An extruder to turn a spool

-

I think you need a dancing arm mechanism..

http://www.pffc-online.com/webexclusives/7076-tension-control-dancer-0409

when the extruder pulls, it lifts the arm off a switch, maybe the switch closes a relay, car windscreen wiper motor turns the spool, arm lowers, hits the switch and stops the motor...

quite easy...

unless better bearings work.

-

@dorro1971 Nice!!

-

You will probably need a device like the one above to feed the extruder. Otherwise you have to know the radius of the remaining filiment on the spool to calculate the correct number of turns to get the right length. I built a stand where the spool sits on two rollers on the floor, and the filiment runs through some PTFE tubing to the top of the printer then to the extruder .

-

@phaedrux @dorro1971 @v0i9viper

right now it is sitting on one of my metal beams supporting my printer. it goes through the center of the spool and it just sits there. (yes its direct drive) As of now we are not using any bearings but if you have any pics or ones that are like that i would take a look at it because as of now ours look like this:

Thanks,

Bennett Drakas

-

I'm using a setup like this.

The spool hub is from an openscad file that is configurable to fit your spool and bearing. It's a little springy so it fits a vieriety of sizes plus or minus a few mm. The one shown is for a very small spool hole but it can generate larger as well. The bearing is a standard 608 on a 8mm smooth rod. There are a lot of parametric spool holders out there though.

But there is basically no friction with this setup. It unspools very easily. To counteract the tendency to unspools too easily there is a small block secured to the frame with PTFE tube running all the way to the extruder without being attached. Enough filament is uncoiled that it doesn't cause any motion at the spool other than the gentle pull of the extruder. Retractions are absorbed by the coil and don't effect the spool either.

-

@phaedrux

Could you send me a pic of what holding the spool up? i see some of the metal piece there but not the whole thing.

Thanks -

Sure I'll try and get a new pic shortly.

Right now it's pretty low tech. It's just a 18 inch long piece of smooth rod wedged into some printed uprights that are actually a spool holder stand that I didn't like using the right way because it kept the spool in the way of the extruder when at the back of the printer. Now it's hanging off the side of the frame.

