Duet 3 mini 5+/FYSETC Big Dipper on FFCP/Flashforge Creator Pro

-

Hi, again, today I overcame my fear and started to crimp.

All in all for FFCP you need to crimp

- all four fans 1.board fan 2. cooler fan 3.extruder 1 fan 4. extruder 2 fan

- five stepper motors

- 3 end stop switches (x/y/z)

- hotbed thermistor 4 pin to 2

- LED strip because the board uses 3pin connector for that instead of 4 pin, but I am not yet sure that the original LED strip is supported

Today I crimped stepper motors and 2 endstops

Stepper motors are easy to crimp, because you only have to check the right order of the cables.

Endstops have 4 pins, but you have to use a 5 pin connector and use only three pins out of them, because Big Dipper/Duet has only one ground. I crimped both grounds together, but if that's wrong please point it out before I plug it in)I used these two schemes for that

https://www.geeetech.com/wiki/index.php/Mighty_Board#Interface_Layout

https://wiki.fysetc.com/BIG-DIPPER/#3d-modeland I only needed xh2.54 connectors, thanks for the advice @Exerqtor

Crimping process is a new thing for me, so I had to watch some videos to undestand the idea)

For those like me, in a few words, you have to use a crimper tool like SN-2549 and squeeze the tail leaving the front part with a locklng tab intact. Also the idea is to squeeze the tail to fix the cable insulation, so the exposed part of the conductor shouldn't be too long. But I have yet to check my crimping skills, after I finish that process.

Also I accidentaly damaged end stop cable, because I thought it was a bad cable, but it turned out I am the one who is bad at electronics) I guess they make a special GND cable without insulation to take off interference from y and z axis of endstops. For some reason x endstop cable uses another shielding and there is no exposed wires there. So i ripped z axis cable apart and now I am waiting for a new one from ali.

In the meantime I'll finish with other components.

I also checked my adapter design for the Big Dipper

It is ok, but I will have to use only 3 out of 5 screws, because some holes are below the board and the board might touch the screws.

Also I guess I'll have to turn the board in such a way that stepper driver chips are not directly in the line of sight of the board fan. But I think the space between the board and the case would be enough to ensure some airflow. Also I think to add heat sinks, although FYSETC says that they are not necessary.I also ordered an extender for type-c, to make access to the board easier.

As far as WiFi is concerned, I don't want to make holes, so I'll try to design a holder that will be placed on top of the holes for old reset button and mightyboard data port. But for that i will need to start printing, so it'll have to wait) -

