How accurate are mechanical endstops

-

I reconfigured my 3 stepper/leadscrew bed to use 3 independent drivers instead of 2 (getting a DueX2 for the one extra driver needed) and added a mechanical endstop on each axis homing the bed like a delta printer. It works well – but one thing I wanted to test was how repeatable the endstops were.

The firmware doesn't seem to offer a way to test this apart from possibly reconfiguring the endstop under test into a temporary zprobe – so I made a simple simple firmware hack to add

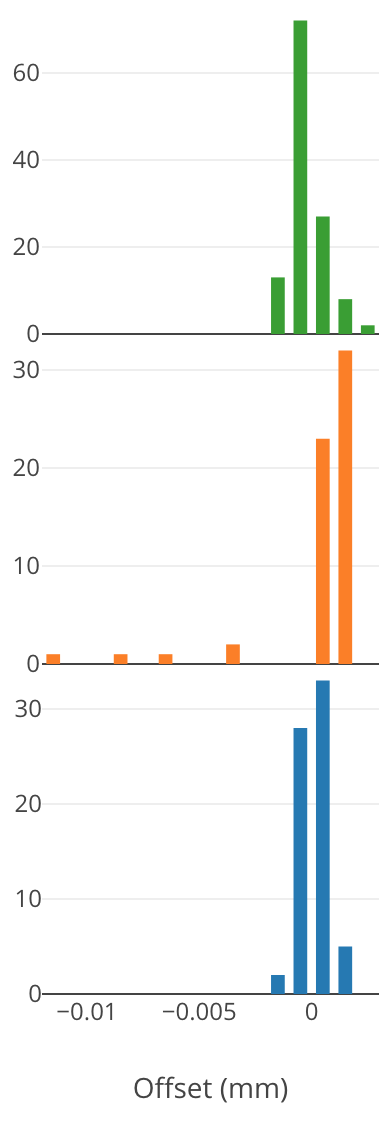

H4option to theG1command to stop – but not re-home the axis on an endstop hit. I could then log the reported Z pos and repeat multiple times for the three different endstops. Plotting the results as histograms:

Some interesting observations. The green and blue endstops seem to be accurate to within ±2 µm (when doing the final homing at 100 mm/min feedrate) which was better than I expected. The orange one had a few outliers –(late triggering) of up to -12 µm – which is probably still not a big deal but higher than necessary. I'll replace this endstop eventually.

One simple way to improve the homing accuracy that I've used in the past on another firmware is to multi-tap the endstop (e.g. 3,5 or 7 times) and pick the median value. The way RRF is designed though I don't see a straightforward way to implement this. Maybe if there was a g-code command to add the current position to a median accumulator register – and another g-code to move to the accumulated median position plus an offset this could all then be implemented as macros. This functionality could also be used for improved bed probing accuracy.

Anyway, just thought I'd share this. Having a way to measure endstop accuracy seems like a nice feature to add (something like the

H4option described above), and a way to improve endstop accuracy by filtering out outliers by picking the median position. -

@RUSS GRIES did a series of tests various endstops for accuracy. Search youtube for the video.

-

On a related note, mechanical endstops are WAY more precise if you take off the metal arm and directly strike the microswitch.

-

@rcarlyle said in How accurate are mechanical endstops:

On a related note, mechanical endstops are WAY more precise if you take off the metal arm and directly strike the microswitch.

So why that metal arm is needed? Always was curious..

-

@briskspirit said in How accurate are mechanical endstops:

@rcarlyle said in How accurate are mechanical endstops:

On a related note, mechanical endstops are WAY more precise if you take off the metal arm and directly strike the microswitch.

So why that metal arm is needed? Always was curious..

Those switches are designed to limit movement in NON PRECISE mechanisms, like coffee makers, or door openers, or a million other things. The arm, or an arm w/roller, makes it much more RELIABLE to 'hit', despite alignment of parts being accomplished via slots in stamped sheet metal, etc.

We are taking advantage of a mass produced item's low cost, and attempting to re-purpose it for PRECISION, and we can do other things to help ensure reliable hit in our very rigid, and hand assembled, hand aligned, machines.

Removing the arm makes it harder to "hit", and much more precise when it is hit.

-

@danal Got it, thanks! Will write down my next mod to the list )))

-

@rcarlyle said in How accurate are mechanical endstops:

On a related note, mechanical endstops are WAY more precise if you take off the metal arm and directly strike the microswitch.