-

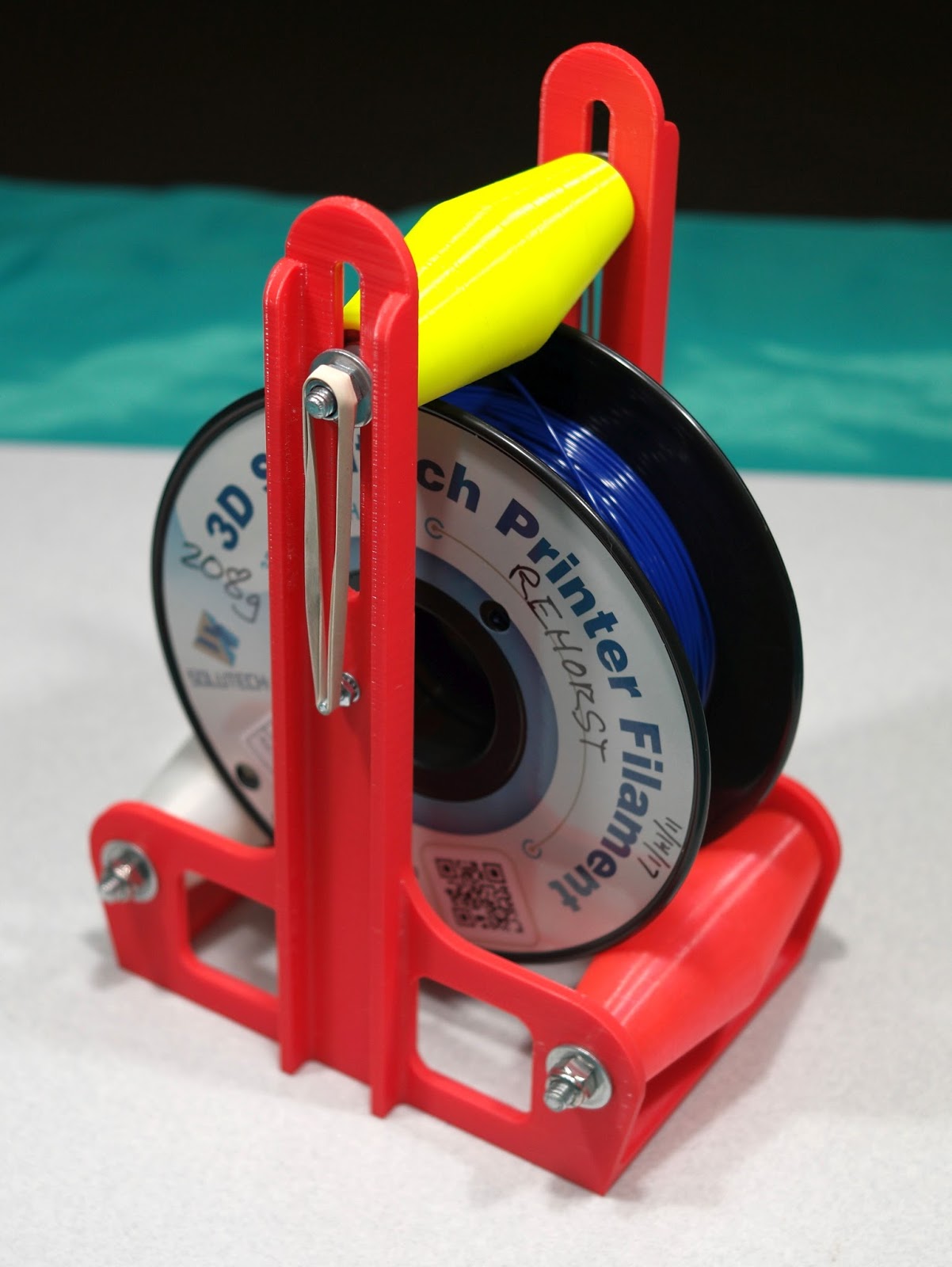

Hopefully that makes it a bit more clear.

The hub uses this Thing https://www.thingiverse.com/thing:2334107

Those red uprights are supposed to be spread apart and the rod is supposed to sit on top of them in a groove, but like I said, then it gets in the way of extruder carriage sometimes. This was my ghetto solution to get me up and running and it's worked so well I haven't bothered to mount it differently.

-

@phaedrux

So the rod is only connected at one side right? Is it all counterbalanced because with a heavier spool like with our 3 kg spool i don't know if it would be able to hold just with that. -

Yeah in your case with such a heavy spool you'll probably want to use a threaded rod that can be properly mounted to something solid. It doesn't necessarily need to be supported on both sides, but that might be easiest.

Something like this might work well. https://www.thingiverse.com/thing:1000323

That was going to be my replacement if the current setup didn't work out.

-

@phaedrux

We aren't using the t Slot beams all we have is 1 inch aluminum tube. So that one would be hard to get to work. Do you have any other files you saw that might work? -

Not off hand that would work with tube. But you could probably rig something up if you get creative.

