Pressure Advance seems to not be working.

-

@zapta Its bowden, around 650mm bowden length.

-

@Samuel235 said in Pressure Advance seems to not be working.:

Hiccups: 129

I wouldn't be too concerned by this over the course of a print.

Do you happen to have Z hop on retract enabled?

You can do more fine grained testing to try and pin down when the hiccups are occuring. Every time you send M122 it resets the counter, so you can send it at the start, send it after homing, send it after the first layer, etc. and eventually you'll get an idea of where and when they are occuring.

-

@Phaedrux - I was doing this while it was printing also, it seems to be consistent on most layers if i remember correctly. I'm not currently running Z Hop, no.

-

@Samuel235 said in Pressure Advance seems to not be working.:

@zapta Its bowden, around 650mm bowden length.

0.22 for a 650mm bowden is very low, good for you. I got > 1.0 with 600mm 1.9mm capricon bowden and lowered it to 0.15 when switched to direct drive.

-

I'm currently running some tests to attempt to calibrate it. I'm currently using CURA so I'm unable to force a seam to be in the middle of a flat face, so i'm using a cone print to put a seam on the face and to change PA as the print goes and then to find the best section. I'd be interested to know the calibration method you all face, do you all go for the python script that is floating around?

-

@Samuel235 said in Pressure Advance seems to not be working.:

I'm currently using CURA so I'm unable to force a seam to be in the middle of a flat face

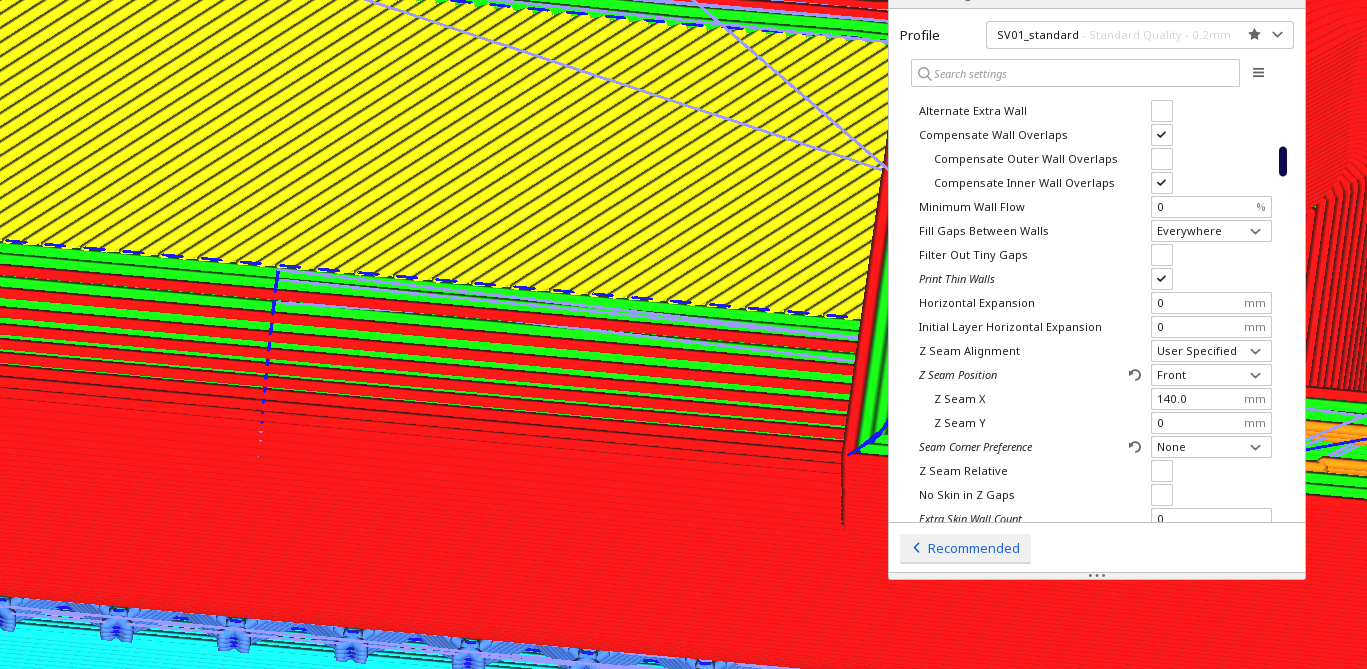

It can be done in Cura.

https://ultimaker.com/en/resources/52343-shellThe options may be hidden by default. Use the gear icon on the shell heading to see any hidden options.

