Duet 2.05 memory leak?

-

@Phaedrux no other slice supports different diameter nozzles for different extruders. I tried setting up in cura recently and that wasn't an option. My startup script uses s3d specific variables for temperature setting. Other slicers are better than s3d on many respects, but s3d is still better at multi extruder setup -- since it can all be done via multiple processes -- so it's still not an option for me.

-

@Phaedrux -- yep, running fine now with a fresh copy. Underruns are not piling up doing fine -- I can check S3D option for decreasing small movements -- not sure if that has anything with what's going on.

-

I suspected as much. S3D can create some odd gcode with lots of small segments sometimes which may be half the problem.

I wasn't aware of the nozzle size limitation in Cura. I was pretty sure it was an option the last time I had multiple extruders setup for the Palette 2.

-

@Phaedrux Palette 2 uses 1 nozzle -- I have palette+. It's effectively a mixing hotend, same prusa slicer -- it's geared for the MMU -- which is still a single nozzle. So there is no reason to specify different sizes for extruders. This has been a limitation since I first tried to use multi extrusion on my maker gear i had a 0.35 nozzle and 0.5 -- and I could only set it up in S3D. There is only a python script that I could that would slim down S3D gcode to avoid unnecessary moves. However -- why is it printing fine and happy now underrun free -- nearly an hour in -- I know this print will succeed. The pain point is 30 minutes in. What's odd to me is the cura is developed by ultimaker and they have the UM3 with their different print cores, and I would think having the ability to use the 2 print cores for different resolution would be something they'd want to be able to do, but I guess they expect you to match print core nozzle diameters.

-

@kazolar said in Duet 2.05 memory leak?:

@Phaedrux Palette 2 uses 1 nozzle -- I have palette+. It's effectively a mixing hotend, same prusa slicer -- it's geared for the MMU -- which is still a single nozzle. So there is no reason to specify different sizes for extruders. This has been a limitation since I first tried to use multi extrusion on my maker gear i had a 0.35 nozzle and 0.5 -- and I could only set it up in S3D. There is only a python script that I could that would slim down S3D gcode to avoid unnecessary moves. However -- why is it printing fine and happy now underrun free -- nearly an hour in -- I know this print will succeed. The pain point is 30 minutes in. What's odd to me is the cura is developed by ultimaker and they have the UM3 with their different print cores, and I would think having the ability to use the 2 print cores for different resolution would be something they'd want to be able to do, but I guess they expect you to match print core nozzle diameters.

