Super Volcano with BMG and 0.9 Motor Wierd behaviour

-

Hello Mindhive and thank you in advance for your input.

I have build a CoreXY on which i use Zaribo motors 1.8 for XYZ and 0.9pankake for E with BMG extruder and an E3D supervolcano.

At the moment i am trying on Prusa Slicer to build a profile and it seem i have found my self with a curious issue.

I have Calibrated E steps and multiplier and i get precise thickness over 2 outer walls, but when it comes to my infill, its always much thinner than what i have setup.

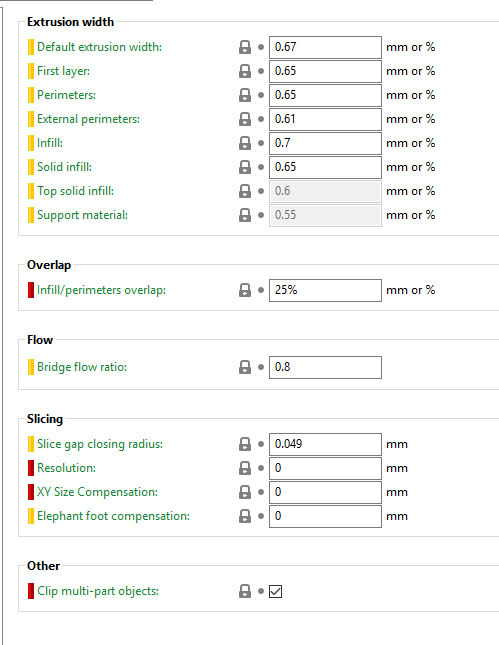

My configuration is as follows and i have attached pictures of slicer settings.

M350 X32 Y32 Z16 E8 I1 ; Configure microstepping with interpolation

M92 X160.00 Y160.00 Z400.00 E407.00 ; Set steps per mm

M566 X800.00 Y800.00 Z100.00 E3000.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z400.00 E6000.00 ; Set maximum speeds (mm/min)

M204 P6000 T6000 ; Set printing and travel accelerations

M201 X5000.00 Y5000.00 Z60.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X850.00 Y850.00 Z950.00 E950.00 I35 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30

-

rectilinear infill? try grid instead

-

Are you using Maestro board? If not M350 line is not OK, but its not the problem here.

Try to set Max volumetric speed in slicer to 20 (it's under Filament settings-Advanced or under Print settings-Speed) and see if it is any better. -

I am using the wifi board and for some reasson with M350 E8, i found better results than 16 microsteps.

I will check the volumetric config on slicer. Thank you. -

If the infill is rectilinear, it is bridging. 0.8 bridge flow ratio x 0.7 line width = 0.56 mm, not too far from what you're measuring. When bridging the line won't get squashed flat, so it will probably measure narrower than the calculated value, which means it's probably about right.

-

Had never though that rectalinear might be considered bridging. Makes sense and i will test more infill patterns to compare. Thank you

-

Apologize for reviving such an old post but would be really interested to hear where you ended up and if you wouldn't mind sharing your Prusaslicer profile!

-

@singhm29 No problem sharing my current profile for my Ratrig CoreXY. Would you like PLA or PETG? Remember that this is for a SuperVolcano

-

I see no linear or non-linear extrusion correction. Was that checked?

-

@TonyGR PLA please! Yep tackling the supervolcano as well. What nozzle size did you end up sticking with?

-

@TonyGR don't forget about me