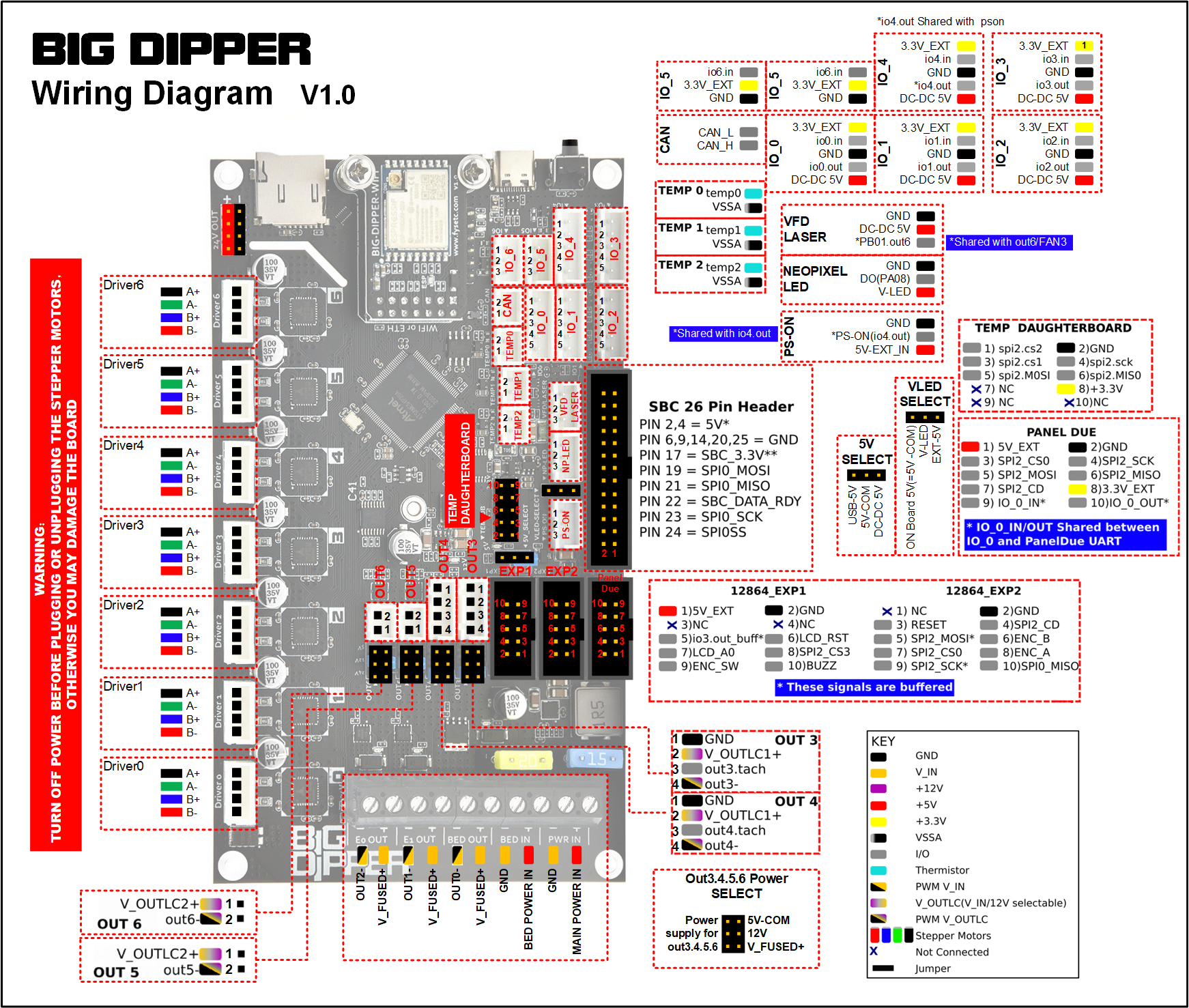

the endstops need to be wired individually. See the diagram

.

. -

@oliof Hi, thanks, I don't understand what you mean though.

Actually forgot to mention where I plan to put which cabel. Maybe that will clear things out

- So with drivers everything is obvious

- Endstops according to docs under the scheme are going into io_0-io-6 ports.

MightyBoard endstops Mech 1.3v have 4 pins (signal, GND,GND, 5v)

So I decided to use three out of five pins for each endstop based on this doc https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_endstops

signal == io_in

gnd1 + gnd2 == gnd

vcc/5v == DC-DC 5V - Fans will go into out_3-out_6 ports

+positive cable will go into - V_OUTLC1+

-negative cable will go into - out- - Board thermistor will maybe go into temp0-temp2 and again 4 pins should become 2 pins. But according to mightyBoard pinout it has

HB_T

GND

GND

5v

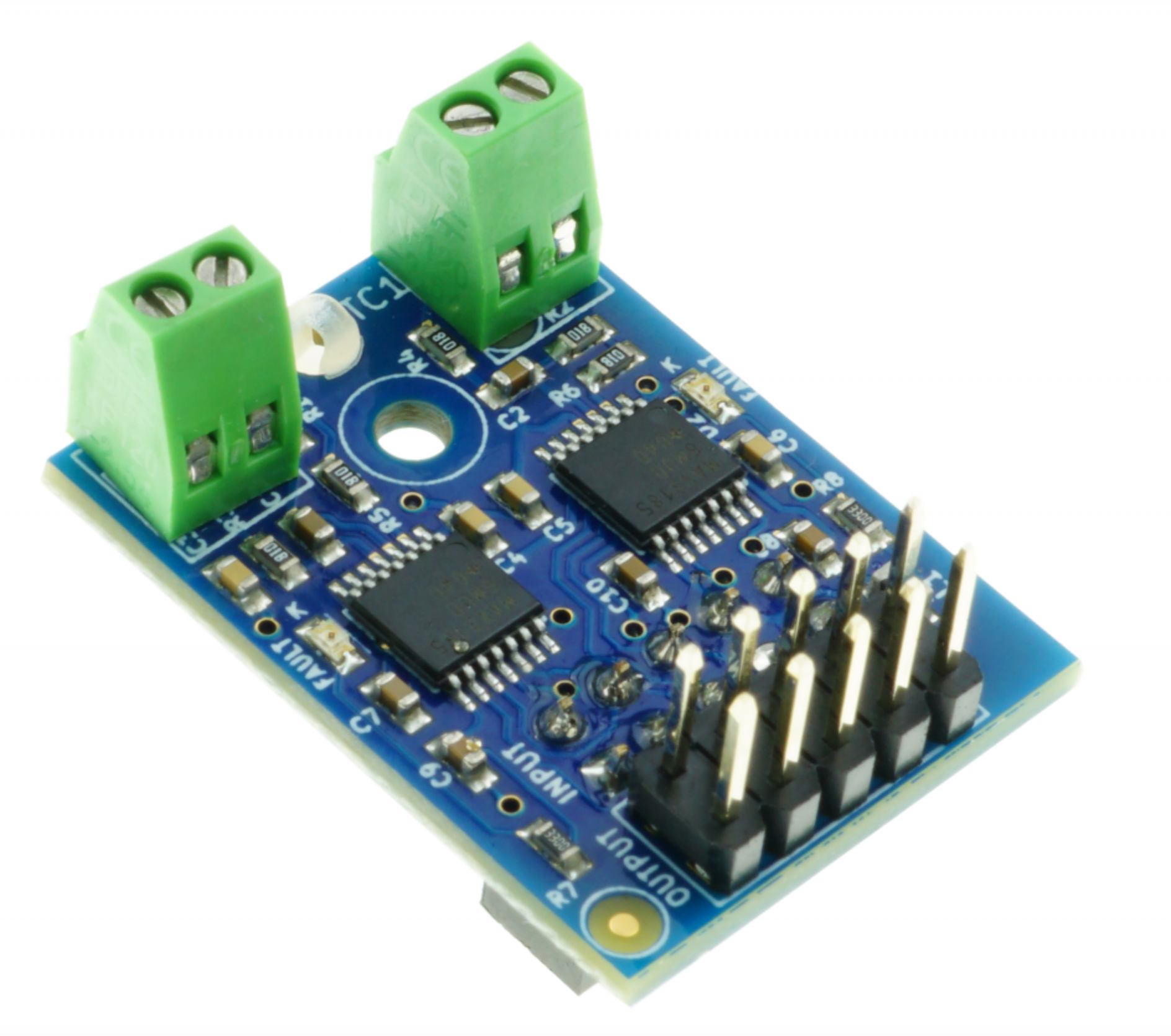

And what is bothering me is that it needs some power and maybe should go into one of the io ports and not temp - I have a daugherboard for extruder thermocouples

- Power cables go where they should.

But I have only two cables for the bed,

so I guess

+positive will go into - BED POWER IN

-negative will go into - OUT0- - And LED should go into NP_LED I suppose, but it is hard for me to understand what pins should go where.