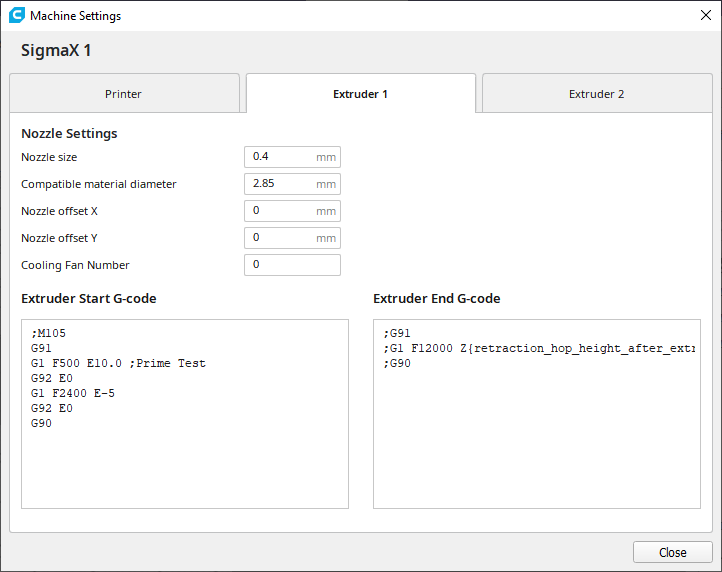

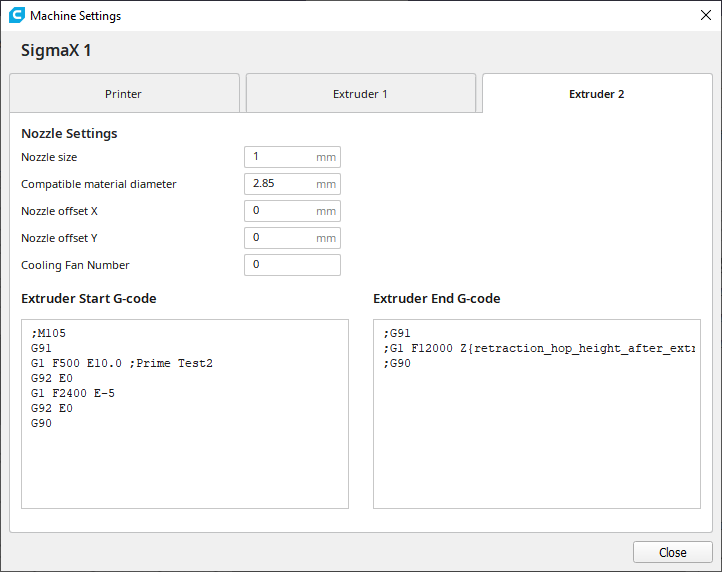

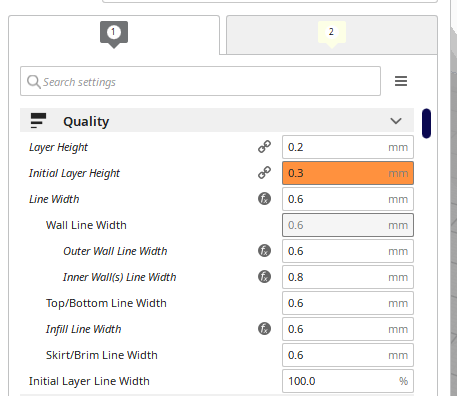

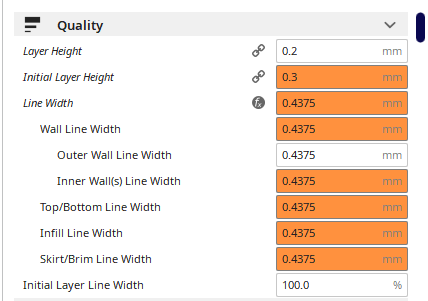

Cura should have no issue setting different nozzle diameters, unless I'm completely missing something with your setup. In Cura you can easily set the nozzle diameter for different extruders, and then from there also modifiy extrusion widths.

As an example an IDEX machine with two different nozzles (.4mm and 1mm)

A warning, the two images below aren't a perfect example because of the profile I have set, but it shows what I mean - not only different nozzle diameters configured, but different line widths.

Regarding S3D Processes (I have not used S3D but read about how they work... I think) - you can do similar model manipulations (depending on your job) by changing what parts of a model are made by what extruder, e.g. outer walls with Extruder #1, infill with Extrudr #2, support with Extruder #3, just by using the standard settings. You can also do more advanced modifications with the "Per Model Settings" feature ("Normal Model", "Print as Support", "Modifiy settings for overlaps", "Don't support overlaps").

-

@sebkritikel thanks, will look at it again. It must be a somewhat recent addition. I couldn't do this before -- I'll need to look at it again. Though it seems odd that depending on the time of day random conditions -- this print works or doesn't . Btw -- I am running THE EXACT same print on my modified series 1 (1 extruder) -- running a smoothieboard (azteeg something) -- controlled by octoprint and it runs perfectly fine.

