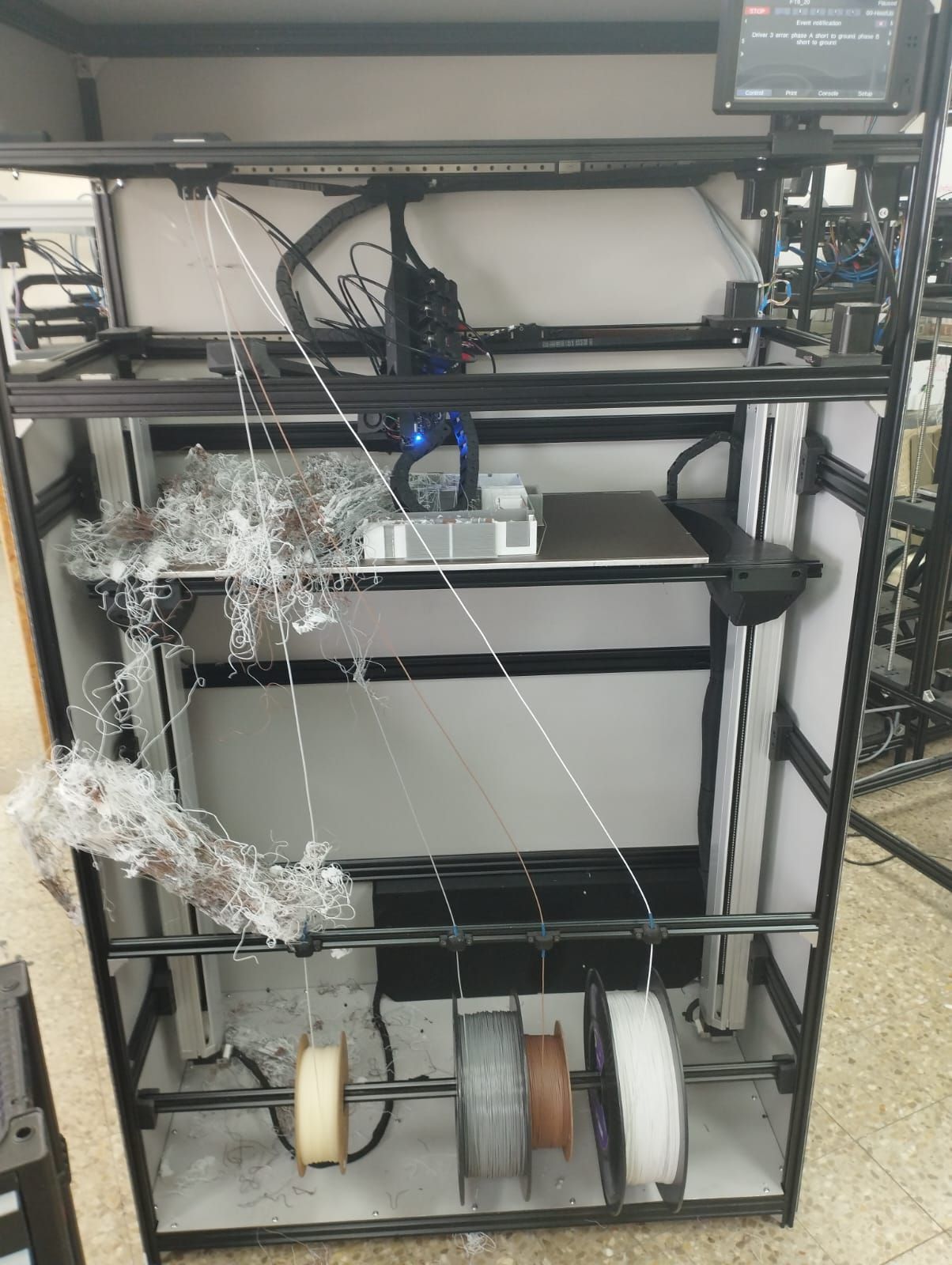

As I asked before, please post pictures of the wiring cabinet, and the wiring around the Duet and Duex in particular.

Ian

-

@droftarts

Hi.another event.

it is certainly looks like 1 driver out of 4 of X axis lost his microsteping definition.