According to mightyboard doc the LED has 4 pins

24v

LED0

LED1

LED2

And Big Dipper has 3

GND

DO(PA8)

V-LED

I guess V-LED might be the power pin. But other pins seem incompatible

-

looks like the mechanical endstops have gnd and signal for the end stop, and gnd and vin for the activity LED. I don't know if its advisable to tie gnd together in this case as vin for the led may interfere with signal. I'd personally forego attaching the LED.

-

@Inlinebrother NP Led is for Neo pixel LEDs and not related to individual dumb LEDs.

-

Hi, some updates

I received an endstop cable

And yesterday, after a month or two found some motivation to start checking how it works

found some motivation to start checking how it works

So here is the list of what is checked right now

Power applied via standard for FFCP cables is working OK

I can connect to WiFi via Big Dipper when 24v is applied OK

(though you can't use USB 5v and 24v interchangeably to configure WiFi, because you have to move the selector physically. So if you want only to connect to USB and configure WiFi you have to move selector. If you want to use 24v and have a working WiFI you have to return the selector to the default state)

XYZ motors are moving when command is sent via WiFi OK

XYZ endstops are flashing when triggered OK

(though I don't know how to check whether endstops are working as expected before I try to home axis)Next steps

check fans

check thermistors

check heaters

Then close the case and try to configure the print -

Next update:

Extruder Fans OK

Cooling Fan (with ability to control air flow from 0 to 100) OKNext steps:

Forgot to crimp board fan cable TODO

Fix wrong wiring of the Bed thermistor TODO

Have to recrimp x axis motor cable TODO

check thermocouples are working when there are no config errors TODO

and heaters

(found a thread about bed thermistor here - https://forum.duet3d.com/topic/7285/flashforge-creator-pro-heat-bed-wiring/2) -

Next update:

-

By using the thread above now I see the bed temperature via a thermistor OK

used first two cables out of 4 (white and green in my case) -

Config from this thread helped me to turn on thermocouples (though i had to downgrade them to thermocouple-max31855 from thermocouple-max31856) OK

-

board fan working OK

-

extruder heaters are working OK

-

bed heater is not working, I'll check what's wrong next time TODO

-

Also I need to close the printer TODO

-

LEDs are not working and I don't think I am going to fix that in the nearest future NOT_HAPPENING

I might replace the screen with the one from FYSETC TODO -

Fix config issues that i can come across TODO

-

And finally print something TODO

-

-

Hi, everyone, if you are reading this, then I....

Finally finished assembling the printer after the upgrade)

-

I managed to home all axes OK

-

Added a fysetc 12864 screen, though it needs an adapter OK

I used the menu made by jadonmmiller

But I'll have to update the UI because this one is only for 1 extruder setup -

Drivers are doing their job, I hear almost only fans) OK

-

Figured out why the bed was not heating, it has a separate power input, and I had to buy another cable and crimp it OK

-

For now I skipped BLTouch sensor installation, because I don't want to make it even harder.

-

I started to configure the printer

And it seems that I'll have to read Gcode docs and learn Gcode, because it is everywhere

From screen menu and configs to printing instructions -

At the moment I have to find Gcodes to load/unload filaments and check that extruders directions are correct TODO

-

Then I'll have to configure Cura TODO

Somehow I used the printer without Gcode knowledge before that)

-

-

So I found gcodes in docs to load/unload filament

Then I had to change some configs for extruder drives

And now I got a problem with thermocouple board because there is interference from stepper motor cabelsIt seems that Flashforge fixed that issue in their version of mighty board, because i did nothing to the cables other than changing connectors

I have a 0.2v daughterboard and I think in 0.2v there was no capacitor

according to this thread adding a capacitor helps https://forum.duet3d.com/topic/1270/thermocouple-issues/10@dc42 Hi, sorry to tag you, but can you please confirm that in the daughterboard 0.2v there was no capacitor?

