After Micro swiss DD upgrade,Extruder skips steps

-

yeah that is why i dont like B3950 thermistors. the reported temperature can be way off.

-

@Veti so the Problem is the thermistor?

So i will wait the New one

-

most likely yes.

-

i have installed the new thermistor but i can print pla with 235°C i dont now why

-

@lui2004

its not uncommon for the 3950 to be off by 20Cdid you change the beta and C value?

-

i have installed the Semitec 104GT-2 today

my config for this :

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 300C M307 H1 B0 S1.00 -

thats the thermistor: 104NT-4-R025H42G Semitec Thermistor 100K - NTC

i checked the datasheet and the B Value seems to be: 4267 ?

datasheet:

https://reprapworld.de/datasheets/NTCThermistor_NT-461415.pdf -

@lui2004 said in After Micro swiss DD upgrade,Extruder skips steps:

i checked the datasheet and the B Value seems to be: 4267 ?

B and C change the algorithm to steinhart hart. its more accurate.

see the table

-

the config is also ok like that ?

-

yes, but its still strange that you need 235 to print pla.

do you have a steel nozzle?

-

yes, hardened steel with Micro Swiss all metal hotend

-

@lui2004 ]

ok steel nozzle a very bad for printing pla. the thermal transfer is very low.

unless you are printing abrasive materials, a brass nozzle is a lot better.

or if you want a much better nozzle, there are copper plated nozzles

https://de.aliexpress.com/item/4000007458595.html -

i print only PLA and Petg

-

then there is no need for a steel nozzle

-

Ok i have a cooper plated, i will change now and test it

-

I have changed the nozzle and Calibrated all, all works fine now.

I can print PLA with 200°C! Thanksi have another question i have Bed compensation in use: none is this normal ? i thin it should be mesh or not ?

if you need config.g or slicer start.gcode or anything else tell me i will post it

-

for that your G29 needs to be executed after the G28 in the slicer start code

-

my start.gcode looks like that:

T0 G90 ;absolute positioning M107 ;start with the fan off M83 ; extruder relative mode M104 S[first_layer_temperature] ; set extruder temp M140 S[first_layer_bed_temperature] ; set bed temp ; Homing & leveling G28 M561 ; Clear any bed transform that might be in place G1 X73 Y106 F4000 ; Go to bed center before probing ;Wait for Temperature M109 S[first_layer_temperature] ; wait for extruder temp M190 S[first_layer_bed_temperature] ; wait for bed temp G30 ; Find the Z=0 G29 S1 ; Load the height map from the last time I used G29 to probe the bed. G1 X5 Y10 Z0.2 F3000 ; get ready to prime G92 E0 ; reset extrusion distance G1 X160 E15 F600 ; prime nozzle G1 X180 F5000 ; quick wipe -

this should activate the mesh compensation

do you have a heightmap it can load?

-

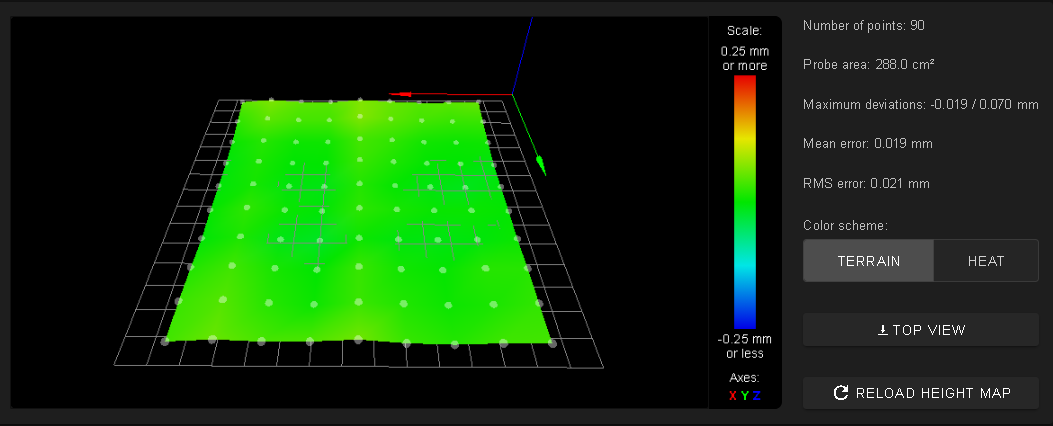

yes of course!

RepRapFirmware height map file v2 generated at 2020-12-15 08:54, min error -0.019, max error 0.070, mean 0.019, deviation 0.021 xmin,xmax,ymin,ymax,radius,xspacing,yspacing,xnum,ynum 41.20,219.00,15.00,195.00,-1.00,20.00,20.00,9,10 0.055, 0.048, 0.046, 0.056, 0.070, 0.048, 0.050, 0.068, 0.048 0.030, 0.029, 0.036, 0.050, 0.070, 0.037, 0.037, 0.050, 0.024 0.007, 0.005, 0.009, 0.026, 0.037, 0.007, 0.006, 0.020, 0.004 -0.008, -0.001, 0.001, 0.015, 0.031, 0.001, -0.001, 0.014, -0.005 -0.004, -0.014, -0.008, 0.002, 0.019, -0.010, -0.006, 0.011, -0.004 0.002, 0.005, 0.004, 0.012, 0.024, -0.003, 0.005, 0.025, 0.002 0.005, -0.005, -0.009, -0.006, 0.006, -0.019, -0.011, 0.015, -0.003 0.021, 0.020, 0.002, 0.009, 0.030, -0.000, 0.012, 0.034, 0.017 0.027, 0.014, 0.006, 0.017, 0.031, 0.006, 0.020, 0.045, 0.031 0.036, 0.034, 0.019, 0.030, 0.061, 0.041, 0.039, 0.056, 0.035