[M350 Lost for 1 of 4 X axis drivers.M122.txt config.g M350 Lost for 1 of 4 X axis drivers.mp4

attached is a video nd config + M122 output.

please advice.

this happen with multiple FW version (3.3 + 3.4.5 + 3.5.2)

this happen with drivers from the duet/duex; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 20:45:39 GMT+0300 (Israel Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"FT6_7" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet M584 X3:4:5:6 Y0 Z8:7 E1:2 M671 X-220:740 Y175:175 S15 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis ; Drives M569 P0 S0 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes backwards M569 P2 S1 ; Drive 2 goes backwards M569 P3 S1 ; Drive 3 goes forwards M569 P4 S0 ; Drive 4 goes backwards M569 P5 S0 ; Drive 5 goes forwards M569 P6 S1 ; Drive 6 goes forwards M569 P7 S0 ; Drive 7 goes forwards M569 P8 S0 ; Drive 8 goes forwards M569 P9 S0 ; Drive 9 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80.00 Y80.00 Z1440 E400 ; Set steps per mm M566 X900 Y900 Z24 E1200.00 ; Set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z720 E7200.00 ; Set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z500.00 E10000.00 ; Set accelerations (mm/s^2) M906 X1600.00 Y1200.00 Z1600.00 E750.00 I30; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; switch motor M950 P0 C"spi.cs1" M950 P1 C"spi.cs2" M950 P2 C"spi.cs3" ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X750 Y350 Z750 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;M591 D0 P3 C"e0_stop" S1 R70:130 L24.8 E1000 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, ;3mm detection length M591 D0 ; display filament sensor parameters for extruder drive 0 ;M591 P3 C"e0_stop" S1 D3 L3 E4 ; filament monitor connected to E0_stop ; Z-Probe M558 P1 C"zprobe.in" H5 F500:50 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P500 X-10 Y25 Z0 ; set Z probe trigger value, offset and trigger height M557 X15:700 Y30:320 p20:14 ; define mesh grid M376 H50 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"e0temp" Y"thermistor" T100000 B4580 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S400 ; set temperature limit for heater 1 to 275C M308 S2 P"e0temp" Y"thermistor" T100000 B4580 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e0heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S400 ; set temperature limit for heater 2 to 275C M308 S3 P"e0temp" Y"thermistor" T100000 B4580 C7.06e-8 ; configure sensor 3 as thermistor on pin duex.e2temp M950 H3 C"e0heat" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 3 M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H3 S400 ; set temperature limit for heater 3 to 275C M308 S4 P"e0temp" Y"thermistor" T100000 B4580 C7.06e-8 ; configure sensor 4 as thermistor on pin duex.e2temp M950 H4 C"e0heat" T4 ; create nozzle heater output on duex.e2heat and map it to sensor 4 M307 H4 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H4 S400 ; set temperature limit for heater 4 to 275C M308 S5 P"e0temp" Y"thermistor" T100000 B4580 C7.06e-8 ; configure sensor 5 as thermistor on pin duex.e2temp M950 H5 C"e0heat" T5 ; create nozzle heater output on duex.e2heat and map it to sensor 5 M307 H5 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H5 S400 ; set temperature limit for heater 5 to 275C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0:1 H1 F0 ; define tool 0 M567 P0 E1.0:1.0 M563 P1 D0:1 H1 F0 ; define tool 1 M567 P1 E1.0:1.0 M563 P2 D0:1 H1 F0 ; define tool 2 M567 P2 E1.0:1.0 M563 P3 D0:1 H1 F0 ; define tool 3 M567 P3 E1.0:1.0 M563 P4 D0:1 H1 F0 ; define tool 4 M567 P4 E1.0:1.0 M563 P5 D0:1 H1 F0 ; define tool 5 M567 P5 E1.0:1.0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P3 X0 Y0 Z0 ; set tool 3 axis offsets G10 P4 X0 Y0 Z0 ; set tool 4 axis offsets G10 P5 X0 Y0 Z0 ; set tool 5 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C G10 P3 R0 S0 ; set initial tool 2 active and standby temperatures to 0C G10 P4 R0 S0 ; set initial tool 2 active and standby temperatures to 0C G10 P5 R0 S0 ; set initial tool 2 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss