Question about significance of height map.

-

@fcwilt said in Question about significance of height map.:

I think the granite surface plate is my favorite.

i had a blast with mine, tl;dr after 2 weeks of sitting at the local depot it was returned to the UK via Oslo, then flown back to Oslo, put on a flatbed truck with a crane and driven 500km and delivered to my door after 3 weeks for a 2-3 days express delivery because health and safety here say people can't lift more than 25kg without using a crane.

(expression of mailman when he asked "what is it" and I replied "a granite "rock". a very flat rock mind you" = worth the wait)

top tip, get one with some sort of leveling system, as drilling holes to attach adjustable feet is a "¤#"#¤&%" pain.

-

@fcwilt it could well be the rails. From your CAD, it seems they are bolted straight to the extrusion? Do they bolt to T-Nuts or have you drilled them?

I've found it hard to get the two y-extrusions perfectly parallel. On top of that, they usually aren't very flat, and if you have drilled them, they will have likely deformed slightly. This can then bend the rail itself a little (though your rails look pretty hench so maybe not?) -

I'm not so sure you've got a real problem with that plate. I think you just need to use more test points when you run the manual bed leveling assistant. The assistant will then average the error over the entire surface and give you the best leveling adjustment. I use 9 points on the bed surface with the assistant and it works great.

Do you have any idea how hard it is to bend a 6 mm thick piece of aluminum? You can forget about damage in shipping, unless they drove a truck over it, which you'd see by the tire tracks on the box.

-

@bearer said in Question about significance of height map.:

(expression of mailman when he asked "what is it" and I replied "a granite "rock". a very flat rock mind you" = worth the wait)

-

@engikeneer said in Question about significance of height map.:

@fcwilt it could well be the rails. From your CAD, it seems they are bolted straight to the extrusion? Do they bolt to T-Nuts or have you drilled them?

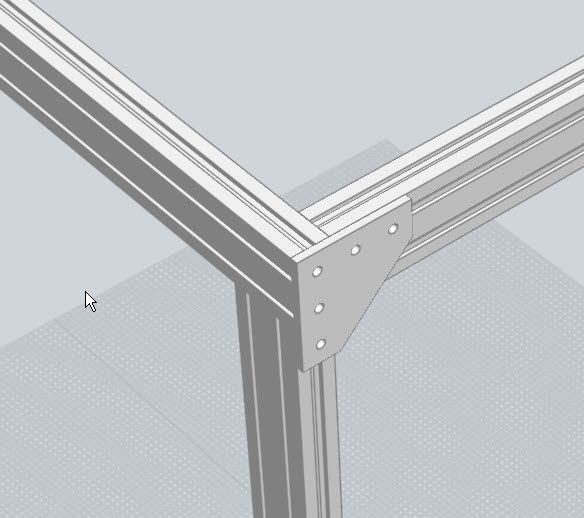

The rails are bolted to the extrusion at every other hole using this type of fastener:

I've found it hard to get the two y-extrusions perfectly parallel. On top of that, they usually aren't very flat

The extrusions are 40x20. They are bolted to the rest of the frame using those corner plates.

Shifting the rear end up slightly would be possible but it would be mostly trial and error.

I was not able to think of any way to insure the two Y rails are parallel using the tools I have on hand.

Now if I had access to that granite plate...

Thanks.

Frederick

-

Hi,

Thanks. I am going to run the assistant again using more points.

And good to know the plate is likely as flat as it was when it left the vendor.

Frederick

-

can you rotate the plate 90,

190180 or 270 degrees?(or even clamp a piece of mirror to it, non reflective side up, if the sensor in use would trigger off it?)

-

Hi,

Well it turns out it was an issue with the left Y rail not being parallel to the right Y rail.

I had to way to compare them directly but I was able to mount a dial indicator measuring the height of the very end of the left rail relative to the top of the rear horizontal extrusion.

Adjusting the rail height was still trial and error (adjust, level, create height map, analyze, repeat) but at least I was able to adjust the rail in known amounts.

It turned out that a 0.001 inch adjustment made a significant difference.

The total adjustment I made is unknown because the idea of using the dial indicator came AFTER I had made the first adjustment where I tried to match the alignment of the tops of the left and right extrusions to the horizontal extrusion.

My bad.

In any case the "droop" in the left rear corner is gone. The bed is not perfect but the four corners are within 0.02 mm which is the best I have ever achieved.

And I am going to settle for that for fear of screwing something up by striving for "perfection".

Thanks to all for the help.

Frederick

-

@Phaedrux

Where did you order your plate from?I've often considered getting a metal bed plate with magnets built in to replace.the glass.bed + buildtak magnet sticker for my 310mm circle plate but I haven't found anywhere willing to make it and certify flatness.

-

@Baenwort said in Question about significance of height map.:

@Phaedrux

Where did you order your plate from?This is what I purchased:

https://www.midweststeelsupply.com/store/castaluminumplateatp5

Frederick

-

@Baenwort said in Question about significance of height map.:

@Phaedrux

Where did you order your plate from?In Canada from here: https://www.alustock.ca/MIC6-Aluminum-Cast-Plate

-

Thanks, I've emailed to see if they will do round and even better if they will drill recesses for high temp magnets to be JB Welded in.