Z seam alignment - User specified

Z seam position - back

Seam corner preference - noneProduces the desired result. That's in 4.4.1. In older versions there was an X and Y position you could specify. The setting is still there in the settings visibility filter, but it's not being shown and I'm not sure what's blocking it. Regardless, setting it to back, front, left, or right works to align it to a face.

-

@Phaedrux - Im on 4.2.1 and the XY position will not put it in the middle of a flat face for me and a few others I chat to. I will try their update shortly to see if that new option works for me.

-

@Samuel235 The corner preference must be none as well.

-

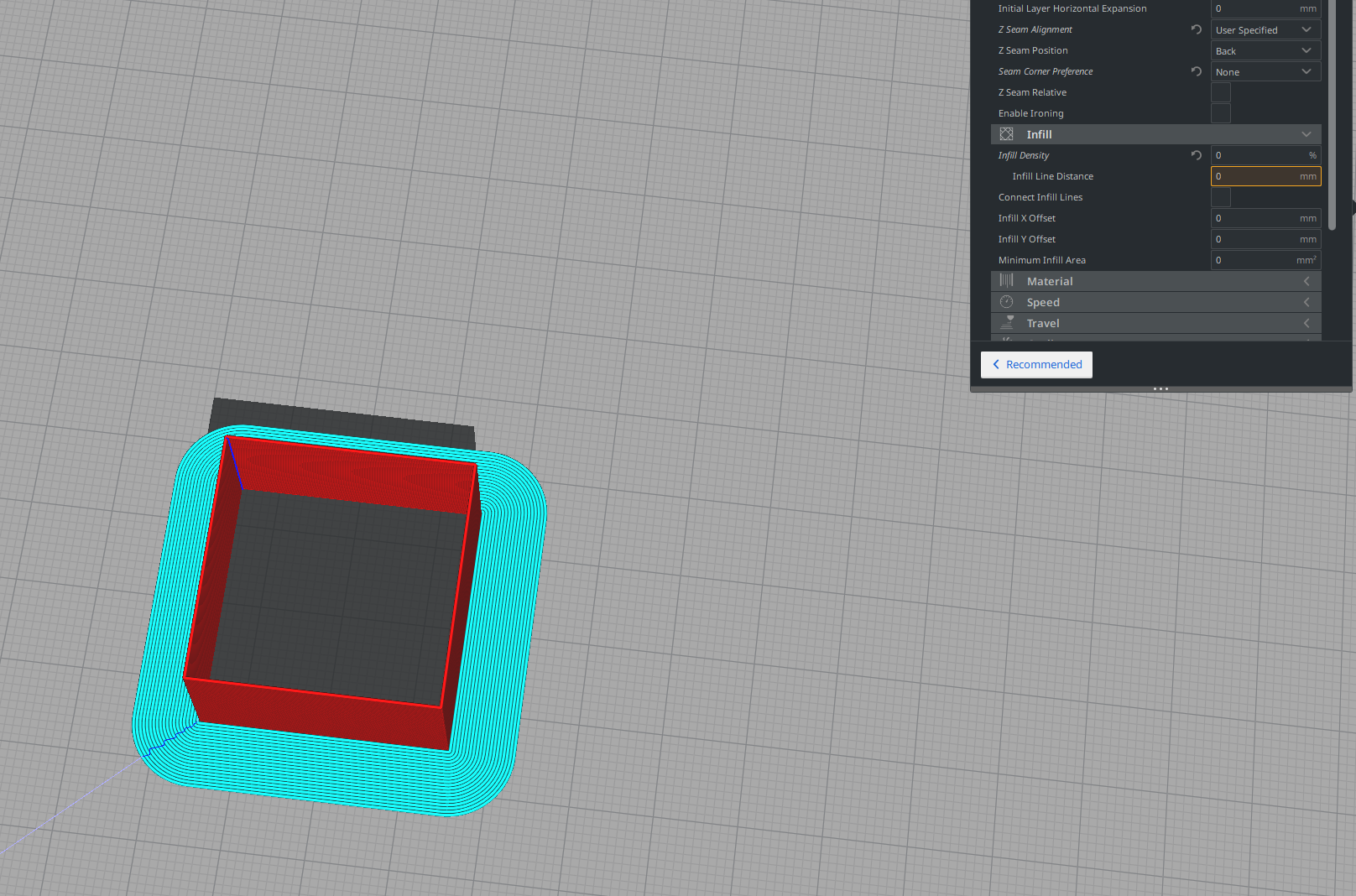

I have just updated my Cura, and still facing the same issues:

Will attempt to find a work around later today using another slicer.

-

Re getting the z-seam in the middle of a flat face using Cura. Well, it can't be done using the UM releases but my Cura builds do now provide that capability. Setting the z-seam to user-defined and seam corner preference to none will enable this feature. You can find my releases at https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0. Please read the README.md file there for more info.

Here's an example, you can see the travel moves associated with the z-seam to the left of the middle of the flat area at the botttom of the image.

-

@burtoogle said in Pressure Advance seems to not be working.:

Well, it can't be done using the UM releases but my Cura builds do now provide that capability.

Just one more reason to use your builds.

@Samuel235 I was going by memory on the settings and didn't realize that the stock Cura does not allow this.

-

@Samuel235 For what it's worth, setting the seam to a corner of the cube is also usable, it just makes finding the smoothest transition a little harder. You can also use a cylinder, but then you miss out on the corner bulge tuning.

-

Oh awesome, thank you for including your build @burtoogle!

@Phaedrux - I have been using a cone, I imagine this to be the same as a cylinder for the sake of this test, just the layers would get quicker as they go up, and I ranged from 0.1 to 0.9 PA, I didn't get any change in apperance of the seam at all across the range of PA values unfortunately. I will try with a cube tomorrow to test.

