Stop Thermal Transfer from Bed to Frame

-

I've been happy with stainless spacers and fasteners. Stainless steel has roughly 1/4th of the thermal conductivity of aluminum.

You can get ceramic spacers but their length tolerance is very loose and I was worried that they would bend the bed out of shape. If you are willing to lap ceramic spacers to the same length it could be an improvement. I would probably always use stainless fasteners, but nylon plus ceramic might be rigid enough.

I also purchased an insulated heater from Keenovo and shaped the bed to reduce heat transfer:

-

My plate is mounted using these:

No issues with excessive heat transfer to the frame.

-

@richardmckenna Well you can use the nylon and settle for sub par prints, or just suck up the extra energy cost and go with the aluminum spacers. How hot does the frame get?

-

For each mount point, you could mount a block of ptfe (teflon) to your extrusion using one scres, and then in an offset hole, with a different screw, mount the bed to it. That would thermally insulate the frame from the bed.

-

@surgikill I don’t think they are my only two options given some of the suggestions from other people here. I don’t quite understand why you are being so negative about me wanting to improve the performance of my bed and stopping heat where it shouldn’t be.

After an hour or so it is pretty much the same temperature as the bed.

I think I’m gonna try the stainless steel suggestion a fraction of the thermal conductivity and hopefully nice and accurate.

-

@blt3dp I like that idea I remember seeing some thick sheets of PFTE on eBay months ago. I will have a look. Thanks.

-

Just asking ... why is the idea of printed parts so bad in terms of accuracy?

-

@richardmckenna You're still going to get transfer if you are using metal screws. Seeing as the bed is aluminum, you might want to put a piece of steel or a magnet on the top side of the bed. Then you can use a magnet pressed into a printed piece underneath the bed and there will be 0 metal pieces connecting the bed to the frame. Personally I wouldn't worry about it unless it is negatively affecting your printer. Just make sure there is some airflow over your electronics and it will be fine.