I'm almost thinking I should just ditch duet's native gcode feeder and switch to octoprint. Kinda makes the screen from duet useless. -

@Phaedrux I really don't want to turn this into an S3D vs Cura debate. That never goes well. I've ran this print with no issues 3 times yesterday -- then the 4th had underruns. If it's a hadware fault -- I can swap the duet 2 -- I don't have the time to setup duet 3 now with swapping expansion boards and so on. If this isn't a firmware bug, that's the only answer left. I've gone through 4 SD cards. I'm using a branded sd card now. I don't know what else to do.

-

@kazolar said in Duet 2.05 memory leak?:

S3D vs Cura debate

Not the intention. Just trying to chase things down.

-

@Phaedrux I have approval from my employer (they're sponsoring the costs of producing PPE) to swap the board if that what needs to happen, or go the duet 3 route (they also agreed to cover the cost of that), but that rewire job is not something I am comfortable doing now since it will put the machine out of commission while we still have a significant need for PPE. I've personally produced 810 complete shields -- and our group of 3 printers (people) + 1 logistics person has delivered over 1600 shields together, as you can see I am responsible for more than 50% of our production -- because of the quad (QuadZilla) being able to produce shields in large batches.

If you guys tell me OK -- the board is off warranty we can't offer an RMA, and getting new one will fix it -- I'll place the order to filastruder today -- and get it before the end of the week, and 1 hour rewire I'll be up and running. I'm working from home so going to the basement every few hours to cycle prints isn't critical, but dealing with underrun errors takes more time than i should really be putting in during the day. -

Well we'd certainly like to get to the bottom of this one, and unfortunately that would probably require some more disruptive troubleshooting than would be ideal given the situation.

Please hold off for the moment while we see what we can do.

-

@kazolar I have just skimmed the thread - thanks for the persistence here, can I attempt to summarise to be clear where we are at:

- This problem occurs with 2.05.1 (with your modifications) but not with 2.03 RC2?

- When it happens its repeatable (i.e. it happens at the same point (after 30 minutes) but not every time, can you still provoke it by resetting, or not resetting the board, or any other action?

- Are you still seeing large numbers of underruns when the problem occurs? Maybe check underruns at the same point in time after the start of a print (30 minutes?) to see if there is a correlation.

- You are not able to test this with gcode generated by another slicer? and it only occurs when printing in triplicate mode?

-

@T3P3Tony

1 - it's reproducible with 2.03 RC 2 as well. Curiously enough I did a bunch of triplicate prints in the summer with this version with no issues, so I tried it -- but problem happens there as well.

2 - semi reproducible -- seems that if I keep printing the same file, and the 3rd or 4th print of the same file will trigger the issue. Resetting the board doesn't help. Seems making a fresh copy of the same exact file -- or formatting card (even without resetting or powering the board down, formatting requires a power down) -- gets it to a working state (as it's now)

3. When the problem occurs and I see stuttering -- underruns go into triple digits very quickly, last night 4th print -- at 27 minute mark it was fine, I thought I was in the clear. I was watching a movie -- I checked my phone 10 minutes later underruns were at 200+ It's technically exactly 30 minutes after the lead screw compensation finishes -- it may take a couple of minutes from the moment I hit start to when all temps stabilize and it will do the probing routine. So it's technically closer to 32 --33 minutes, but the 30 minute mark is right after the screen displays the result of lead screw compensation.

4. Setting up this print with another slicer is going to take some time. I have very specific settings in S3D which are tuned to produce these shields as fast as possible. Triplicate mode differs from duplicate primarily that the 2nd Y gantry (technically U) is involved, and printer vibrates more -- it's 200lb machine, but the gantries are more akin to CNC gantries so -- there is a lot of force involved.

I've not had it happen in duplicate mode, but I've only ran duplicate prints a couple of times, it seems to take 3-4 prints to basically render the file unprintable.

5. Whatever it's worth -- with 2.05 -- If I did anything (that involves movement) -- even try to home the machine prior to starting this triplicate print -- I'd get this behavior -- 30 min after lead screw compensation it would start getting underruns and my approach was to simply reset the board -- pre-heat, clean the nozzles -- I need to clean at least tool 0 -- I use piezo to probe. Then I'd start the print and that worked for a while..then even that stopped working and only thing that would resolve things is clean copy or card reformat.