-

A cone might be ok. I think the fact the size is changing as it goes up would make it harder to see the difference in the seam since the layer time is a confounding factor.

The cube is probably the best option for this because you get up to speed over the 100mm length and the corners show the bulge and the seam on the face is clearly visible.

-

Currently printing a 100mm cube with a single skin, no infil. Seam is in the middle of the face at the back with the build of Cura linked above (Thanks @burtoogle). I have PA changing its value from 0.05 to 0.9 in 0.05 increments every 25 layers. Will see how this turns out.

-

Cube just completed:

As you can see throughout the range of 0.5 to 7 PA value there is no difference. This was with a jerk value of 8000mm/min. I’m dropping that jerk down to 4000mm/min now for another test. Should i expect to see any improvements with lowering the extruder acceleration value too?

-

@Samuel235 something isn't right. There should definitely be some noticeable difference over such a wide range of 0.5 to 7.

What command are you using?

Can you post your config?

-

Nothing has changed from the settings i posted originally, other than change to the extruder current limit. Do you want me to post them again (Asking as i’m not at my system at the moment but will get to it if needed) so you can confirm any typos were not made or something? I don’t believe there is anything i would have typoed as It was just a change of number not a command or anything.

-

How are you changing the PA value? Via the console during the print, or is it scripted into the gcode file?

I'm thinking it may not actually be getting applied because there should definitely be some visible result. At a value of 7 you'd likely see the extruder reversing dramatically.

-

@Phaedrux - its hardcoded into the code, but i confirm it changes every 25 layers using the command line console. The extruder behaviour changes each time PA changes, i can confirm that. But nothing changes in the print.

Im thinking PA is working but something is masking its effects, hence why i was thinking of changing jerk and possibly acceleration on the extruder.