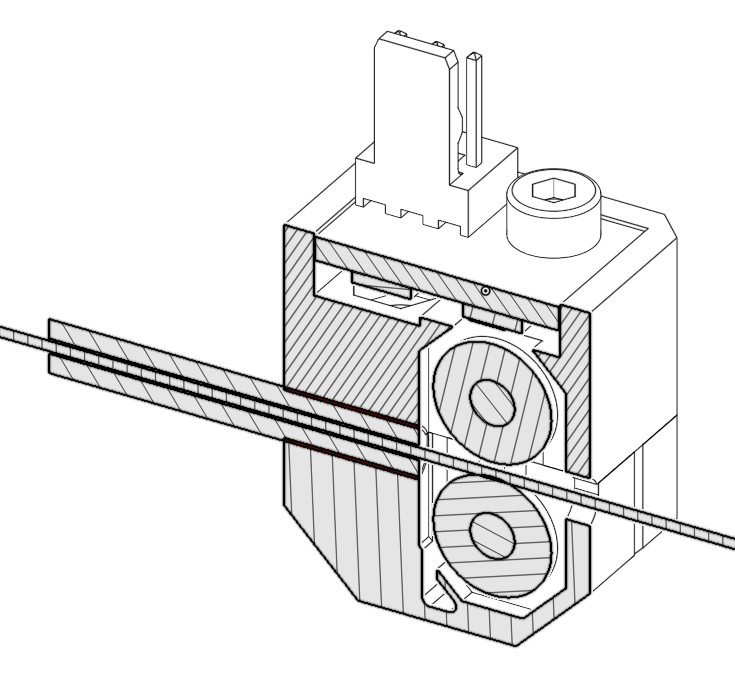

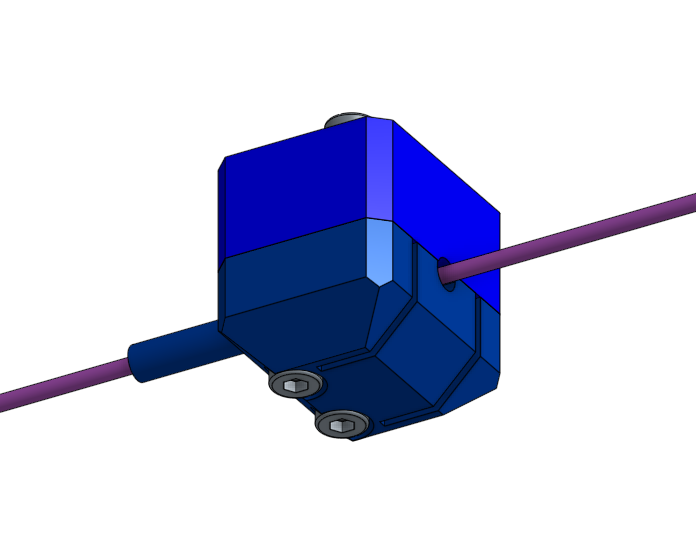

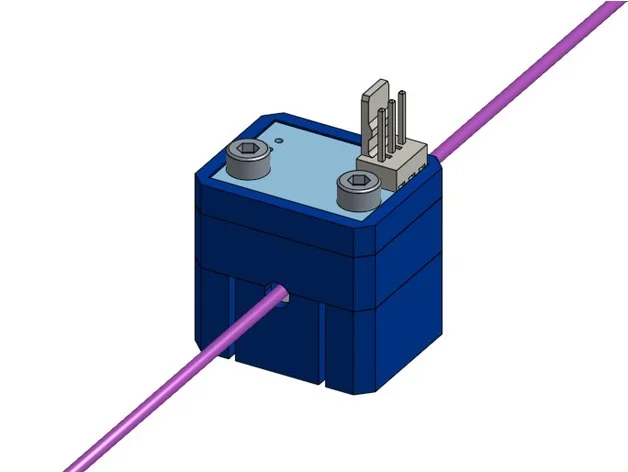

Indirect (bearing) laser filament monitor concept

-

I designed a new casing for the Duet3D Laser Filament Monitor to hold two bearings with a compliant mechanism spring to try indirect reading of filament extrusion. The sensor will read the bearing surface instead of the filament and I hope this should end the issues with different filament colors and types.

I'll test print it today and if it works I'll publish the files as soon as possible.

-

It looks really good. I'll be following this one.

I've been running the filament housing turned at a 10 degree angle with mixed results so far.

-

Same here as tim, bought my filament monitor time back but still hadn't decided how to mount it, this looks good.

-

Finish printing... And realized that I lost my small bearings.....

I stored at some safe place to not lose it and now I do not remember where

-

I'll release the current design for those who have a 693ZZ bearing at hand and want to test and redesign it for the F623ZZ bearings that I have spares.

-

@brunofporto said in Indirect (bearing) laser filament monitor concept:

Finish printing... And realized that I lost my small bearings.....

I stored at some safe place to not lose it and now I do not remember where

What the heck are you doing in my house??!??

This is great thinking outside the box (well, maybe INSIDE the box).

LOVE THIS!

Don't have that sensor, but if this works it gives me a reason to have one. Well done.

-

If you have the Duet3D LAser Filament Monitor and a pair of 693ZZ bearings here is the prototype.

https://www.thingiverse.com/thing:3558691

I'll redesign it for the F623ZZ

-

@puterpro Pretty sure I'll find them when they are not needed anymore

-

Have done a test print of the 693zz version in pla.

As you can see, the jaw tends to drop somewhat when the filament goes through. Do you think it needs some extra support? - maybe a plate that goes on the bottom? Or perhaps it would be better in petg? For my printing, I think the 4mm slots for the bearings could do with a tiny bit more tolerance. Great idea though - I am about to order a laser monitor on the strength of it. -

this looks very good

do you have any tests to show the difference?

might put this on my printer if its actually working good

might put this on my printer if its actually working good

-

@adrian52 It was supposed to work like that!

The spring is integrated.

The spring is integrated.Does it deform permanently or it comes back nicely to the original position? When you pull the filament can you see the bearings moving?

-

@johnjohn1990 Still not tested... I lost my bearings and now I am designing for the F623ZZ that I have here.

-

I wonder... how much work would it be to give this a go with the 608ZZ?

-

@brunofporto the bearing moves ok, but it feels like the jaw is having to move too far, overstretching a little past the point where it would spring back strongly.

-

@adrian52 Thanks!

-

@brunofporto realised later that one of the bearings was not fully seated, so your bearing gap may well be right. Still need a bit of tolerance for the outer part of the bearing, and I suspect that the jaw spring may need to be a bit thicker. Will try again - thanks for the design.

-

Those changes seem to work OK

I used 0.1mm gap on each side of the bearings, and added 1mm to the base of the jaw to make the spring stronger. I didn't have room for washers, but the bearings rotate quite freely. -

@brunofporto How is the sensor working out for everyone after this modification?

-

Thank you for sharing with us.

I have a magnetic sensor from about 1 year and it works flawlessly.

I don't know if laser costs less of magnetic, but the need of a bearing system in the laser sensor affect the simplicity of this device reducing or annulling the advantages over the magnetic one.

IMHO

.

good idea anyway -

I haven't really tested it yet after the initial test runs.

In my case, the range was always between 1% and 25%. So not really usable. I have loads of the 693ZZ now, so can experiment. I'll try to paint it over with a sharpie and see what that will do.

Another thing is that I had to enlarge the cutout for the bearing. My bearing is exactly 4mm and the gap is the same. There's no way washers will fit in there along with the bearing.