Non planar layers

-

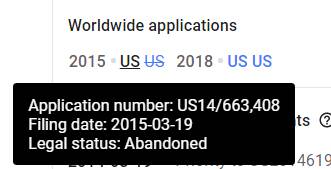

I am not a lawyer, but I looked into the patend and saw it was abandoned in 2015, and there is an article https://smallbusiness.chron.com/patents-abandoned-65186.html explaining when a patent was abandoned, it can be used. A commecial produced product between abondent and new status active needs not to pay fees.

But as I said, I have little patent knowledge.

But as I said, I have little patent knowledge. -

@joergs5

good info but strange that the patent was only applied for in 2015 by auto desk.further investigation is required I think.

-

But AFAIK, a patent only prevents commercial use of something; I don't think it forbids someone to develop free sofware for personal use...

But I don't know if it is a problem for a university. It could also be a problem if Prusa Research implements something patented in their Slic3r fork...

-

This post is deleted! -

I don't know the status of the Autodesk patent, but there is at least some prior art in 3D printing:

Some other prior art to the March 2015 Autodesk patent, specifically 3D printing:

April 2013 - https://www.thingiverse.com/thing:75735

July 2016 - Hackaday article https://hackaday.com/2016/07/27/3d-printering-non-planar-layer-fdm/

Nov 2014 - Comment in Hackaday article https://hackaday.com/2016/07/27/3d-printering-non-planar-layer-fdm/#comment-3105340 leads to https://github.com/nick-parker/Bread first commit in github was Nov 2014.Ian

-

Note that 2 of these links are not the same technic: they just distort a part, and can't slice a non planar part...

I plan to give a try to Bread.

-

An additional option and innovation to non planar printing: a nozzle which can rotate in all three axes so that the edges of the nozzle do not disturb the non-planar printing and the nozzle can be closer to the layer. Nozzle direction and hereby filament flowout of the nozzle is freely controllable.

-

@joergs5 Nozzle only needs to tilt in two axes (doesn't need to rotate), and it can be the bed that tilts, rather than the nozzle. Moving the nozzle in more than 3 axes (though think milling bit) is common in CNC milling machines, and more recently water jet and laser cutting.

Ian

-

@droftarts well, yes, I thought of the possibility of concrete printing where the direction of the nozzle is important (and a nozzle where a Kevlar wire precedes the print). And I thought of printing walls and later the infill with a flexible nozzle also.

-

@joergs5 said in Non planar layers:

Before someone protects it by a patent, an additional option and innovation to non planar printing:

The nozzle can be swivelled in all three axes so that the edges of the nozzle do not disturb the printing during non-planar printing and the nozzle can be closer to the layer. The controller controls the tilt of the nozzle. Nozzle direction and hereby filament flowout of the nozzle is freely controllable.

Don´t get on the high horse, this type of 5 axis printing is already patented.

By the way, you cannot patent a possibility or "can be", you can only patent the execution of that idea. More simply. it´s not WHAT is done, it´s HOW it´s done that´s patentable.

Simple example: you cannot patent the process of boiling water, but you can patent HOW the water is boiled, for example you invented a water boiler that does this by using fusion energy. you would have to describe in detail how the fusion energy ends up in the water, and THEN you can patent it. -

@nitrofreak Thank you for explaining the patent process and the existing patent. The patent is not applicable, it is a process for preheating. But your information about what is patentable was useful, thank you.

-

Another old 5 axis 3D-printing complex shapes: https://www.youtube.com/watch?v=iaZeTlios0w

-

This post is deleted! -

I had some thoughts about nonplanar printing and found this thread. I would be interested in knowing which of these ideas are already common notions. Thanks!

Lots of people are talking about nonplanar extrusion. Taking this to extremes, make an extruder nozzle that is long and thin. Have several angled in different directions or one whose angle of attack is steerable. Then have a slicer that follows contours of the model: Attempt to make a layer match the normal to the thinnest material laid down so far. Intuitively, if you are making a U, you build up the inside strip by strip. Lots of caveats: Have to account for extruder interference/dexterity, have to build up the uprights of the U over time.

Related to above: Make the fill path of each layer more variable. Do a back-and-forth along X and then the next layer along Y. Or three orientations. Or again, don't make the layer planner in the short dimension either. Make it a hump. So a re-anglable tip runs over it on an arced path. Again, using different infill orientations on each layer.

Stop thinking of layers as planar and think of them as external. You have a current lump of material and you are adding more to the outside. You are looking for the optimal grow shape, both for efficiency and stress. So it is a hump in two dimensions that you build up.

Basic idea is to not provide flat or consistent surfaces of weakness to an type of stress. Think of what extrusion would make a structure most durable, then design an algorithm that will approximate that path. For the standing thin shapes, you have a trade-off between vertical building and standing up against gravity. I would say that you are building up hills with the path running up and down around the outside. The rate at which you gain height is based on what the material can support. The more the material will support, the longer the threads that can be laid down along the center area and so the more resistant to tension. In general, you want stress to pull along extrusion threads, not separate layers of them.

Perhaps the ideal solution would be a constraint minimization of breaking off the extrusion as little as possible and altering the direction of path as little as possible. Ie, long continuous threads.

- Minimize layers by following model contours.

- Squiggly infills vs. dashes in one direction.

- Infills that follow long axis.

- Less planar layers = more deposition per layer.

Finally, to solve the detail problem, note that a sculpture has two parts: the structure and the surface. The structure is there to put the surface in the right place. It has no personality, it just wants to resist deformation. The surface does have some structural properties but they are different. It wants to hold its detail and resist abration. Abration isn't anything like torsion. Nor is holding small scale features.

So following with the idea that you are building up the outside of a model, make the structure and then paint on the detail. This also allows for varying color, texture, softness, sheen, etc. Areas of variability are useful both for artistic pieces and machine parts.

Ideally, detail should not even be done with the same head(s). Different temperature, extrusion rate, material, arm dexterity. The detail head would be much slower but have much more articulation. Maybe even rotate the model? Or maybe you only use as much floor as you need to support the model to allow attack from below. Ie, the slicer tells you to put a stand of a certain size on the build area before you start.

There is much less detail work to be done than structure so it is reasonable to use a slower, more precise instrument.