-

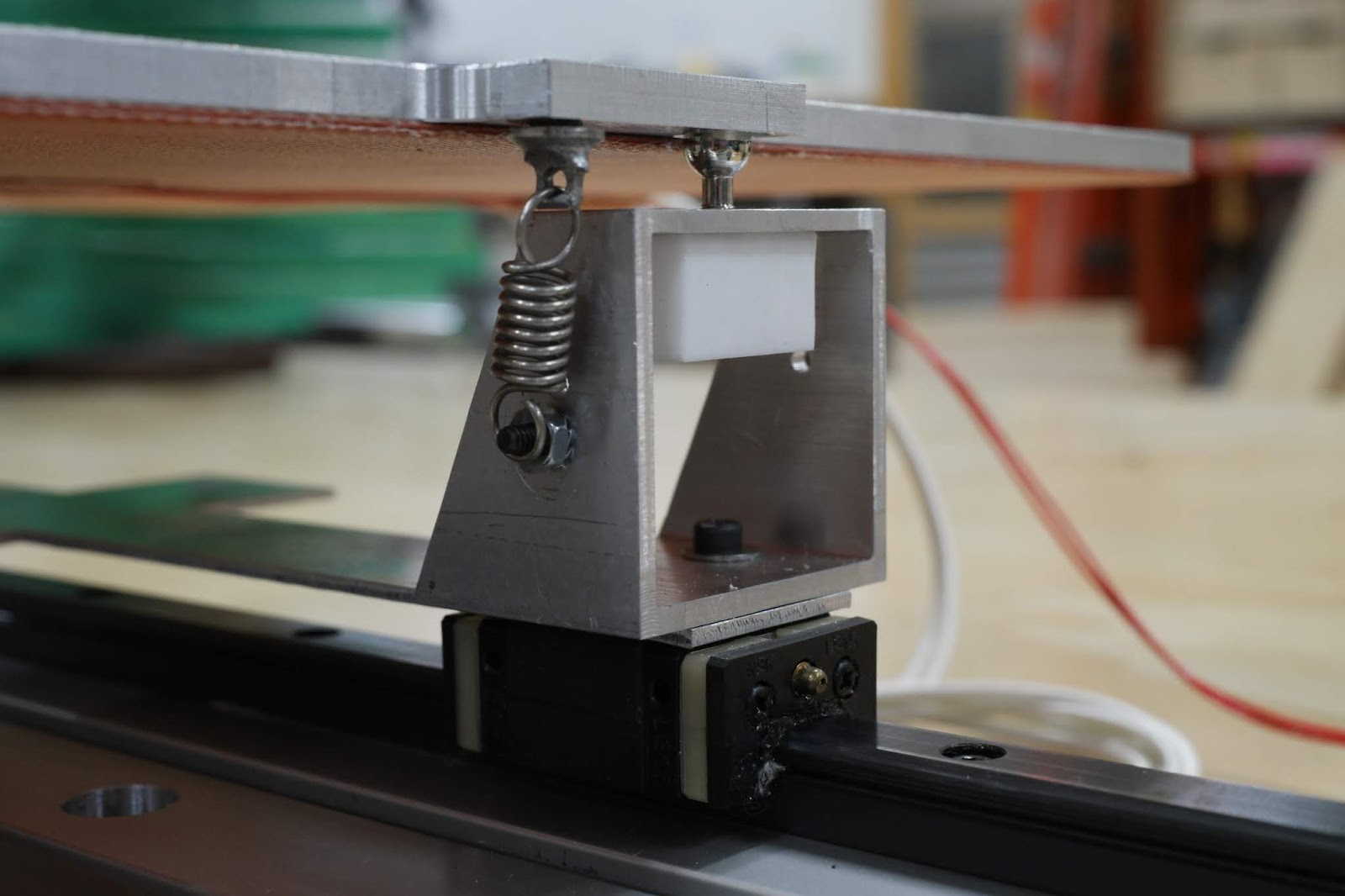

I use teflon blocks with slightly undersized holes for the leveling screws. The holes grip the screws tightly and prevent them from wobbling, and the teflon plus steel screws minimizes heat transfer, and teflon doesn't mind the heat at all.

Here's one of the leveling screws on a bed-flinger printer (SoM) I recently converted to a kinematic bed mount.

I don't insulate the underside of the bed because I close the printer to print ABS. Any heat "lost" from the underside of the bed warms the enclosure. Electronics are mounted below and outside of the enclosure.

-

@richardmckenna

I have had the same issue my printer is 300mm x 600mm also with an aluminum bed. I had exactly the same issue of heat transfer to the aluminum profile extrusion frame. I found some round garolite rod about 25mm long 15mm diameter. (you can get various sizes from McMaster Carr althought there are other suppliers that are cheaper. I drilled the rod and inserted Heli Coils in both ends. For the end that goes to the profile aluminum I used the profile nut with a set screw of the proper size. I threaded the Garolite rod onto the set screw and tightened the just bolted the cast aluminum plate to the other end of the garolite. There is absolutely no heat transfer. Make sure that the set screw and bolt do not touch as this will defeat the purpose. -

Here is an image of the setup that I used for the garolite

https://1drv.ms/u/s!ArsUUgUVyLkdhq02CHFbp6Ctv00auw -

As you guys know, I only got my grade 10 but my thinking thoughts are saying that if the heat transfers to the frame then could it be possible for the frame to experience thermal expansion on some level or another and then obviously it could be for to say that the frame might flex or mess with the calibration?

-

@ricky_grade10 exactly. and hopefully by using one of the methods others have described above I'll be able to stop it as much as possible.

-

@richardmckenna yes indeed and just to further my suggestion I used a 25mmm hole drill to cut some discs out of 10mm thick PTFE Sheet works like a dream.

Doug

-

@dougal1957 Thanks Doug. I found some 10mm and 20mm thick PTFE offcuts as well as some stainless steel spacers on ebay. So I'll give them a go when they arrive.

I was just going to cut blocks out of the PTFE but I do like the idea of them being round.

-

@richardmckenna I had a holes in the tool box which is why I used it drilled the hole in the middle (it is a little big but it allows some wiggle room to move the disc so it doesn't overhang the extrusions)

and cut the round at the same time easy lol -

you can find ceramic spacers at mouser

https://www.mouser.de/Electromechanical/Hardware/Standoffs-Spacers/_/N-aictf?P=1z0z0py -

@richardmckenna Assuming a temperature delta of 40 degrees and a length of extrusion 500mm in length you aren't even looking at 1mm of expansion. As far as accuracy of the frame goes that is going to matter. However, if you keep the bed bolted down and the frame does not expand with the bed you can end up with issues like the bed buckling. Unless you are noticeable seeing defects in your print because of it just let it be.

-

@richardmckenna Still can't remember the name of the stuff I used but do a google search for under "floor heating insulation" or some such. I did find a picture though

So it's two layers of thermal insulation, then the 10mm thick aluminium plate, then 6mm of glass on top. Counter sunk bolts go through the aluminium and insulation and screw into T nuts in the frame. Thermal transfer to the frame only happens through the bolts (which are stainless steel) so it's negligible.

Nice and simple. It may not be any good to you though, depending on your bed levelling arrangement. I have 3 screws and a single belt and simply slacken the grub screws holding the pulleys onto the screws, adjust each screw and tighten the grub screws up. I've only had to do that about 3 times - each one after disassembling the machine to move it.

-

Just a thought, but I wonder if rubber vibration insulators (basically a piece of hard rubber with 2 bolts moulded in top and bottom) would work? There are small ones holding a plastic cover to the top of the engine in my car. They can take lots of heat and are moulded so they should be exactly the same size. Something like this:

https://www.ebay.co.uk/itm/Aeromotive-Fuel-Pump-Vibration-Dampener-Mounting-Kit-11601/362096382511?epid=1168728755&hash=item544ea0522f:g:zkIAAOSwWaRZsnyp:rk:3:pf:0

but cheaper!