-

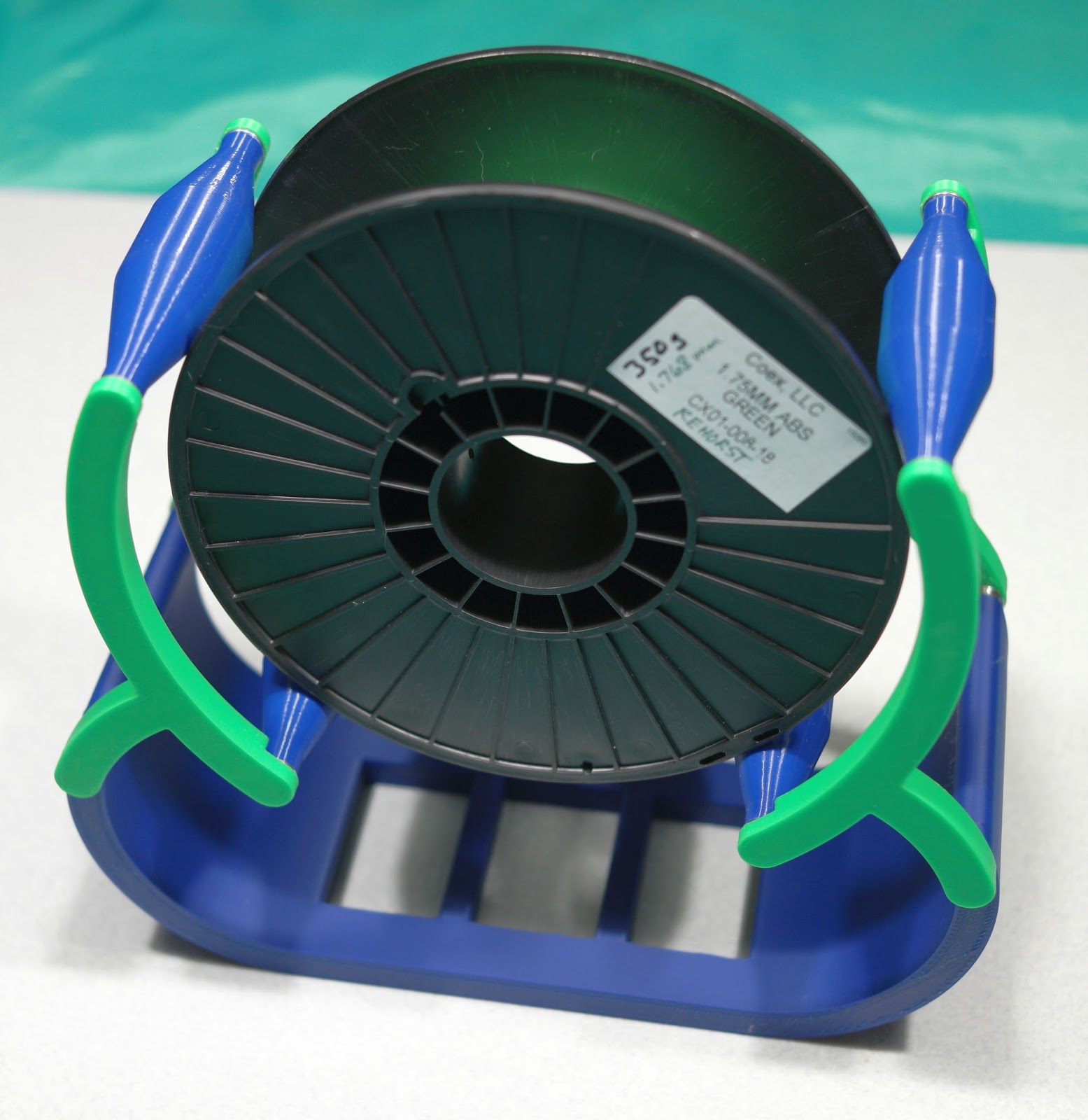

I use one of these on my printer (but only with 1 kg spools- it could easily be scaled up). The spool sits on two rollers with F608 ball bearings and a third roller comes down on top of the spool to prevent the filament from springing off the spool over the flanges and tying itself into a knot. The conical shape of the rollers keeps the spool centered in the holder, and the adjustability of the top roller allows it to accommodate different sized spools (but probably not 3 kg spools).

The spool rotates easily, but not so easily that its inertia keeps it going, and filament won't get tangled.

Video here: https://vimeo.com/219591384

I originally made it without the rubber bands with the intent of simply finger tightening the bolt through the top spool, which worked fine for me, but I took it to the makerspace and found that even after demonstrating how it worked, people couldn't use it properly and started unscrewing the bolt and hanging the spool with the top roller running through the spool hub. Doh! One day I went to the space and found it in pieces, with a washer and one of the bearings from the top roller missing. That's when I added the rubber bands and put a nylock nut on the bolt through the top roller. If you ever want to test to see if something is idiot-proof, just leave it in the hands of some

cosplaypeople at a makerspace for a couple weeks....I printed the base as a single piece, but for 3 kg spools you'd probably have to modify the design a bit and make it in multiple pieces, unless you have a very large printer (like maybe one that uses 3 kg spools).

This is another one I made in which the weight of the spool keeps the rollers pressed against the flanges. It's a bit more complicated and uses many more bearings (this time I used bearings from HDDs), but the base is a little flexible and springy, so maybe not suited to 3 kg spools without a redesign of the base.

Links to the design files for both designs are on the blog page.

-

@puppet172 First thing i would try is mounting the spool horizontally. I have found with the larger 2Kg spools this is enough to sort the problem (in fact once they get going on a bearing they over rotate so to keep the filament taught I ended up using a plastic on plastic mount for some resistance). You see variations of these on the top of delta printers, like this one:

https://www.thingiverse.com/thing:454808Now to answer the actual question, you can define a tool in the firmware with more than one extruder drive, that is useful if you have a mixing hotend and you want to use more than one extruder drive to push filament into the nozzle. but there is no reason you cannot have a tool that has the two extruders in series - so that one is pulling filament off the reel, and another one is just pushing down the nozzle. you can have some slack between the two of them so that they are not too tightly coupled.

-

lol. it's all I could think of...but it should be really easy to fabricate a test model..

-

If it's any help, I took inspiration from @mrehorstdmd and built a 5 spool version using a lot threaded rod and less plastic. The rollers still use bearings and the reels spin really easily. It's modular so a single spool version could easily be made. Each one would take up to 300mm diameter spool with the upper "anti-tangle" roller in place and pretty much any diameter without it. Write up with pictures can be found on my blog here https://somei3deas.wordpress.com/2018/06/11/5-reel-anti-tangle-filament-holder-upgrade/. Happy to share stl files if it helps.

-

@deckingman nice write up. With 5 extruders you are always coming up against stuff that most other people don't have to worry about (like changing the middle spool of 3!)

-

@t3p3tony said in An extruder to turn a spool:

@deckingman nice write up. With 5 extrucers you are always coming up against stuff that most other people don't have to worry about (like changing the middle spool of 3!)

Thanks Tony. And exactly so. For most people changing a reel of filament is relatively quick and painless job. Changing the middle spool of 3 is one thing but when I swap from say a Diamond 3 colour to a Diamond 5 colour, I have to unload 3 spools, then load up 5 spools so it's a bit of major operation. Less painful than it used to be now though.....