Yes, there is a significant (2~5x) lever arm effect. Incidentally, the orange endstop above lacked a lever while the two others have them on. You can see that the inlier distribution seems tighter on that one.

@timcurtis67 said in How accurate are mechanical endstops:

@RUSS GRIES did a series of tests various endstops for accuracy. Search youtube for the video.

Cool. I watched the plots in that video and the accuracy numbers seem to agree with what I got pretty well. Nice to see that microswitches actually live up to their name.

@danal said in How accurate are mechanical endstops:

Those switches are designed to limit movement in NON PRECISE mechanisms, like coffee makers, or door openers, or a million other things. The arm, or an arm w/roller, makes it much more RELIABLE to 'hit', despite alignment of parts being accomplished via slots in stamped sheet metal, etc.

They also significantly reduce the force required for triggering which is important in many applications.

-

In my unscientific experiments using mechanical endstops and the baby stepping (0.05mm) feature of the firmware, I have found that the repeatability seems to be the same lever or no lever arm, but without a lever arm the amount of movement between actuation and deactuation is reduced significantly.

Number of steps to (de)actuate:

With lever: 10-11 0.05mm baby steps

W / o lever: 2-3 0.05mm baby stepsOf course going no lever with virtually 100% striking chance is much more difficult. I always use XY with a lever and Z without.

-

@digitalvision said in How accurate are mechanical endstops:

They also significantly reduce the force required for triggering which is important in many applications.

Good point. They trade more travel for less force. Which we don't need.

-

@danal said in How accurate are mechanical endstops:

Removing the arm makes it harder to "hit", and much more precise when it is hit.

What that means? In case of 3D printers. I know exactly where switch is and I can precisely hit it, no? Or not to "over" hit? )

-

@briskspirit said in How accurate are mechanical endstops:

@danal said in How accurate are mechanical endstops:

Removing the arm makes it harder to "hit", and much more precise when it is hit.

What that means? In case of 3D printers. I know exactly where switch is and I can precisely hit it, no? Or not to "over" hit? )

You've got it exactly right.

Taking off the arm, on a 3D printer, has almost no downside because we can align to the switch. It has upside because it makes the switch more precise.

-

@danal Thanks for explaining!

Now I don't understand why most 3D printers come with lever arm... but will try to remove mine on Z axis and later on X/Y

Now I don't understand why most 3D printers come with lever arm... but will try to remove mine on Z axis and later on X/Y -

Just thought I'd chime in here as the title is " how accurate are mechanical endstops" but the thread seems to be about lever arm micro switches which are just one type of mechanical end stop.

I use a precision positioning switch for my Z axis. It's made by a Japanese company called Metrol which seems to be at the forefront of these things. Claimed repeatability is 0.005mm and after over a year of use, I have no grounds to dispute that claim. Since installing it, I have never had a need for baby stepping and never had any problem with the first layer. I did a bit of a write up on my blog here https://somei3deas.wordpress.com/2017/03/21/setting-up-a-metrol-positioning-switch/. There are links to the various web sites in the blog post.

The beauty of it is that it's just a simple switch so nothing fancy required to interface it. I chose the version with a built in LED so I had a visual indication of when it triggers which means that it needs to be treated as an analogue probe due to the series LED but the non LED version can be treated as a simple switch.

Oh, and if 0.005mm repeatability is still too course, they do a 1 micron version and I believe now there is also a 0.5 micron repeatability version too.

-

@deckingman Wow, they are pricey...

-

@briskspirit said in How accurate are mechanical endstops:

@deckingman Wow, they are pricey...

Ahhh, well I didn't say they were cheap. TBH I can't remember how much I paid but it wasn't extortionate. Probably a bit more than say a BL touch but about a thousand times more reliable and easier to set up. The price will depend on the configuration you choose and where you can source one locally. You wouldn't want to use one for homing X or Y because positional accuracy in those cases isn't too important. But for homing Z, this is exactly the type of application that these switches are designed for.

-

Here you go - this is the Misumi UK site where I bought mine https://uk.misumi-ec.com/vona2/mech/M0400000000/M0402000000/M0402030000/M0402030100/

Part way down, "Contact Switches/Standard". Listed as a Misumi part but it comes with a sleeve on which is emblazoned the word "Metrol" (because that's who really make it). Price is 32 Euros which I don't consider to be extortionate for a highly reliable, highly repeatable, easily configured Z probe.

-

@deckingman I've found them on Amazon US for $48, a bit later will buy for Z