6. Yesterday I had the most success -- 3 error free prints in a row after I formatted an 8 gb sandisk card with 32kb cluster size. After the failure i switched to the new 32gb sandisk card I got yesterday formatted with 64kb cluster size. The first print with that card was fine, 2nd I tried this morning -- didn't work. I deleted the -- uploaded a new copy -- it's running fine 3 hrs 36min -- no underruns worth noting (22 at the beginning, but no ill effect from them), 0 since. -

@kazolar you are not running stock firmware right? you are patching it and compiling yourself?

running few prints using octoprint instead from duet sd card would imo for sure completely remove sd card from the picture (or prove it has to do with sdcard/sdcard socket) so that might be a good test.

as for the processes and extruders ideamaker started as a copy of s3d so has most stuff s3d has + some stuff extra, you might want to test it out. it is not open source but it is free

-

@arhi Yes, I'm compiling my own firmware, this firmware has done successful 40 hour prints with thousands of tool changes. So if I had a bug in the patch I've been moving from each version, I'd have seen it by now. This patch by the way is like 8 lines -- as a programmer you can screw stuff up in one line, but my changes are really minor.

I could setup a pi as test unit. If I get more underruns today on the next print, I'll do that tonight. -

@kazolar said in Duet 2.05 memory leak?:

1 - it's reproducible with 2.03 RC 2 as well. Curiously enough I did a bunch of triplicate prints in the summer with this version with no issues, so I tried it -- but problem happens there as well.

Ok, and you cant try 3.01 b/c you need to port your change?

2 - semi reproducible -- seems that if I keep printing the same file, and the 3rd or 4th print of the same file will trigger the issue. Resetting the board doesn't help. Seems making a fresh copy of the same exact file -- or formatting card (even without resetting or powering the board down, formatting requires a power down) -- gets it to a working state (as it's now).

3. When the problem occurs and I see stuttering -- underruns go into triple digits very quickly, last night 4th print -- at 27 minute mark it was fine, I thought I was in the clear. I was watching a movie -- I checked my phone 10 minutes later underruns were at 200+ It's technically exactly 30 minutes after the lead screw compensation finishes -- it may take a couple of minutes from the moment I hit start to when all temps stabilize and it will do the probing routine. So it's technically closer to 32 --33 minutes, but the 30 minute mark is right after the screen displays the result of lead screw compensation.Combination of #2 and #3 is utterly bizzare to me. Do you run the Z levelling before each print, or just on start up? if its between each print what happens if you run it once on startup, then follow your new file process, and then do not repeat the Z levelling?

Also have you tried downloading the file once it starts giving the errors (preferably without a reset) and then comparing the file on the SD card with the copy on your PC?

- Setting up this print with another slicer is going to take some time. I have very specific settings in S3D which are tuned to produce these shields as fast as possible. Triplicate mode differs from duplicate primarily that the 2nd Y gantry (technically U) is involved, and printer vibrates more -- it's 200lb machine, but the gantries are more akin to CNC gantries so -- there is a lot of force involved.

I've not had it happen in duplicate mode, but I've only ran duplicate prints a couple of times, it seems to take 3-4 prints to basically render the file unprintable. - Whatever it's worth -- with 2.05 -- If I did anything (that involves movement) -- even try to home the machine prior to starting this triplicate print -- I'd get this behavior -- 30 min after lead screw compensation it would start getting underruns and my approach was to simply reset the board -- pre-heat, clean the nozzles -- I need to clean at least tool 0 -- I use piezo to probe. Then I'd start the print and that worked for a while..then even that stopped working and only thing that would resolve things is clean copy or card reformat.

- Yesterday I had the most success -- 3 error free prints in a row after I formatted an 8 gb sandisk card with 32kb cluster size. After the failure i switched to the new 32gb sandisk card I got yesterday formatted with 64kb cluster size. The first print with that card was fine, 2nd I tried this morning -- didn't work. I deleted the -- uploaded a new copy -- it's running fine 3 hrs 36min -- no underruns worth noting (22 at the beginning, but no ill effect from them), 0 since.

What does the MCU temperature read when you are 30+ minutes into a successful print, vs when you 30+ minutes into a print and it starts stuttering?

- Setting up this print with another slicer is going to take some time. I have very specific settings in S3D which are tuned to produce these shields as fast as possible. Triplicate mode differs from duplicate primarily that the 2nd Y gantry (technically U) is involved, and printer vibrates more -- it's 200lb machine, but the gantries are more akin to CNC gantries so -- there is a lot of force involved.

-

- my changes are really small, moving from 2.05 to 2.05.1 took about 20 minutes, mostly it sorting out the different dependancies so I can compile it, applying my changes is equivalent of apply patch, compile -- but to try 3.01x I'd need to sort out the building of it (that part usually takes the most time), and AFIK there are some differences in 3 vs 2 in regards to movement and command orders -- I had linked my startup config gcode earlier and you can see if anything in there is not compatible with v3

- The machine homes before each print -- the is a homing switch on all independent lead screws -- the it runs g32 -- which does the probing to do lead screw compensation -- i do it this way so the position of the bed is known prior to running lead screw compensation, so yes it does it for every print -- because after the print one of the last commands is m18 -- so then we're no longer at a known state. Homing z gets all the lead screws close -- my Z compensation adjustments are < 0.5mm -- I adjusted those end stops to be as close to reality as possible.

- I have not tried to download the file -- good idea. A print just completed and I am about to start another one -- and in 30-32 minutes after that I'll know where I stand. My MCU never goes above 29c -- I have 2 40 mm fans blowing across the board -- I can run the printer for 40 hours straight and the board is 20c off, and that's about as high as it goes when it's active, voltage is rock solid 24-24.7 -- it's a 600w PSU, printer never uses more than 300w -- the bed is AC.

Stay tuned, will start the next print now.

-

@kazolar said in Duet 2.05 memory leak?:

I have not tried to download the file -- good idea.

I'm curious to see the results.

Which DWC version are you using? There were some CRC checking issues in certain versions which I believe were all resolved with FW 2.05.1 and DWC 2.0.7. Are you using that combination?

-

@kazolar said in Duet 2.05 memory leak?:

m18 -- so then we're no longer at a known state. Homing z gets all the lead screws close -- my Z compensation adjustments are < 0.5mm -- I adjusted those end stops to be as close to reality as possible.

If you can remove the M18 from the ends gcode so there is no need to rehome and then see - It would be good if we can tie this down to running that Z levelling, or not.

-

@Phaedrux I actually am not a big fan of the new web UI so I'm using reprap.htm -- and that goes to 1.22.6

The DWC that is loaded is Duet Web Control 2.0.0-RC2, not to be a critic, but the new look is not my thing, i liked the old one better -- glad to still be able to use it.

@T3P3Tony

The problem is my startup gcode does that too, it goes through a cycle of putting every tool into standby -- I'd have to be very careful with what I change in these sequences. The combination tfree5.g tpost0.g -- has some odd consequences. I am not sure what's going on -- I haven't sorted that gcode out -- so I could try and cut out all but the essentials in start and stop gcode -- obviously that I can only do during the day when I'm here to observe. My plan for today is -- if it underruns again -- print is running now only a few minutes in -- I will setup octoprint and feed gcode that way -- if things work via octoprint, then it's pretty clear the fault is in the sdcard circuitry. -

@T3P3Tony by the way lead screw compensation result -- probing 5 points, center, and near each lead screw is 0.004 in the print that just started seen at all zeros before -- gotta love the single start lead screws and a milled aluminum plate.