thermistor bad reading

-

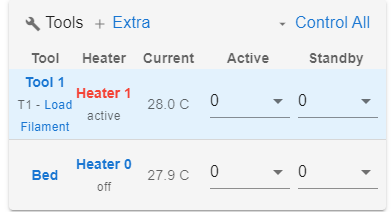

good evening everyone. I open this topic because I realized that the sensors of the bed and the hotend show temperatures that are not quite correct already at room temperature. the thermistors are of the type NTC 100k 3950. have you already faced this problem? thanks in advance

-

ntc 3950 are really bad

the beta value of 3950 refers to the temperature range from 25-50 degrees.

Beyond that it changes from thermistor to thermistor. you can easily have temperature differences of 20C

if you want accurate readings i recommend semitec-104nt or pt1000

-

@ninni Duet type? Firmware version? config.g, or at least thermistor configuration? How much temperature difference are you actually seeing? Please supply at least some useful information so that we can help you! See https://forum.duet3d.com/topic/5909/guide-for-posting-requests-for-help

For general thermistor information, see https://duet3d.dozuki.com/Wiki/Connecting_thermistors_or_PT1000_temperature_sensors

If you suspect the Duet or firmware, try putting a 100k ohm resistor on the Duet temperature pins, and see what temperature it reports.

Ian

-

This post is deleted! -

@Veti may you link me the website where i can buy it?

-

-

@ninni said in thermistor bad reading:

@Veti may you link me the website where i can buy it?

-

@Phaedrux sorry i dont understand

veti said me that semitec-104nt o pt1000 is very ood sensor -

This post is deleted! -

@droftarts ; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X200.00 Y200.00 Z800.00 E873.08 ; set steps per mm

M566 X600.00 Y600.00 Z18.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z240.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z100.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y210 Z210 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-low endstop for high end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-low endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P1 C"zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X0:22 Y0:22 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S250 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T1 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P1 D0 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T1 ; select first tool -

@ninni said in thermistor bad reading:

@Phaedrux sorry i dont understand

veti said me that semitec-104nt o pt1000 is very ood sensorI linked you to the E3D Semitec-104GT thermistor cartridge which is what I think Veti was referring to. I don't think you'll find a better or easier to obtain thermistor with known values and appropriate form factor.

-

@Phaedrux ok tu so Much

-

Does your hotend heat block take a cartridge thermistor or a glass bead?

-

@Phaedrux block thermistor

-

Does it look like the little metal tube in the E3D link above, or does it look like a little glass bead?

-

@Phaedrux small metal tube

-

Then that E3D thermistor is the one you want.

-

https://de.aliexpress.com/item/32859917151.html

this is the alternative pt1000

-

@Veti ok we Will see

-

also I would like to report a bug. when the endstop is positioned upwards for the z axis the platter stops when it touches the endstop but if you give the command again it continues to rise ignoring that the limit switch was already pressed

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 26 2020 13:33:30 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-235 Y-215 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X-235 ; home X axis

G1 H1 Y-215 ; home Y axis

G1 X5 Y5 F6000 ; go back a few mm

G1 H1 X-235 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y-215 ; then move slowly to Y axis endstop

G1 H1 Z205 F360 ; move Z up stopping at the endstop

G90 ; absolute positioning

G92 Z0 ; set Z position to axis maximum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 26 2020 13:34:47 GMT+0200 (Ora legale dell’Europa centrale)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Z205 F1800 ; move Z up until the endstop is triggered

G92 Z0 ; set Z position to axis maximum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioningconfig.g

; Axis Limits

M208 X0 Y0 Z-200 S1 ; set axis minima

M208 X230 Y210 Z0 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop