leadscrew vs ballscrew

-

@deckingman said in leadscrew vs ballscrew:

He made no mention of different diameters. That's what I was commenting on. Of course a bigger screw and bigger nut will behave differently but that's not what the OP said.

omni uses bigger screw (10x1x2) and mentioned how harder it was to line up and you replied to his post

.. all clear now

.. all clear now -

@CaLviNx said in leadscrew vs ballscrew:

mind you i have a few years of experience of straightening hydraulic rods offshore.

that might be it!

-

I use two (lightly used) Bosch Rexroth ballscrews (floating bearing one side, angular contact bearings the other side) in conjunction with two (lightly used) IKO LWHT15 linear rails for my Z axis, and couldn't be happier.

Those options aren't cheap though, especially at 900mm long. I think a nice belt driven setup would give you the results you need.

-

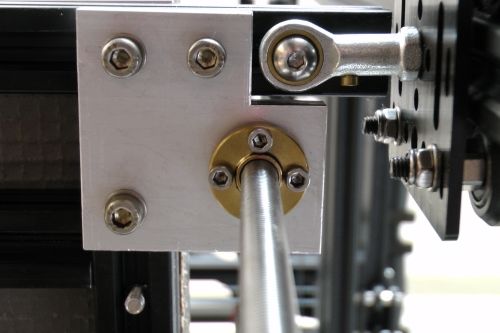

@arhi Regarding the issue you had with alignment, I use the lead screws to level the bed, not just lift it. That is to say, I have no levelling screws - I simply slacken the grub screws holding the pulleys to the lead screw, rotate the screw, then tighten the grub screws. Of course, I turned down a section of the lead screw so that the pulley fits over an unthreaded section. Because of that, I needed to have some "float" so that the nuts don't "bind" before the bed is levelled. So I use an "O" ring between the nut and the block that attaches to the build platform, and longer bolts with Nyloc nuts. The nuts are tightened just enough to start to compress the "O" ring. Here is a picture

And this is the part fitted to the machine

Prior to levelling, the build platform might not be truly at right angles to the lead screws, but this arrangement prevent the nuts from binding because of the "float" allowed by compressing one side or other of the O ring.

-

@deckingman said in leadscrew vs ballscrew:

@arhi Regarding the issue you had with alignment

Not me, I know the machine where the changes were made and I assisted a bit but it's omni who did it all and he finally turned that D9 into next level machine

... I personally never used 10mm leadscrews, I used 8mm "screw", 8mm acme leadscrew in 8x1x2, 8x2x2, 8x4x2 and 8x1x8 configuration and 1605 ballscrew (and some bigger ballscrews but not on 3d printers) so neve tried the 10x1x2 omni used (and he chose those as those were available locally, 8x1x2 he wanted were not available locally... so all the binding experience is his, I only experienced it trough viber

... I personally never used 10mm leadscrews, I used 8mm "screw", 8mm acme leadscrew in 8x1x2, 8x2x2, 8x4x2 and 8x1x8 configuration and 1605 ballscrew (and some bigger ballscrews but not on 3d printers) so neve tried the 10x1x2 omni used (and he chose those as those were available locally, 8x1x2 he wanted were not available locally... so all the binding experience is his, I only experienced it trough viber  trying to help with some ideas and suggestions and printing some parts omni designed while his printer was inoperable... mine machines are lot different design so I never had that type of a problem

trying to help with some ideas and suggestions and printing some parts omni designed while his printer was inoperable... mine machines are lot different design so I never had that type of a problemSo I use an "O" ring between the nut and the block that attaches to the build platform, and longer bolts with Nyloc nuts. The nuts are tightened just enough to start to compress the "O" ring.

that's a nice idea, to solve the angle problem. It would not solve the XY wobble IMHO but that would allow for god variance in an angle so that nut does not bind

good share, thanks

good share, thanks -

@arhi said in leadscrew vs ballscrew:

that's a nice idea, to solve the angle problem. It would not solve the XY wobble IMHO ...........................

Er no - controlling XY wobble is the job of the linear guides, not the lead screws.

-

@deckingman said in leadscrew vs ballscrew:

Er no - controlling XY wobble is the job of the linear guides, not the lead screws.

yes, on proper designs... but I'm around since the beginning and on the old designs (read Darwin) the XY wobble due to bent Z rods was a big deal and different XY "arrests" were made ... none of them very good... finally the designs started to look more like standard cnc machines where all those issues are sorted long time ago

-

well i got some pulley and belt , here a more define version of the pulley box i kept a possibility to had a second motor if 1 is not enough .9 degree stepper with 20>60>20>60

should give plenty of strength and e step as well , if i calculated accurately one set of pulley should give 480 e-step adding the second should be 3x that so 1440 e-step total,him my right ?

-

so only thing i need to do now to complete the conversion is to make some flat on the 5mm shaft so that the pulley doesnt roll on it , and test if that work ,

when i was removing the leadscrew once i unscrew everything it didnt look to be bend has much anymore so i guess the weight of the platform might have been too much for the tiny 8mm leadscrew making it flex on the weight ,

-

here an update did a test cube , side wall was way smoother no Z pattern anymore , bad new is the cheap mosfet i was using for the bed a connector melted , so no bed heater until i get another one , also ordered a ssr relay so i will eventually switch to that , need to print a few more thing to finalized the belt system ,