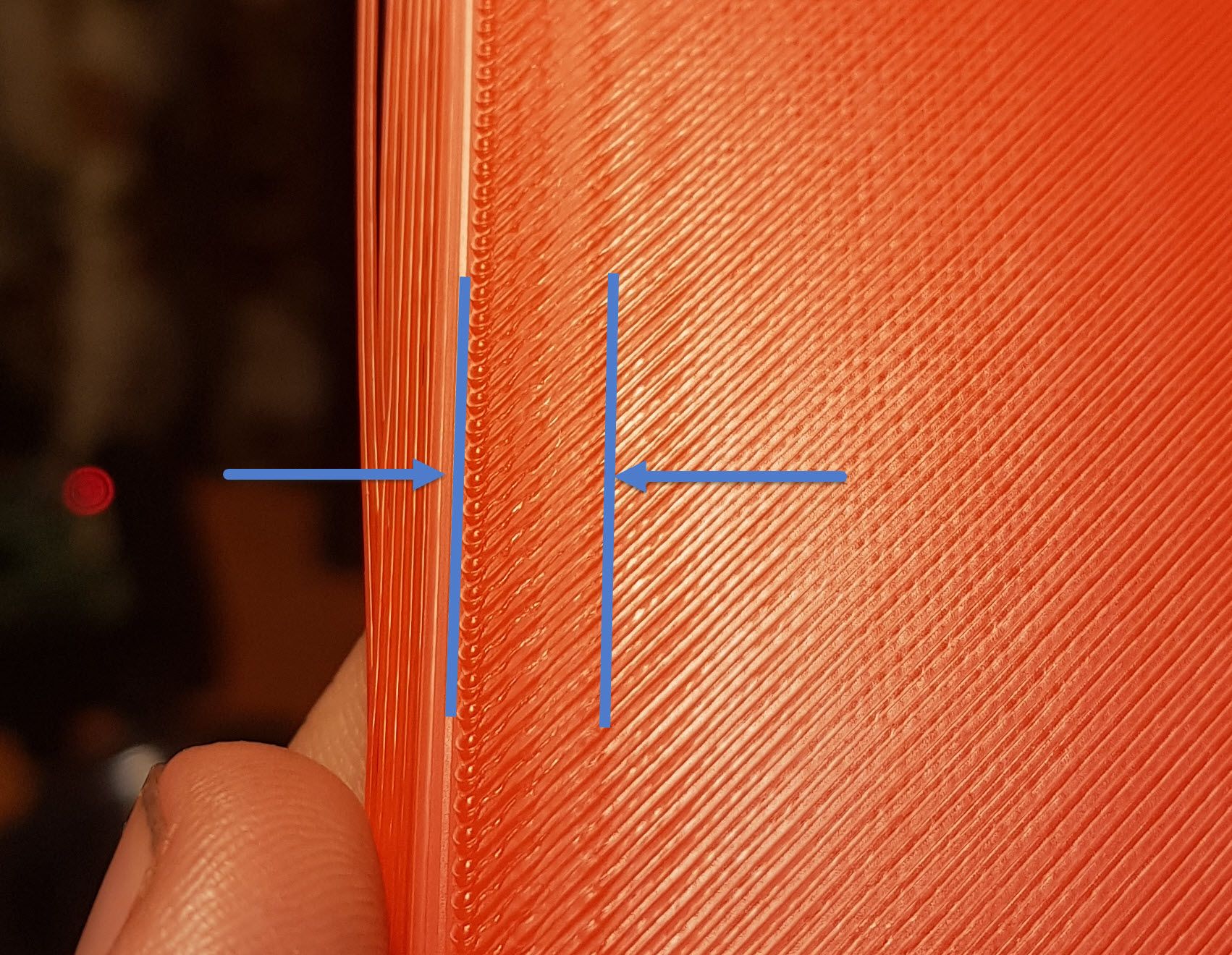

How do you get rid of these ridges?

-

Hi All,

I've been trying to tune a custom built CoreXY, and I have this region between the perimeter layers and the top/bottom surfaces that always ends up with more material than it needs. It's been a problem on all of my printers, but until now I've accepted that I had to tweak my flow settings to find a compromise with this region and the rest of my print.

Is there something I have overlooked all this time?

Thanks

-

@Gerrard Try pressure advance https://duet3d.dozuki.com/Wiki/Pressure_advance

-

@deckingman - thanks, I've been playing with pressure advance today but I didn't get anything I was happy with. I'll try a more structured approach tomorrow.

I tuned linear advance on my marlin machine and it helped with hiding the Z seam a lot, but didn't help with this problem... I was hoping for a slicer parameter that would fix both machines...

-

@Gerrard said in How do you get rid of these ridges?:

@deckingman - thanks, I've been playing with pressure advance today but I didn't get anything I was happy with. I'll try a more structured approach tomorrow.

I tuned linear advance on my marlin machine and it helped with hiding the Z seam a lot, but didn't help with this problem... I was hoping for a slicer parameter that would fix both machines...

Since you´re running a corexy, i´m going to guess that you are also running a pretty long bowden tube setup.

Chances are good that you just haven´t tried a big enough M572 (PA) value, it can easily approach 1.0 or above for long bowdens.

Just try a really big value (like, 1.5 or so) and see what it changes. If it´s too much, just dial it down.

Beginners are quick to dismiss PA because they say it doesn´t work when in reality they underestimate the amount of PA they need. -

@NitroFreak I'm actually running a very short Bowden tube - you could probably call it direct drive... it's about 1-2" between the extruder motor and the top of the hot end.

-

@NitroFreak gonna jump in and ask, what is considered a short, medium and long bowden tube?

-

@RyanP

There's a bit of a guide here.

https://duet3d.dozuki.com/Wiki/Pressure_advance -

-

If your esteps and extrusion ratio are all good, try switching off the pressure advance and use come "coasting" in your slicer.

Start at 1.5mm for bowden, and see how that looks. Then you can step it up/down by 0.5mm as you home in on a result.

I get some nice surfaces that way.