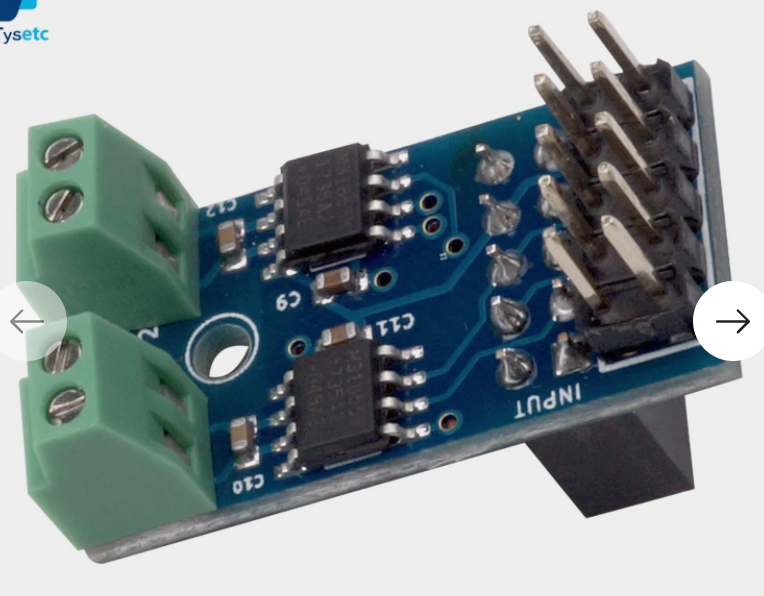

As far as I see from the picture of the daughterboard on the official site, the new version has some extra components on top of it

mine

from the site

And is the process the same for the 0.2v board?

- Take 4 capacitors

- find a ground plate

- solder capacitors to each pin and to the ground

-

Ok, I found your answer for the same question here

So i think one of the ways to fix that is to get the wire out of the casing -

But moving the thermocouple wires away from the other wires didn't help

Only one of the thermocouples for the right extruder now is working correctly, but i can't say exactly what helped, maybe i crimped it better. Although it still can catch the interference from the other thermocouple, even if using it alone does not provoke interference

They are still near the drives on the head, and i think that is where they pick this interferenceI wonder if using a thermistor will help

Flexion extruder allows to install it, and the board has ports for temp sensors -

recrimping didn't help, i think I'll have to go with the thermistor

that way i will not need a daughterboard and i guess that might help -

Captain's log

Installed and configured thermistor NTC 3950

Now I don't see 2000 degrees when extruding or retracting filamentBut my printer shuts down in a minute after that and then it is trying to restart over and over again, until I turn it off and turn on again

-

It seems that @dc42 helped me again, even without saying a thing)

I found my answer here https://forum.duet3d.com/topic/15897/duet-wifi-resetting-part-way-through-prints/30

I disabled endstops, and it seems that the problem is solved

Though I need to wire the endstops properly -

@oliof I think you are right, I didn't understand you at first) thank you)

-

Sooo, I did recrimp endstops

Thought now it is ready to go,

connected Cura via plugin OK

Started to heat the bed

After the extruder fan started to work the printer started to restart again

Then in a few minutes, after the printer cooled down, I thought I'll try to change some settings for fans

But the printer began to restart in an idle mode. I did nothing, and it started its disco.Now I don't know what can be the problem

Maybe something should be done to a board fan frequency, that is the only thing working when the printer is idle -

Ok I started from scratch

I think the problem was with the board loosely fixed, it might have touched some parts of the case

I also checked all the wires and reinserted them, trying to fix them as tight as possible

Now it seem to workStarted the test print, I'll write an update after that

For now I hear the sound of silence and it is great

I'll have to change the coordinates though, the print started on the corner of the build plate -

This post is deleted! -

Finally it is working

Though I need to adjust tool offsets a bit more

And I also had to change the cooling fan number in cura settings for every extruder to the pin number of the fan (in my case fan #3)

And I need to try dual extruder printingThank you all who helped me achieve this.

Hope my story will help somebody)I'll publish my design for the Big Dipper holder and my configs a bit later.