Adjusting Z0

-

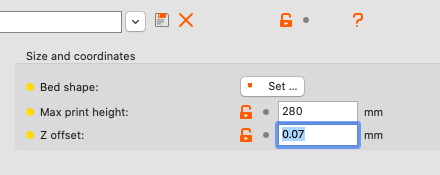

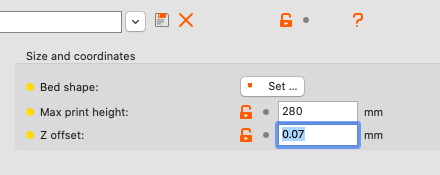

@PaulHew Another option you have to make small changes to the nozzle height is to use the slicer's settings. This is what I do.

-

@zapta said in Adjusting Z0:

@PaulHew Another option you have to make small changes to the nozzle height is to use the slicer's settings. This is what I do.

Same here.

I set it all up with G92 Z0, then I can tweak the Z offset a bit in the slicer profile for whatever filament/material I'm using. Really allows some fine tuning.

-

You can always add an adjustable Z=0 endstop. The linked design allows for 100 um adjustment per turn of the thumbwheel making small changes quick and easy.

-

This design using a micrometer, if you want to go the analog route.

-

Hi,

I never cared for the "paper" approach, too easy to crush the paper.

Instead I use a 1mm thickness gauge. Once the nozzle just touches the gauge I can use G92 1 to set the current Z position.

Frederick

-

I just eyeball it. It's well lit and at eye level so it's easy to see the gap disappear.

-

Appreciate the responses that everybody has shared.

Voron specify that when printing the parts Z must be 0 not a paper thickness 0.

Even with a 1st layer of 0.24 I still have to baby step 0.02 so it looks good and does not look like the top of a shepherds pie where the fork has been dragged through the potato!The main reason for my question is the Panel Due that is connected to this printer can only baby step in 0.02, not the 0.01 I would like, even though DWC can perform 0.01 steps. Also the printer and my computer are about 6ft away so it can get tricky.

Eyeballing the nozzle onto glass on a RailCore is tricky as there is a piece of metal in the way!

I like @fcwilt idea so will invest in some feeler gauges which is effectively what I am doing with paper but more accurately!Thanks again.

Regards

Paul

-

@PaulHew said in Adjusting Z0:

The main reason for my question is the Panel Due that is connected to this printer can only baby step in 0.02, not the 0.01 I would like

I've gotten around that by creating a macro that increments baby stepping by 0.01mm. It's a little less convenient, but it works.

@PaulHew said in Adjusting Z0:

feeler gauges

Feeler gauges are fine too, but they are also really thin and a bit hard to see, same as paper. There's nothing to say the gap being set must be small, it just needs to be accurate, so if you have a metal block that can be measured with a caliper you can use that to set the offset. Machinist blocks for instance.

-

@Phaedrux Nice one, I had not thought about that. GCode bible here I come!

P.

-

@Phaedrux said in Adjusting Z0:

Feeler gauges are fine too, but they are also really thin and a bit hard to see, same as paper.

Which is why I use a 1mm gauge. My set has thicker ones but 1mm works well for me.

Frederick