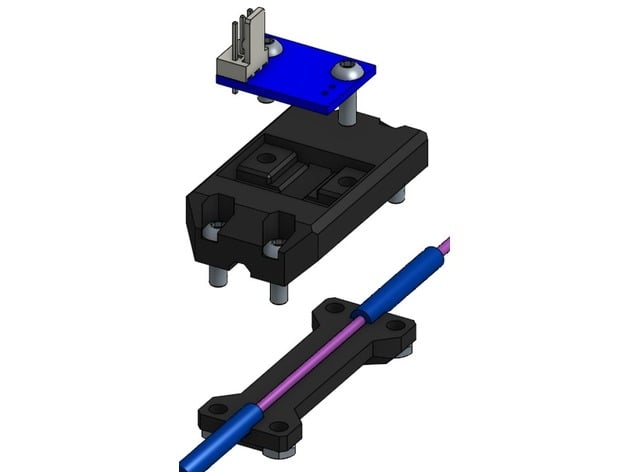

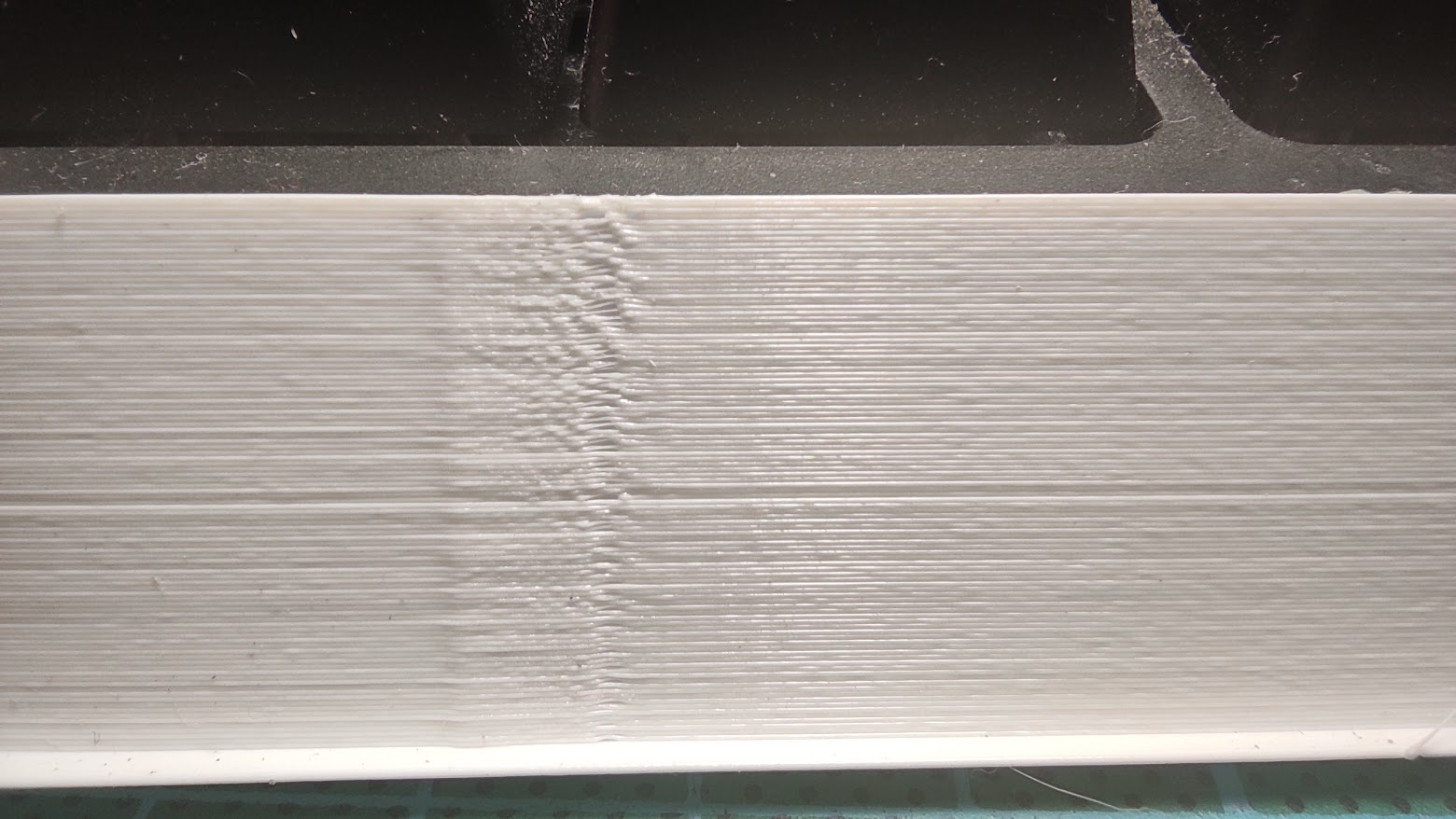

I am having several issues with PA too.... The test using the python script have bulges AND under extrusion even on very high values of PA.

Here an example for PLA from 0.5 to 0.9 - The bulge NEVER disappear even when the under extrusion after starts to show.

In the past there always a clear transition where the slow segments had the same width and no under extrusion after.

Also I simply cannot find a value of PA + Retract that lead to good results. It starts to to cause excessive retraction and blocking issues much before solving any oozing.

I reviewed all my hardware looking for possible issues and after finding this thread I think it is related.

It is very severe with small details and curved surfaces (like round small posts for retraction tuning) it is so severe that sometimes and entire layer is mission while others spurts excessive material. For straight lines - like a small cube walls - only the bulge is apparent and the under extrusion after the bulge for higher PA.

I had not updated my board for a long time and the issues started after the update to 3.4 - I do not remember what older version I had before.

But the issues are the same: Excess extrusion even with very high PA with under extrusion right after for higher PA. I had not of these issues before.

I will test 3.4.2 now and then roll back to 3.3 and repeat the Python script test to compare.